What is a Metal Sander? Its Working Principle and Applications

This type of machine is widely applied to materials such as steel, stainless steel, aluminum, copper, and brass, enhancing production efficiency and product quality. Metal sanders, also known as metal sanding machines or metal surface finishers, are highly valued in fields like decoration, metal manufacturing, and industrial services.

Table of Contents

Working Principle

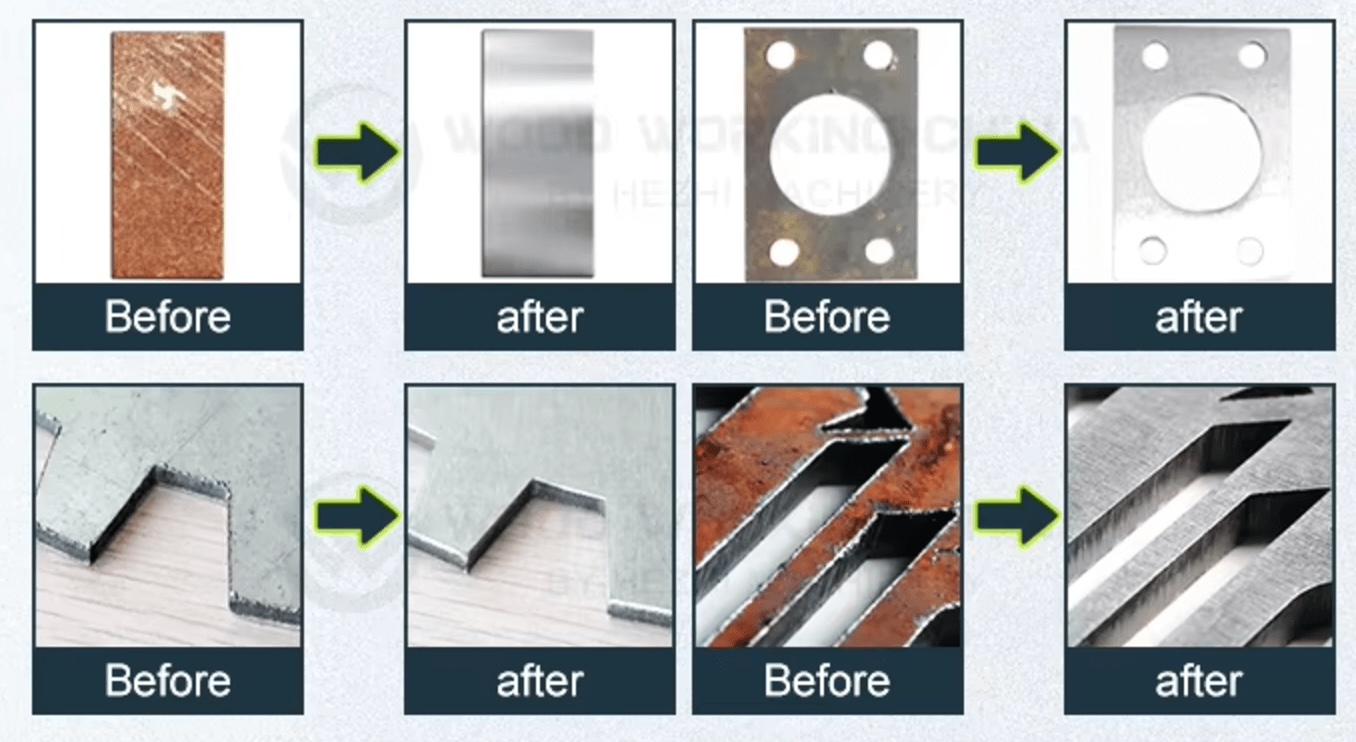

Metal sanders operate by utilizing high-speed rotating abrasive belts, wheels, or other grinding attachments to cut and refine the surface of metal materials. During the process, the machine removes surface contaminants, scratches, burrs, or discoloration to achieve a smooth and uniform finish. This efficient processing method meets the diverse surface treatment needs of different users.

Main Applications of Metal Sanders

- Surface Cleaning: Metal sanders can remove dirt, rust, and impurities from the surface of metals, ensuring material cleanliness.

- Polishing: By polishing and refining, metal sanders provide a smoother and more visually appealing surface finish, suitable for industrial polishing tasks.

- Surface Preparation: Used before applying coatings, paint, or adhesives, sanding improves surface adhesion quality, a crucial step in metal surface preparation.

- Decorative Fabrication: In decorative and artistic metal products, sanders enhance surface aesthetics and design precision, making them ideal for stainless steel finishing and aluminum polishing.

- Enhancing Component Quality: Widely used in industrial and automotive production, sanders improve the surface quality of metal components, such as metal plates, tubes, and hardware.

- Deburring and Edge Rounding: Metal sanders are effective in removing burrs and creating smooth edges, critical for safety and functionality in finished metal parts.

Conclusion

Metal sanders are indispensable in the field of metal processing, known for their efficiency, versatility, and wide range of applications. Whether for deburring, surface finishing, or polishing, these machines play a pivotal role in achieving high-quality results. By understanding their working principles and main uses, you can better select and utilize a metal sander to achieve your business objectives. Keywords like metal sanding machine, industrial sander, abrasive belt sander, and metal surface grinder are integral to finding the right equipment for your needs.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: info@metalsanders.com

- Address: Wangtai Gongye Industry, Qingdao