Automatic Laser Cutting Parts Polishing Sanding Machine Flat Metal Surface Deburring Machine

Ideal for industries requiring flawless finishes on laser-cut components, this machine automates surface treatment to eliminate imperfections like burrs, scratches, and oxidation. Engineered for high-speed operations, it ensures consistent quality in automotive, aerospace, electronics, and architectural metalwork. With advanced robotic controls and adaptive tooling, it reduces labor costs, minimizes material waste, and enhances productivity in demanding manufacturing environments.

Table of Contents

Automated Precision for Flawless Metal Surfaces

This machine leverages robotic automation to deliver micron-level accuracy in polishing and deburring. Equipped with programmable CNC controls, it adapts to complex geometries, ensuring uniform surface finishes on stainless steel, aluminum, brass, and other metals.

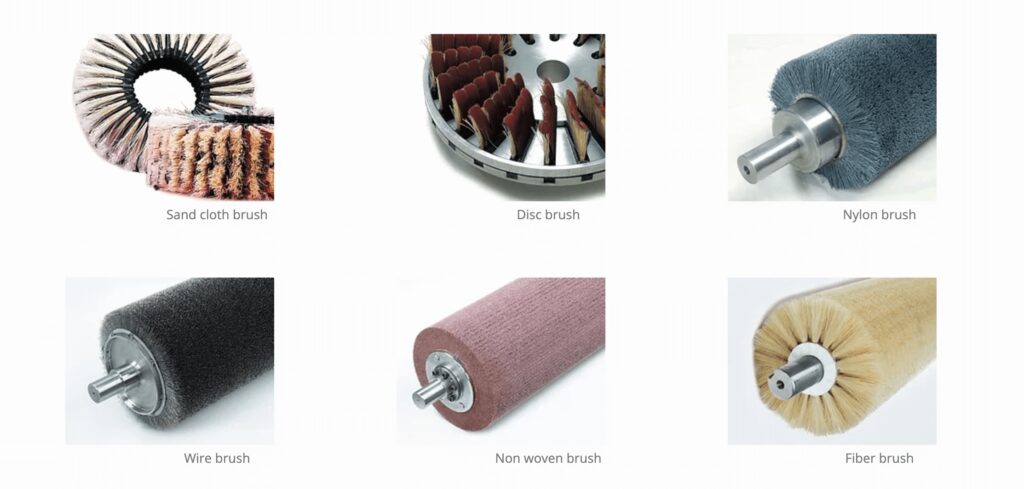

Integrated Polishing & Deburring in One System

Seamlessly transition from laser cutting to finishing with a single machine. The integrated design features adjustable abrasive belts, rotary brushes, and orbital sanding heads to handle rough edges, micro-burrs, and surface smoothing without manual intervention.

Advanced Adaptive Pressure Control

Smart sensors dynamically adjust polishing pressure based on material thickness and surface irregularities. This prevents over-grinding, preserves dimensional integrity, and extends tool lifespan.

High-Speed Processing for Industrial Workflows

Boost throughput with rapid cycle times, capable of processing large batches of laser-cut parts. The machine’s modular setup allows simultaneous polishing and deburring, cutting downtime by up to 50%.

Dust Extraction & Eco-Friendly Operation

Built-in HEPA filtration captures metal particulates and debris, maintaining a clean workspace and complying with industrial safety standards. Energy-efficient motors reduce operational costs and environmental impact.

Versatile Applications Across Industries

From automotive chassis components to intricate electronic enclosures, this machine excels in diverse sectors. Its compatibility with flat sheets, tubes, and angled edges makes it indispensable for fabricators prioritizing precision and scalability.

Conclusion

Transform your post-laser cutting workflows with the Automatic Laser Cutting Parts Polishing Sanding Machine—a game-changer in metal surface finishing. By merging robotic precision, adaptive technology, and multi-functional capabilities, it addresses critical challenges in deburring, polishing, and sanding while slashing production costs. Whether refining aerospace alloys or architectural panels, this machine guarantees unmatched efficiency and repeatability. Invest in a system that elevates quality, complies with sustainability goals, and meets the rigorous demands of modern manufacturing.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao