Aluminium Sheet Surface Grinding Buffing Polishing Machine for Inflatable Plate Evaporator

The Aluminium Sheet Surface Grinding Buffing Polishing Machine is designed to effectively address the needs of surface finishing, delivering high-quality results in deburring, rust removal, and polishing. This machine is particularly useful for aluminum sheets and plates, ensuring that they meet the stringent standards required for use in evaporators, heat exchangers, and other industrial applications.

Table of Contents

What is an Aluminium Sheet Surface Grinding Buffing Polishing Machine?

The Aluminium Sheet Surface Grinding Buffing Polishing Machine is an advanced piece of equipment designed to grind, buff, and polish the surfaces of aluminum sheets and plates. It is commonly used in the manufacturing of high-precision metal products where surface finish quality is crucial. This machine is equipped with specialized grinding wheels, buffing pads, and polishing rollers that remove rough edges, rust, and other surface imperfections, leaving a smooth and reflective surface.

In industries like the production of inflatable plate evaporators, where metal plates must be free of contaminants, burrs, and rust, this machine is indispensable for ensuring consistent surface quality. By automating the grinding and polishing process, it enhances both the efficiency and the overall quality of aluminum components.

Key Features of the Aluminium Plate Sheet Surface Rust Polishing Machine

The Aluminium Plate Sheet Surface Rust Polishing Machine is designed with several key features to maximize performance and versatility:

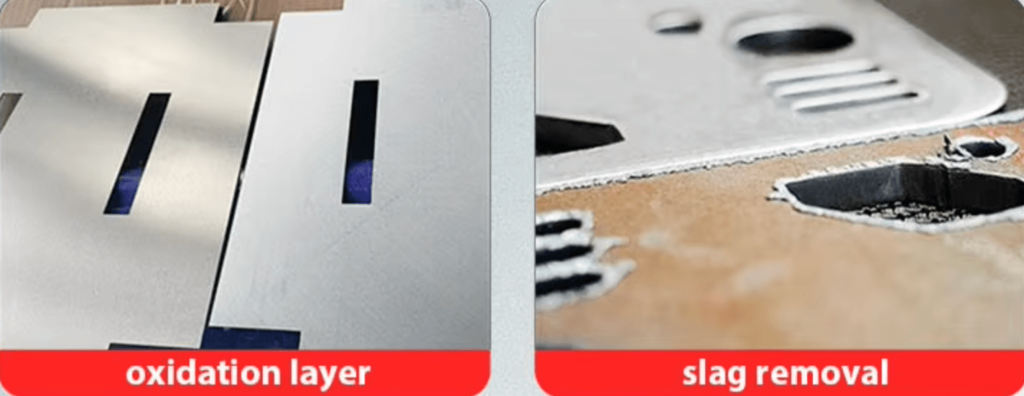

Rust Removal: One of the primary functions of this machine is to remove rust and oxidation from aluminum surfaces. With the help of high-performance grinding wheels and abrasive belts, the machine efficiently removes surface rust, ensuring that the metal is clean and prepared for further processes or applications.

Precision Grinding and Polishing: The Aluminium Plate Surface Grinding Machine integrates grinding and polishing functions, which are essential for creating high-precision, smooth surfaces. It ensures that every sheet of aluminum has an even finish, free from scratches, grooves, or imperfections.

Versatility: Whether you need to process aluminum sheets for inflatable plate evaporators, heat exchangers, or other industrial uses, this machine is versatile enough to handle various metal thicknesses and dimensions, making it an invaluable asset for many manufacturing operations.

High Efficiency: The machine’s automated system significantly reduces manual labor while increasing throughput. With precise control over grinding, buffing, and polishing speeds, it allows for uniform processing of multiple sheets or plates in a fraction of the time required by manual methods.

Benefits of the Aluminium Plate Surface Grinding Machine

The Aluminium Plate Surface Grinding Machine provides a range of advantages that make it essential for modern metalworking operations:

High-Quality Surface Finish: By combining grinding, buffing, and polishing processes, this machine ensures a superior finish on aluminum plates and sheets. This is particularly important for components like inflatable plate evaporators, where surface quality directly impacts performance.

Rust and Oxidation Removal: The Aluminium Plate Sheet Surface Rust Polishing Machine effectively removes any rust, oxidation, or impurities, which could degrade the material’s integrity or appearance. This not only improves the visual appeal but also prevents corrosion, extending the life of the metal components.

Increased Productivity: The automated nature of the machine streamlines the grinding and polishing process, reducing labor costs and increasing production capacity. Operators can process larger quantities of aluminum with consistent results, improving the overall workflow efficiency.

Cost-Effective: While the machine offers high performance, it is also designed to minimize material waste, making it a cost-effective solution for industries that rely on aluminum processing. Its efficiency in removing rust and polishing metal also reduces the need for additional finishing processes, saving both time and resources.

How the Aluminium Sheet Surface Grinding Buffing Polishing Machine Works

The process begins with the Aluminium Sheet Surface Grinding Buffing Polishing Machine grinding the surface of the aluminum sheets using abrasive wheels or belts. This removes rough edges, imperfections, and any surface contaminants. The next stage involves buffing, where polishing pads are used to refine the surface further, removing any residual abrasions. Finally, the polishing stage delivers a smooth, reflective finish, making the aluminum plate suitable for applications that require both aesthetic and functional qualities, such as in inflatable plate evaporators.

By combining these steps into one seamless process, this machine ensures that every sheet of aluminum meets the high standards required for industrial applications.

Conclusion

The Aluminium Sheet Surface Grinding Buffing Polishing Machine is an essential tool for industries that require high-quality aluminum surface finishes. Whether used in the production of inflatable plate evaporators, heat exchangers, or other metal components, this machine ensures precise grinding, rust removal, and polishing, delivering superior results with minimal effort. With its ability to efficiently process aluminum plates and sheets, it provides a cost-effective solution for businesses aiming to enhance productivity while maintaining high-quality standards.

Investing in this advanced machine helps manufacturers improve surface quality, reduce labor costs, and increase production efficiency, making it an invaluable asset for industries dealing with aluminum processing and finishing.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao