Types of Industrial Sanders: When to Use Each

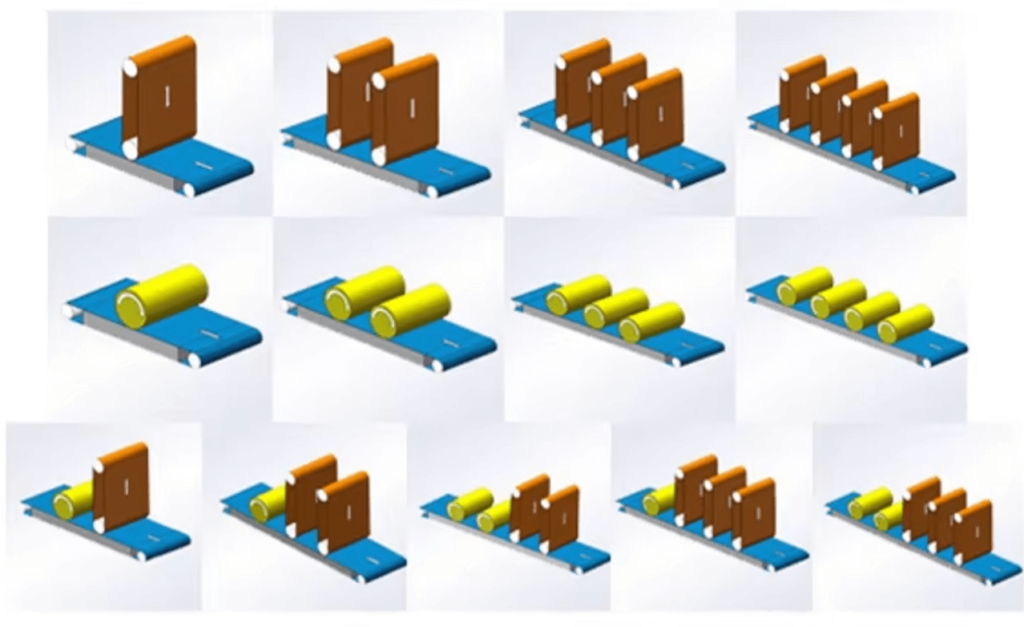

By simply switching the abrasive belt, this versatile machine can handle tasks such as slag and dross removal, grinding vertical burrs, and providing straight grain finishes, including the removal of mill scale.

Table of Contents

Belt Sanders: Versatile and Efficient

Belt sanders for stainless steel are among the most versatile sanding machines, offering excellent performance for heavy material removal and smoothing. Their continuous sanding belts make them ideal for tough materials such as stainless steel and iron.

Applications:

- Removing weld seams.

- Smoothing rough edges.

- Prepping surfaces for painting or coating.

Best for: Stainless steel, iron, and aluminum due to their durability and effectiveness in heavy-duty sanding tasks.

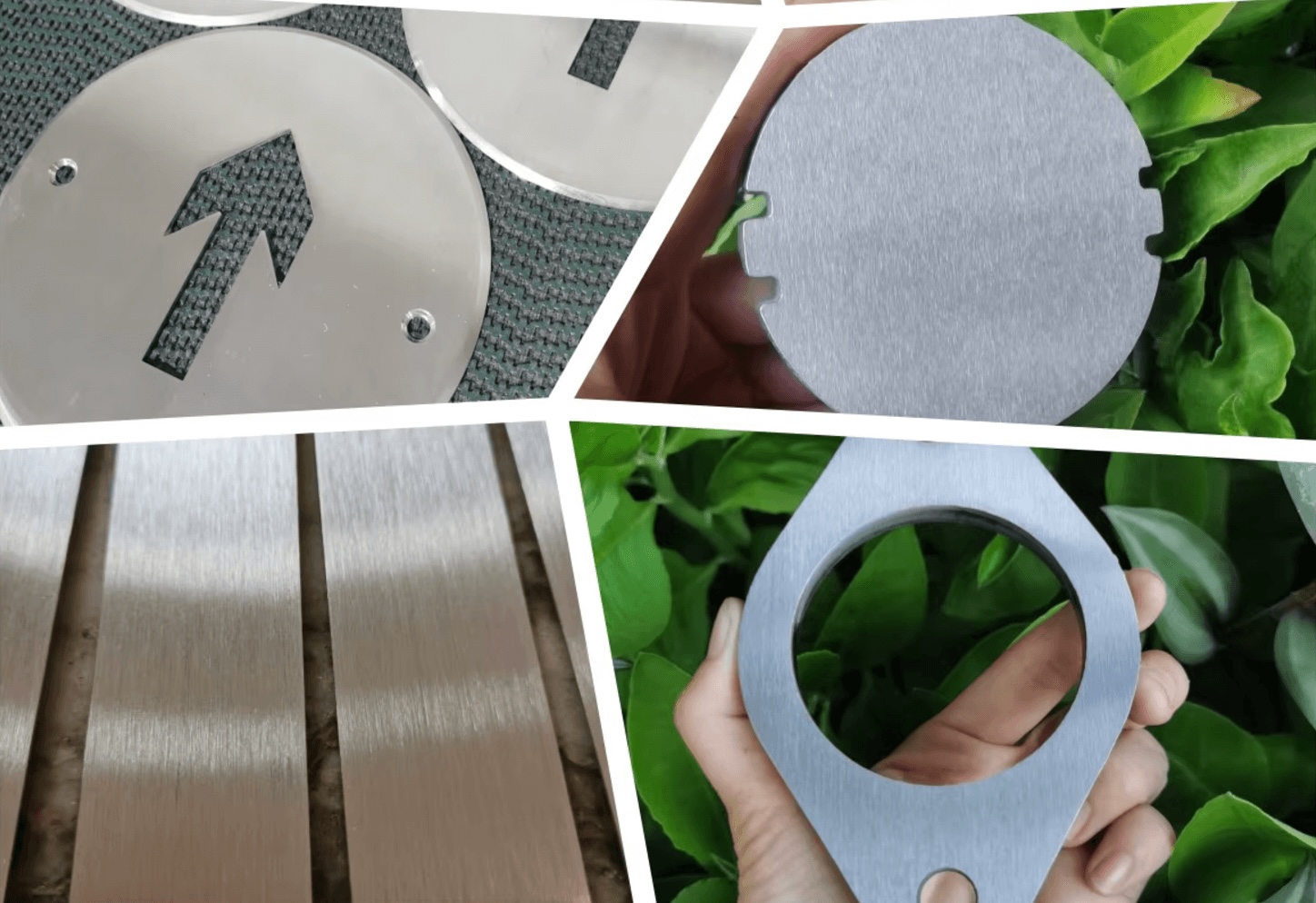

Disc Sanders: Precision and Control

Disc sanders for brass and other metals are ideal for precise work on smaller areas. These machines use circular sanding discs, which provide exceptional control for detailed sanding tasks.

Applications:

- Polishing curved surfaces.

- Refining intricate designs.

- Removing minor imperfections.

Best for: Soft metals like brass and aluminum where precision and care are paramount.

Orbital Sanders: Smooth and Uniform Finishes

Orbital sanders for aluminum are designed for delivering smooth and uniform finishes. Their circular motion ensures delicate sanding, making them perfect for thin or fragile metals.

Applications:

- Sanding decorative metalwork.

- Prepping surfaces for anodizing or plating.

- Achieving smooth finishes without gouging.

Best for: Aluminum, brass, and other soft metals requiring finesse and precision.

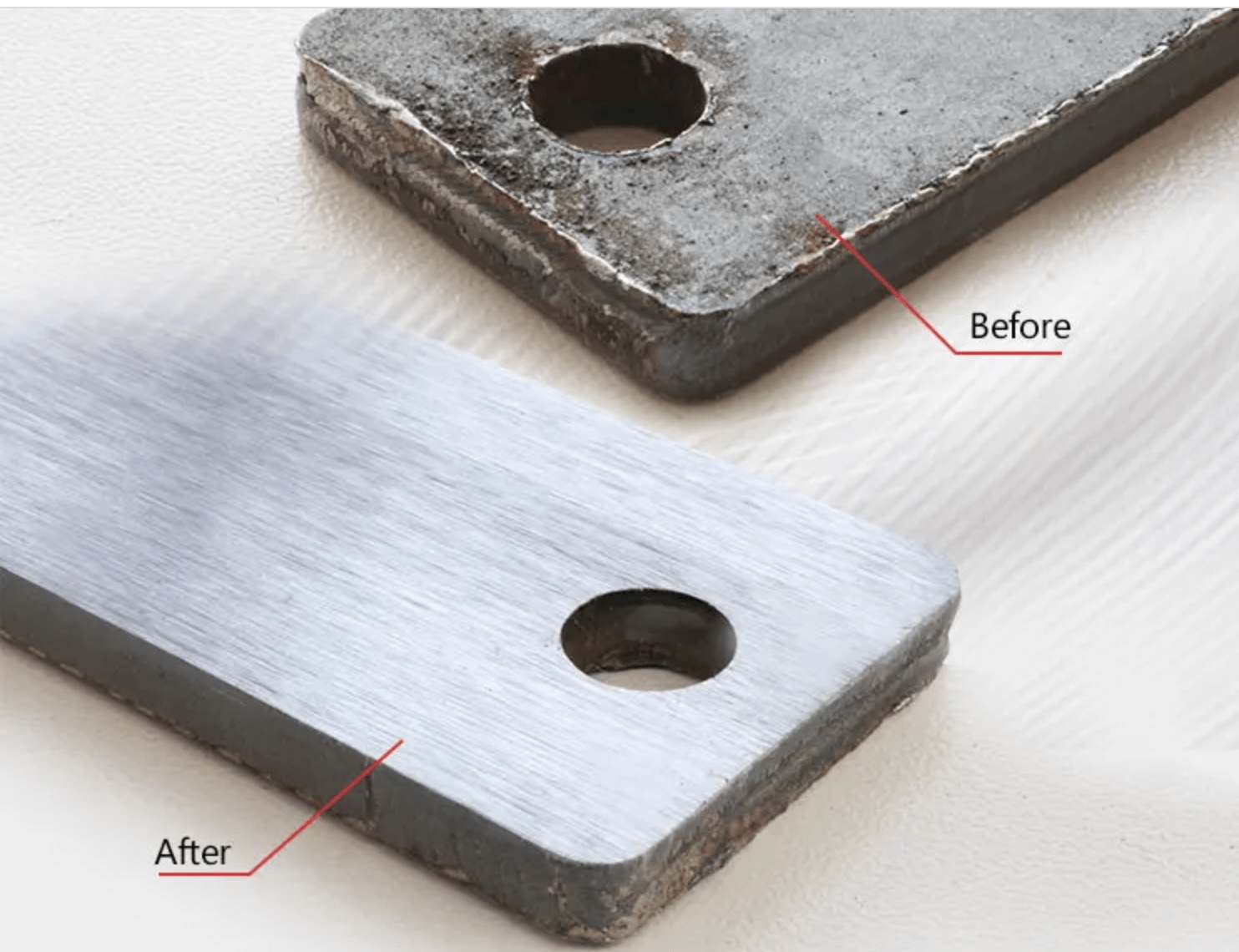

Wide Belt Sanders: High-Performance Sanding for Large Surfaces

Wide belt sanders are built for large-scale sanding projects, especially in industries dealing with stainless steel and iron sheets. These machines ensure consistent results over extensive surfaces.

Applications:

- Sanding metal sheets or plates.

- Removing oxides and scaling.

- Preparing surfaces for powder coating.

Best for: Stainless steel, iron, and aluminum sheets in high-volume production settings.

Grinding and Deburring Machines: Heavy-Duty Performance

When it comes to aggressive sanding and material removal, grinding and deburring machines are the top choice. These are ideal for industrial-grade work on iron and stainless steel.

Applications:

- Removing burrs and slag from cut edges.

- Grinding down heavy welds.

- Prepping metal surfaces for further processing.

Best for: Heavy-duty tasks involving stainless steel and iron.

Rotary Sanders: Flexible and Adaptable

Rotary sanders for intricate designs are excellent for tackling curved or uneven surfaces. Their spinning sanding pads adapt to complex shapes, making them indispensable for brass and aluminum workpieces.

Applications:

- Sanding decorative and functional parts.

- Polishing to a high shine.

- Refining edges and corners.

Best for: Aluminum, brass, and other metals requiring detailed sanding.

Vibratory Sanders: Gentle Yet Effective

Vibratory sanders for metal finishing are known for their gentle sanding action, making them perfect for delicate metals like brass and thin sheets of aluminum. Their oscillating motion prevents distortion while achieving smooth results.

Applications:

- Polishing thin metal parts.

- Smoothing sharp edges without distortion.

- Preparing for precision coating.

Best for: Aluminum and brass where controlled sanding is crucial.

Conclusion

Understanding the types of metal sanding machines and their specific applications is essential for achieving professional results. From belt sanders for stainless steel to orbital sanders for aluminum and disc sanders for brass, each tool offers unique capabilities. Wide belt sanders handle large surfaces, while grinding and deburring machines excel in heavy-duty tasks. For intricate designs, rotary sanders are invaluable, and vibratory sanders for metal finishing provide the finesse needed for delicate jobs.

Investing in the right industrial sander ensures efficiency, precision, and consistent quality in your metalworking processes. Whether working on robust stainless steel or crafting intricate brass pieces, selecting the appropriate sanding machine will elevate your results.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao