High-Performance Metal Sanding Machine with Advanced Features

Whether you’re working with stainless steel, aluminum, titanium, or copper, this versatile machine ensures that your metal surfaces are uniformly sanded, polished, and ready for subsequent processes. Equipped with advanced features like variable speed conveyors, motorized table lifts, and digital readouts, it is an essential asset for both small workshops and large-scale industrial operations. This article explores the key features and specifications of the metal sanding machine, highlighting its benefits for metal surface preparation and finishing.

Table of Contents

Features

- Motorized Table Lift: Equipped with a digital readout for precise adjustments.

- Variable Speed Conveyor: Offers flexibility to control sanding speed, improving efficiency for various tasks.

- Conveyor Forward & Reverse: Allows easy direction control for smoother material handling.

- Belt Safety Over Travel Switches: Ensures the machine automatically stops if the belt moves out of its intended travel range.

- Electronic Eye Belt Tracking: Features an advanced tracking system with a belt trimming lever to adjust for parallel belt misalignment during operation.

- 4-Jackscrew Table Support: Provides stable support to the sanding table, ensuring accuracy during use.

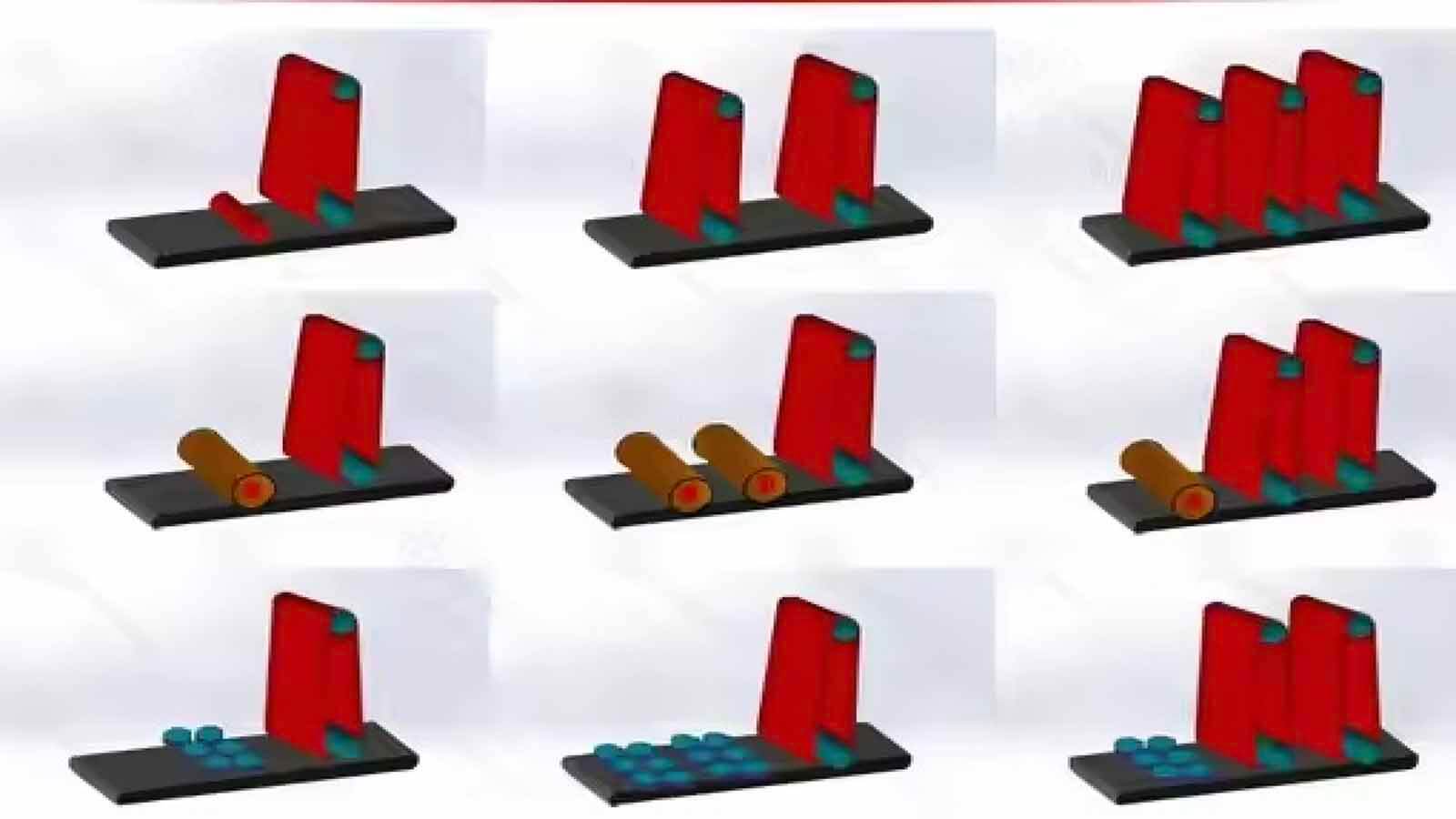

- Double Infeed & Outfeed Pinch Rolls: Equipped with protective guards to prevent any damage to materials.

- Conveyor Belt Tracking System: Ensures precise tracking for consistent sanding results.

- Safety System with Disc Brake: Air-operated disc brakes stop the sanding head in 3-5 seconds if air pressure is lost or an emergency stop is triggered.

- Table Height Digital Readout: Offers real-time height adjustments with accurate digital readings.

- Load Meter: Displays the motor load percentage, helping operators gauge performance.

- Belt Change Door with Safety Interlock: Electrically interlocked door for added safety during belt changes.

- Air Tensioning of Belt: Ensures precise tensioning and compensates for belt stretch, maintaining consistent performance.

- Quick Release Sanding Head Support: Facilitates fast and easy belt changes to maximize uptime.

- Dust Collection Hood: Equipped with a 4” outlet to keep work areas clean and safe by collecting dust at the abrasive head.

- Emergency Stops: Accessible from multiple points for operator safety.

- Noise Level: Maintains a low noise level, under 80 dba, for a quieter working environment.

Specification

- Standing Capacity: 24” x 6-1/8”

- Abrasive Belt Size: 25” x 60”

- Contact Roller Size: 8” Dia

- Passline Height: 31” – 37”

- Max Thickness Capacity: 6-1/8”

- Conveyor Drive Speeds: 8-40 FPM

- Infeed Conveyor Length: 20”

- Dust Collector Capacity: 1,100 CFM

- Electrics: 208/230V, 3-Phase

- Main Motor: 10 HP 230V 3PH

- Conveyor Motor: 1 HP 230V 3PH

- Table Lifting Motor: 1 HP 230V 3PH

- Net Weight (Approx.): 2,950 lbs

- Main Dimensions (LxWxH): 55” x 63” x 69”

Maintenance & Safety Recommendations

- Dust Collection: For optimal performance and to maintain the warranty, a high-quality dust collection system is highly recommended. If handling fire-hazardous materials such as aluminum, titanium, or magnesium, use a dust collection system that meets National Fire Protection Association (NFPA) standards.

- Wet Dust Collectors (Optional): These systems use water-filled tanks to trap grinding dust. The system uses a motor-driven fan to pull dust into the tank, where it settles and can be easily removed. The water level is automatically controlled when connected to a water supply, and units come equipped with an explosion relief door and sound silencer.

Conclusion

The metal sanding machine offers a robust and reliable solution for achieving high-quality finishes on metal surfaces. With advanced features such as adjustable conveyor speeds, a motorized table lift, and a dust collection system, it provides optimal performance and safety for a variety of metalworking applications. Whether you’re working in a small shop or a large industrial setting, this machine will improve your sanding processes, deliver superior results, and increase productivity. With optional wet dust collectors and customizable settings, it offers flexibility to suit your specific metalworking needs.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao