Automatic Deburring Machines for Sheet Metal Processing

Our automatic sheet metal deburring machines are engineered to streamline your production process while ensuring a high-quality surface finish on steel, stainless steel, and aluminum parts.

Designed for fabricators, laser cutting workshops, and OEM manufacturers, this advanced deburring metal machine reduces manual labor and improves consistency across batches—making it a must-have for modern metalworking facilities.

Table of Contents

Why Choose Our Deburring Machines for Sheet Metal?

Automatic & Continuous Deburring – Handles large volumes of metal parts with minimal operator intervention

Consistent Edge Rounding – Uniform results on all four sides, improving safety and coating adhesion

Versatile Material Support – Works with stainless steel, mild steel, galvanized sheet, and aluminum

Dual-Side Processing (Optional) – Deburrs top and bottom in a single pass

Energy-Efficient Drive System – Reduced power consumption without sacrificing performance

Compact, Industrial-Grade Design – Fits seamlessly into laser cutting and punching production lines

Our automatic sheet metal deburring machine eliminates the need for hand grinders, saving time and reducing injury risk.

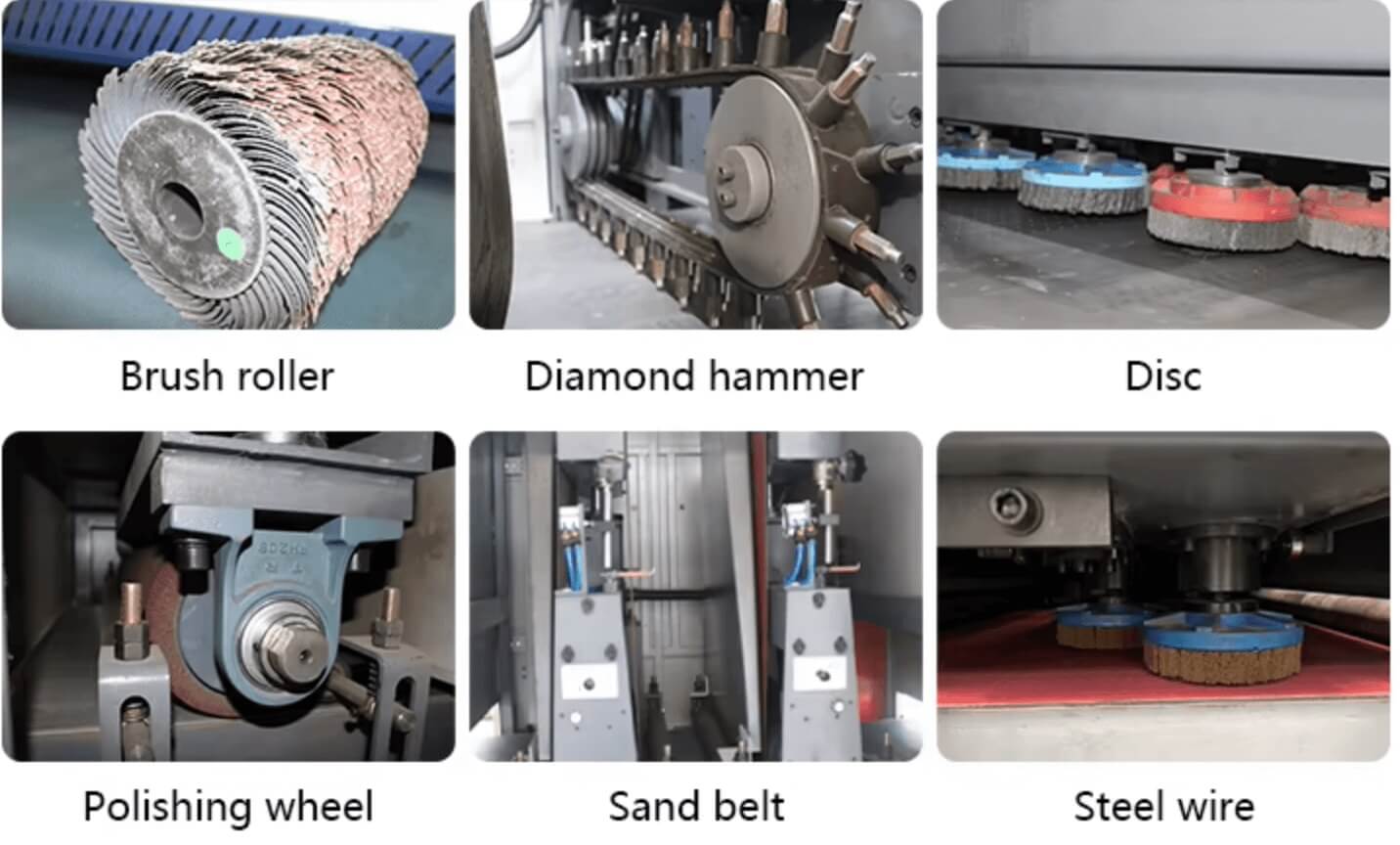

Sanding Machine for Metal: Versatility in Finishing

- Wide Working Width Options – Available in 600mm to 1300mm widths to match your sheet size

- Rotary Brush & Belt System – Combines sanding belts and rotating brushes for edge rounding and oxide removal

- Touchscreen PLC Control – Easy operation and quick parameter adjustment

- Adjustable Speed & Pressure – Customizable to handle delicate or heavy-duty applications

- Efficient Dust Collection Interface – Keeps the workspace clean and operator-friendly

- Modular Heads – Configurable deburring, grinding, and polishing stations for different needs

Whether you process punched parts, laser-cut plates, or blanked sheets, our deburring metal machines are designed for precision.

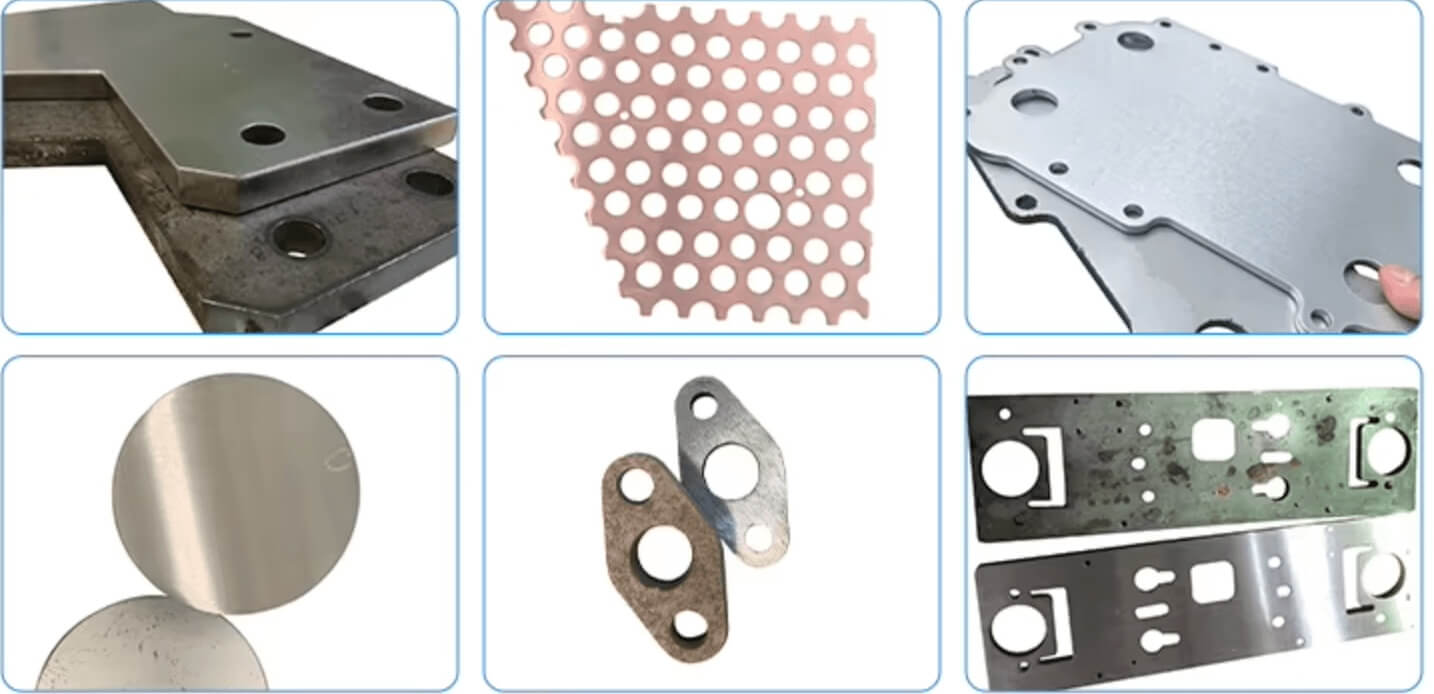

Applications in Sheet Metal Processing

Our deburring machines for sheet metal are widely used in:

- Laser & Plasma Cutting Workshops – For post-cutting burr removal and edge rounding

- Stainless Steel Fabrication – To create smooth edges and prepare surfaces for powder coating or welding

- HVAC & Electrical Enclosure Production – Clean, burr-free edges reduce assembly risk and improve fit

- Automotive & Aerospace Sheet Metal – Where precision edge quality is critical

- General Metal Parts Manufacturing – For improved surface safety and appearance

These machines help manufacturers meet high-quality standards and safety regulations.

Technical Specifications of the Automatic Sheet Metal Deburring Machine

| Parameter | Value |

|---|---|

| Max Sheet Width | 1000 mm / 1300 mm |

| Max Sheet Thickness | 0.5–100 mm |

| Deburring Method | Abrasive belt + rotary brush heads |

| Workpiece Material | Stainless steel, carbon steel, aluminum |

| Conveyor Speed | 0.5–8 m/min (adjustable) |

| Motor Power | 7.5 kW – 15 kW (based on configuration) |

| Control System | PLC + Touchscreen |

| Machine Type | Dry processing |

| Dust Collection | Built-in or external interface |

Conclusion

Investing in an automatic deburring machine for sheet metal isn’t just about removing burrs—it’s about improving efficiency, safety, and product quality. Whether you’re processing stainless steel panels or aluminum enclosures, our deburring metal machines deliver consistent, clean results with less manual effort.

Upgrade your workshop with our reliable, industrial-grade sheet metal deburring solutions and experience the difference in throughput, edge quality, and customer satisfaction.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao