Raw to Masterpiece: Synergy of Laser Cutting and Sanding Steps

Transforming raw metal into high-quality products, this synergy ensures enhanced appearance, performance, and market competitiveness.

Table of Contents

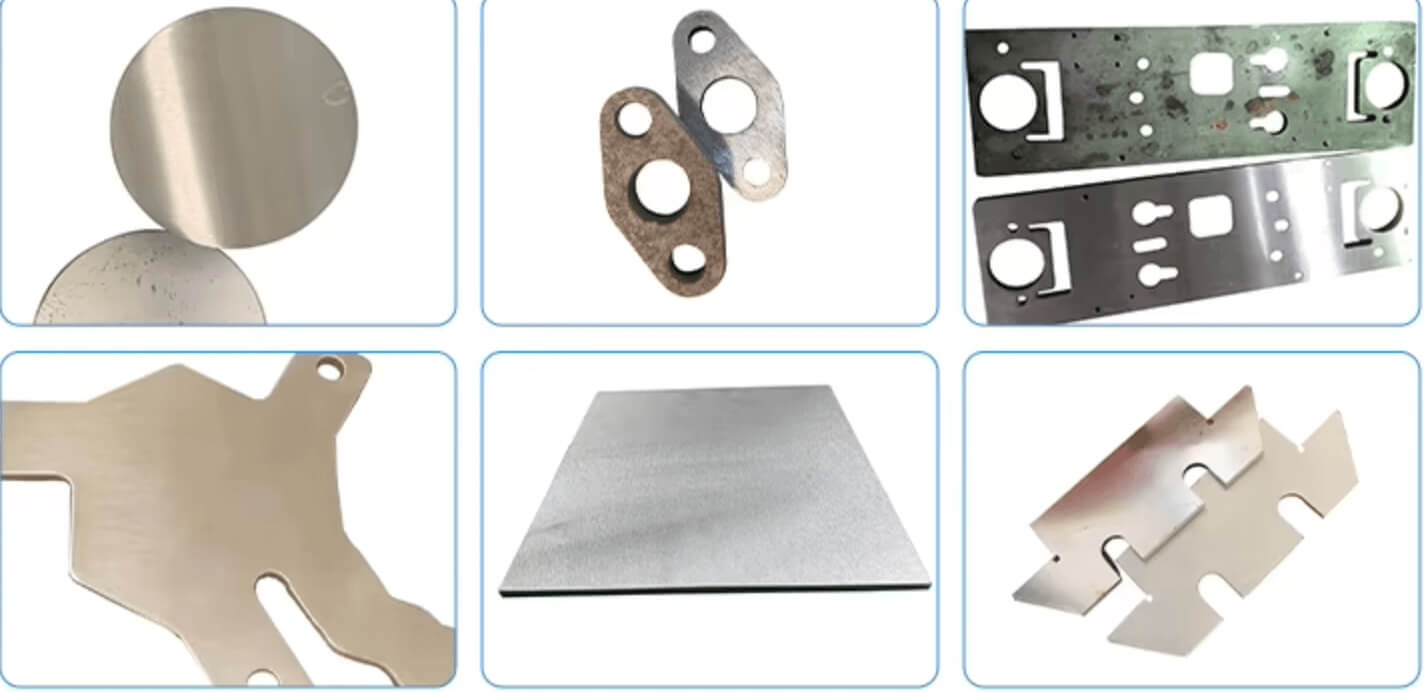

Precision Foundation of Laser Cutting

Laser cutting is renowned for its high precision, efficiency, and flexibility, capable of quickly processing complex shapes. However, post-cutting surfaces often have burrs, oxidation layers, or rough edges, which can compromise further processing and product quality.

Optimization Through Sanding Technology

Incorporating metal sanding machines effectively addresses these imperfections, taking the quality of workpieces to the next level:

- Deburring and Oxidation Removal: Sanding swiftly removes edge defects, achieving a smoother surface.

- Surface Finish Enhancement: It reduces roughness, providing a perfect foundation for coating, plating, and other finishing processes.

- Improved Safety and Aesthetics: Sanded edges are smoother, enhancing touch and eliminating sharp, hazardous corners.

Significant Benefits of Process Synergy

- Boosting Production Efficiency

Laser cutting ensures precision, while sanding quickly refines the surface, significantly enhancing overall efficiency. - Meeting Diverse Requirements

Whether working with stainless steel, aluminum, or copper, sanding technology adapts to different materials for customized treatment. - Enhancing Market Competitiveness

Superior finishing quality makes products more attractive in the market, meeting the rigorous demands of high-end clients.

Conclusion

The synergy of laser cutting and sanding is more than a combination of technologies; it’s an optimization of the entire manufacturing process. Transforming raw materials into masterpieces, this collaboration exemplifies the power of advanced production methods. By adopting innovative metal sanding machines, manufacturers can stand out in competitive markets and achieve more efficient, higher-quality production goals.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao