Metal Sanding Machines vs Manual Grinding: Efficiency Showdown

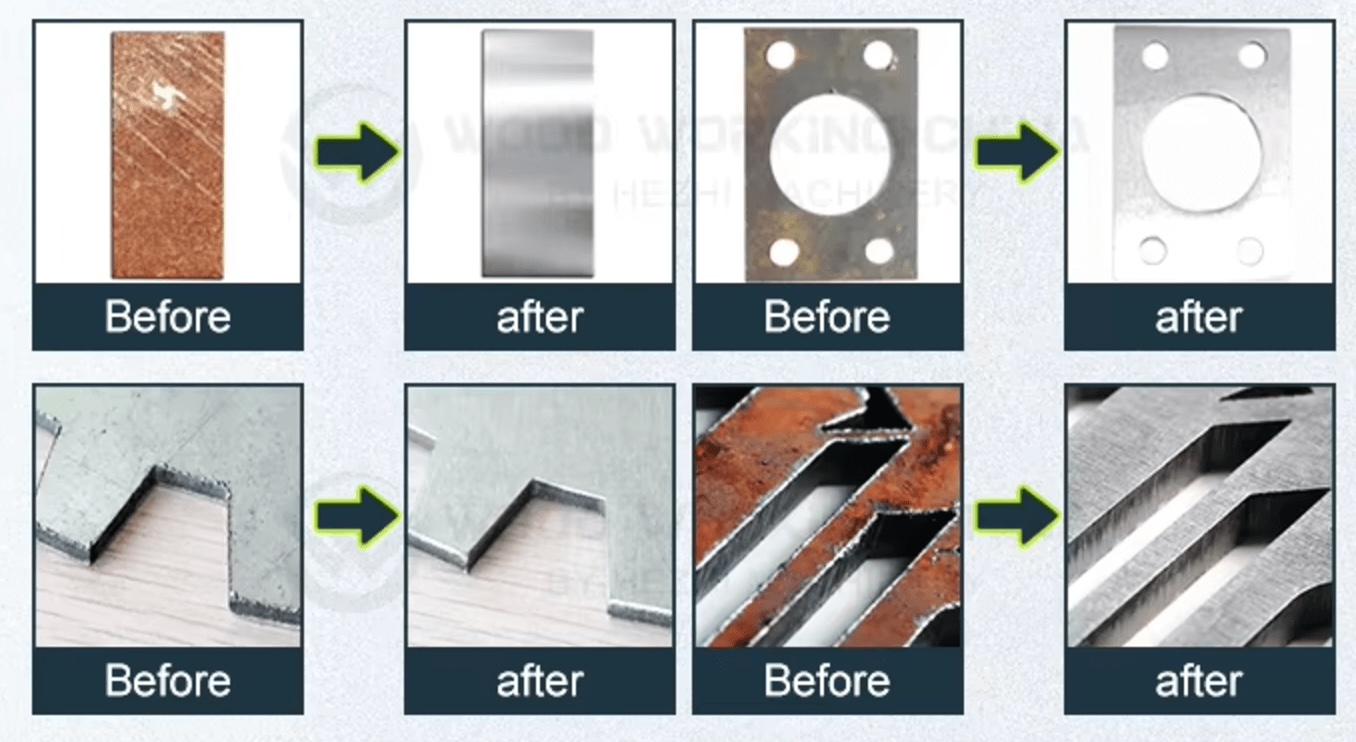

When compared to traditional manual grinding tools, metal sanding machines offer significant differences in efficiency, precision, and workload.

Here’s a comparison to help you understand which is more efficient:

Table of Contents

Efficiency

- Metal Sanding Machines: Metal sanding machines use mechanical methods to perform sanding, allowing them to complete large area or high-volume metal processing tasks in a short time. The sanding belts or discs run continuously, enabling sustained grinding, which makes them highly efficient, especially for mass production.

- Traditional Manual Grinding Tools: Manual grinding requires human operation, which is generally slower, especially when dealing with large areas or multiple workpieces. Each part needs to be manually sanded and adjusted, resulting in lower production speed and efficiency.

Precision

- Metal Sanding Machines: Metal sanding machines can precisely control parameters like sanding belt pressure and speed to ensure consistent and accurate sanding. They are especially suitable for metal parts that require high precision and can maintain uniform surface quality.

- Traditional Manual Grinding Tools: The precision of manual grinding is largely dependent on the skill of the operator. For complex shapes or parts requiring high precision, manual grinding may not achieve the same consistent results, particularly in fine detail work.

Workload and Ease of Operation

- Metal Sanding Machines: Sanding machines can run continuously, reducing the physical labor of manual operation. They are relatively easy to operate, requiring only setup and monitoring, which greatly reduces operator fatigue, especially during long working hours.

- Traditional Manual Grinding Tools: Manual tools require prolonged physical effort, especially when working with hard metals. The operator may experience hand fatigue, which can affect efficiency and comfort during long grinding sessions.

Application Range

- Metal Sanding Machines: These machines are ideal for large-scale production and can handle various complex metal part shapes, completing surface processing tasks in a short time.

- Traditional Manual Grinding Tools: Manual tools are better suited for small-scale, customized, or intricate workpieces. They are often still necessary for small production runs when machinery is not available.

Conclusion

Metal sanding machines outperform traditional manual grinding tools in terms of efficiency, precision, and workload, making them the better choice for high-volume and high-precision tasks. While manual grinding tools still have advantages in certain situations, such as custom work or small-scale production of complex shapes, metal sanding machines are more efficient overall in terms of production speed and consistency.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao