630mm Metal Sander Machine

- Model: R-R1300

- Customized: Accept

- Style: Wet/Dry

- Standard: Meet CE Standards in Terms of Quality & Safety

- Supplity: 360 Sets / Month Waiting for Sale In Stock

Description of 630mm Metal Sanders machine

Polishing coils and sheets is a high-value service offered by processing centers, with the right machinery being crucial for business success. OUYIGANG grinding and polishing machines make it easy to achieve a variety of finishes, including Matt, Hair-Line, Satin, No.4, and No.6. Our Aluminum Surface Polishing Machines are designed for processing the top surfaces of coils and sheets. As a leading provider of metal processing equipment, our machines dominate more than 70% of the Chinese market and are poised to meet global demand with their exceptional performance and cutting-edge technology.

These machines are primarily used for surface roughening of aluminum plates and other treatments to enhance surface adhesion.

Features of 630mm Metal Sanders machine

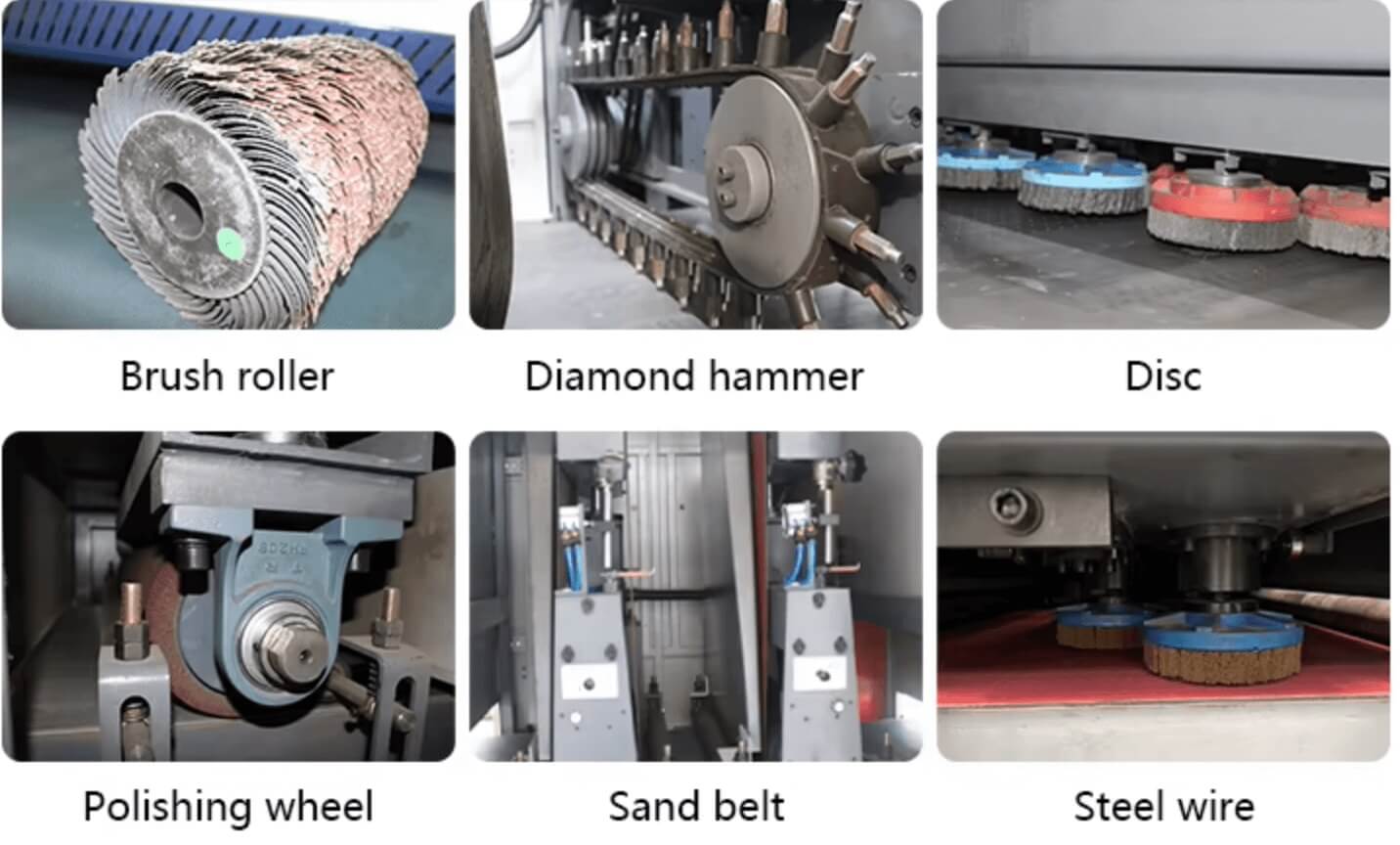

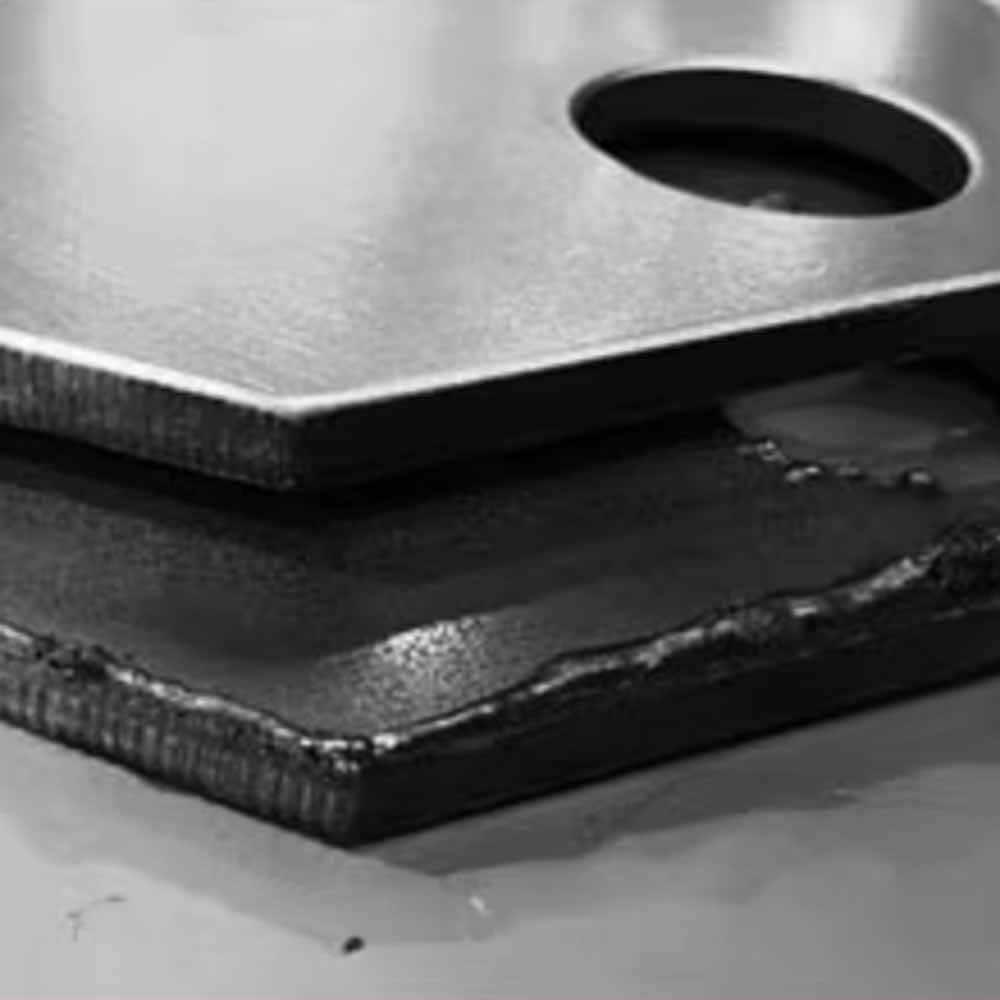

- Deburring and Edge Rounding: The machine provides flexible processing for both internal and external contours, ensuring that polished, brushed, or coated sheet metal surfaces remain intact and unaffected, preserving the finish and coating.

- Versatile Burr Removal: Ideal for removing burrs from holes in flat or nearly flat sheet metal parts processed by CNC punching, shearing, laser cutting, flame cutting, or plasma cutting, including slag removal.

- Improved Grinding Process: Replaces traditional filing, scraping, or manual grinding methods with electric or pneumatic tools, resulting in a more uniform surface finish. This process enhances safety, reduces labor costs, and boosts production efficiency.

- Precision Grinding Control: Allows visual adjustment of grinding and stroke parameters, ensuring only the edges and contours are ground without damaging the surface. This feature helps protect the coating and is suitable for materials like galvanized steel, coated aluminum, copper, and stainless steel.

- Advanced Adsorption Technology: The turbo vacuum adsorption system securely holds the workpiece during grinding, allowing for processing of both flat and shaped parts, even after bending. This feature improves processing efficiency while preventing vacuum system failure due to blockages. Additionally, the optional magnetic suction system reduces power consumption, promoting energy efficiency and cost savings.

- User-Friendly Control System: Equipped with a Delta PLC control system, the machine is easy to operate, offering convenient adjustments for grinding settings to achieve precise results.

- Energy-Saving Design: Selecting disk adsorption reduces power consumption, and the machine is compatible with standard consumables or can be equipped with custom imported sand wheels to enhance production efficiency and meet specific product requirements.

Parameters of 630mm Metal Sanders machine

| Parameter | unit | R630 | RR630 | RP630 | RRR630 | RRP630 | RRRP630 |

| Max working width | MM | 630 | 630 | 630 | 630 | 630 | 630 |

| Max working height | MM | 60 | 60 | 60 | 60 | 60 | 60 |

| Min working lengt | MM | 250 | 250 | 250 | 250 | 250 | 250 |

| First belt power | KW | 15 | 15 | 15 | 15 | 15 | 15 |

| Second belt power | KW | 11 | 11 | 11 | 11 | ||

| Third belt power | KW | 11 | 11 | 11*2 | |||

| Polishing wheel power | KW | 5.5 | 5.5 | ||||

| Rotating motor power | KW | ||||||

| Feeding power | KW | 1.5 | 1.5 | 1.5 | 2.2 | 2.2 | 2.2 |

| Lifting power | KW | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 | 0.37 |

| Swing motor power | KW | 1.5 | 1.5 | 1.5 | |||

| Vacuum motor power | KW | ||||||

| Machine size | M | 1.8*1.9* 2 | 2.1*1.9* 2 | 2.1*1.9* 2 | 2.4*1.9* 2 | 2.4*1.9* 2 | 2.7*1.9* 2 |

| Machine weight | KG | 1400 | 1600 | 1600 | 1800 | 1800 | 2000 |

| Belt size | MM | 1900*630 | 1900*630 | 1900*630 | 1900*630 | 1900*630 | 1900*630 |

| Water | tank and water pump for water mill | ||||||

| Dry | grinding plus dry dust collection | ||||||

| Conveying form | roller press feeding/permanent magnet adsorption feeding | ||||||

Details of 630mm Metal Sanders machine

Sand Rack

The front sand frame is the adjustable steel roller and the rear sand frame is the combined structure of the rubber roller mat, which is suitable for the constrant thickness and and fine polishing of various panels

Conveyor Belt

Working table for the thickend marble, conveyor belt for five layers of rubber material, not afraid of rain, not afraid of sun, long service life.

Internal Circuit

All the electrical parts are made of Chint electric applicances with stable performance. The machine internal wire connectrion is clear, no clutter.

Products details of 630mm Metal Sanders machine

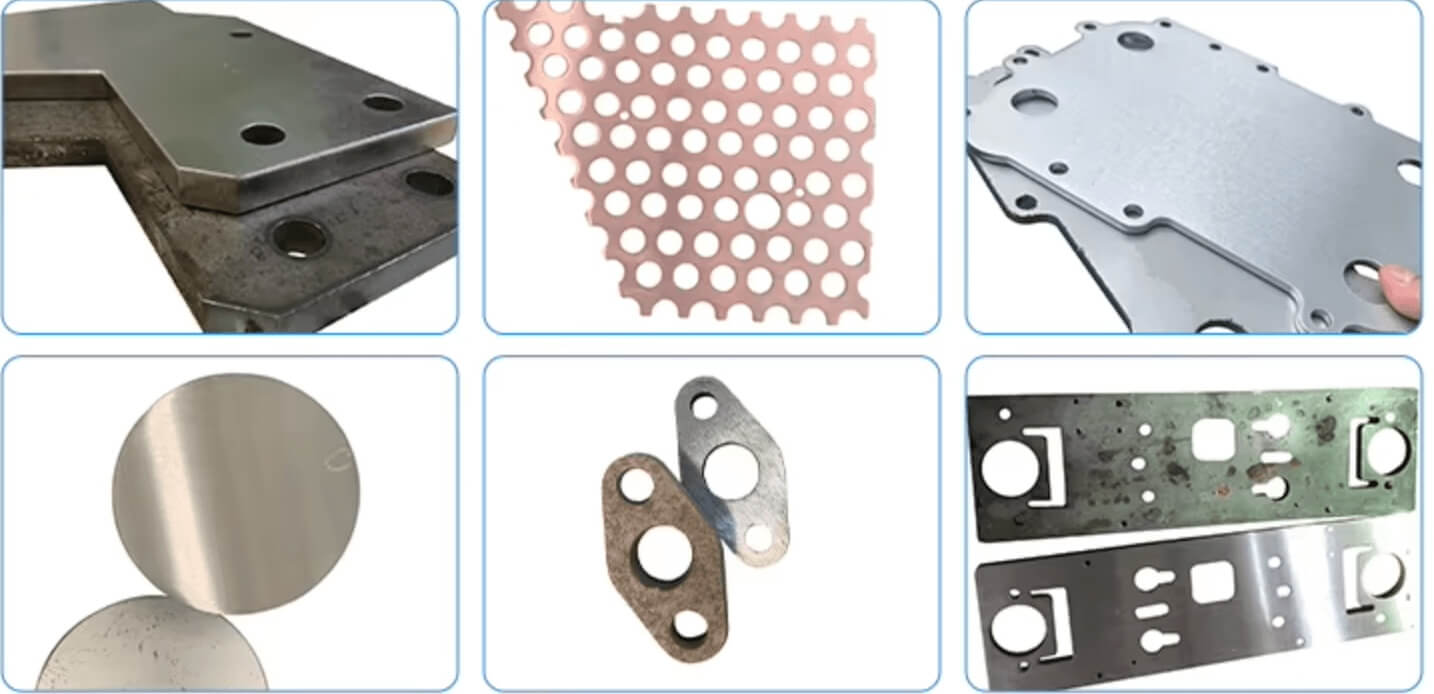

Polishing Brass Products

Stainless Steel Polishing

Special Shaped Iron Products

Presicion Grinding

Slag Off and Chanfer