How to Use a 630 Metal Sander for Polishing Stainless Steel

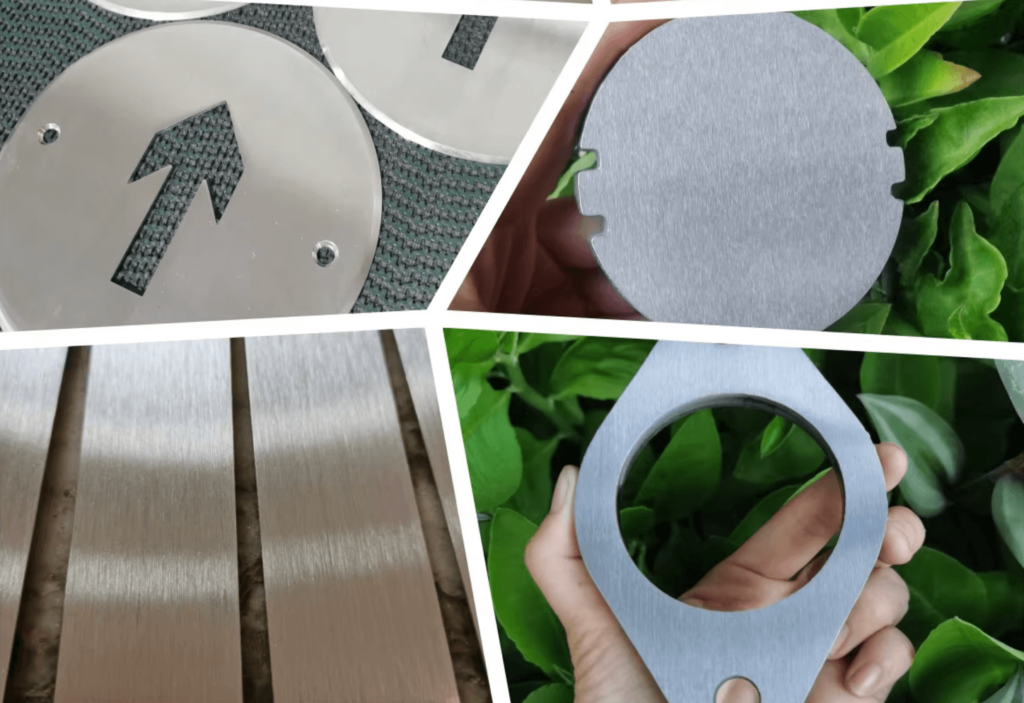

A 630 metal sanding machine is ideal for polishing stainless steel sheets or parts efficiently and uniformly.

Here’s a step-by-step guide:

Table of Contents

Prepare the Stainless Steel

- Clean the Surface: Use a degreaser to remove dirt, oil, and dust.

- Inspect for Defects: Check for scratches, rust, or weld marks that need attention.

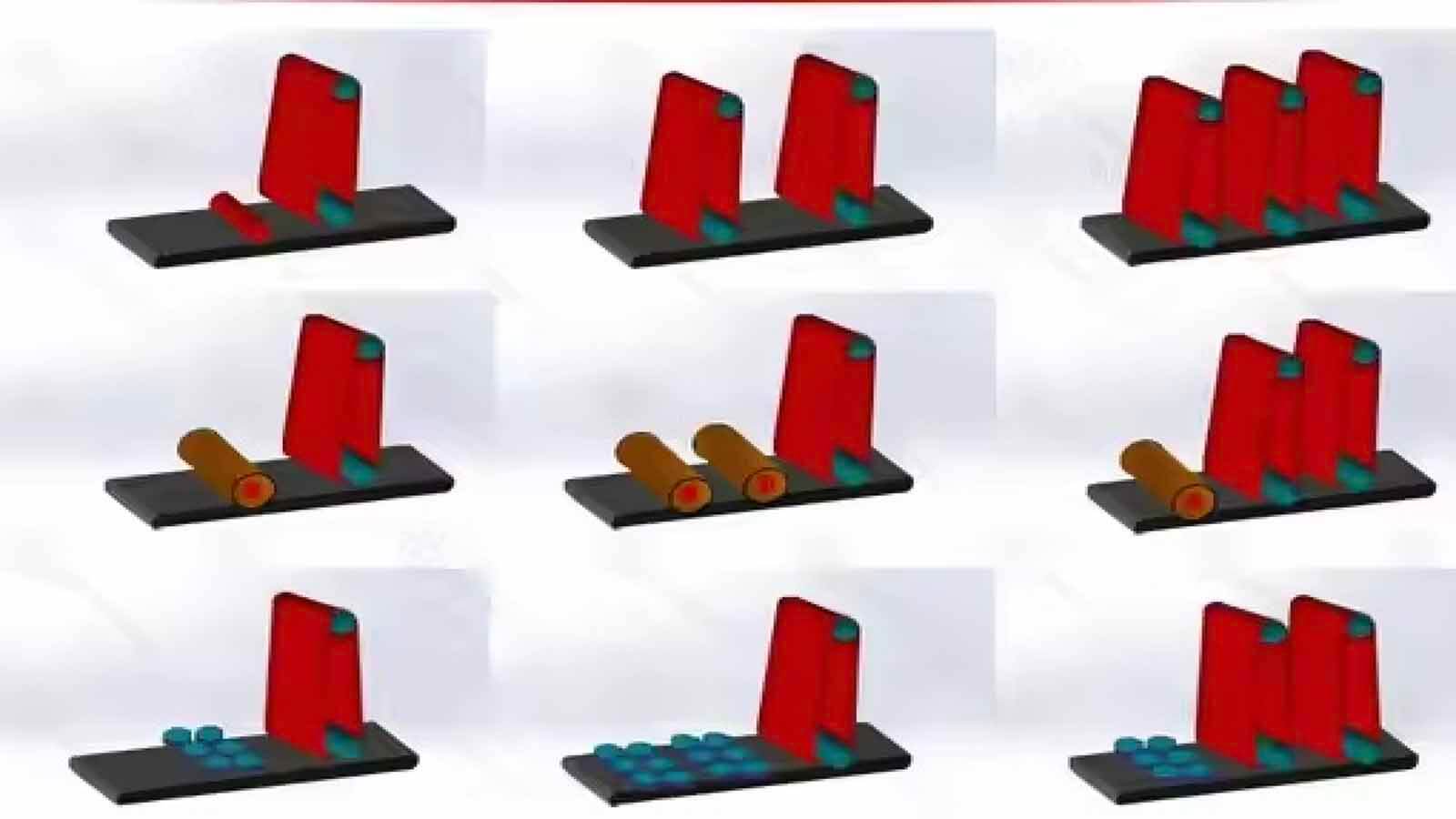

Set Up the 630 Metal Sander

- Select the Abrasive Belts:

- Use a coarse grit (e.g., 120-240) for removing imperfections.

- Gradually switch to finer grits (e.g., 600-800) for polishing.

- Adjust Machine Settings:

- Set the correct belt speed and pressure suitable for stainless steel.

- For wet machines, ensure the water or coolant system is active to minimize heat and improve surface quality.

Feed the Stainless Steel

- Position the Material: Place the stainless steel piece on the feeding conveyor.

- Align Properly: Ensure it is straight and centered to avoid uneven sanding.

- Feed Slowly: Allow the machine to sand uniformly without rushing the process

Start the Sanding Process

- Begin with Coarse Sanding: The initial passes should remove deep scratches or imperfections.

- Progress to Finer Grits: Gradually refine the surface by switching to finer abrasive belts.

Final Polishing

- For a mirror-like finish, use ultra-fine abrasives or polishing pads.

- Apply a polishing compound, if necessary, to achieve the desired shine.

Inspect the Surface

- Clean the Finished Piece: Wipe the surface with a soft cloth to remove any dust or residue.

- Check for Uniformity: Ensure the finish is even and free from visible scratches.

Tips for Best Results:

- Wear Protective Gear: Use gloves and goggles for safety.

- Use Wet Sanding: This reduces dust, prevents overheating, and extends the life of abrasive belts.

- Perform Regular Maintenance: Keep the 630 metal sander clean and replace worn belts promptly.

By following these steps, you can achieve a polished and professional finish on stainless steel using a 630 metal sanding machine.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao