Efficient Wide Belt Deburring Machines for Metal Plate Polishing

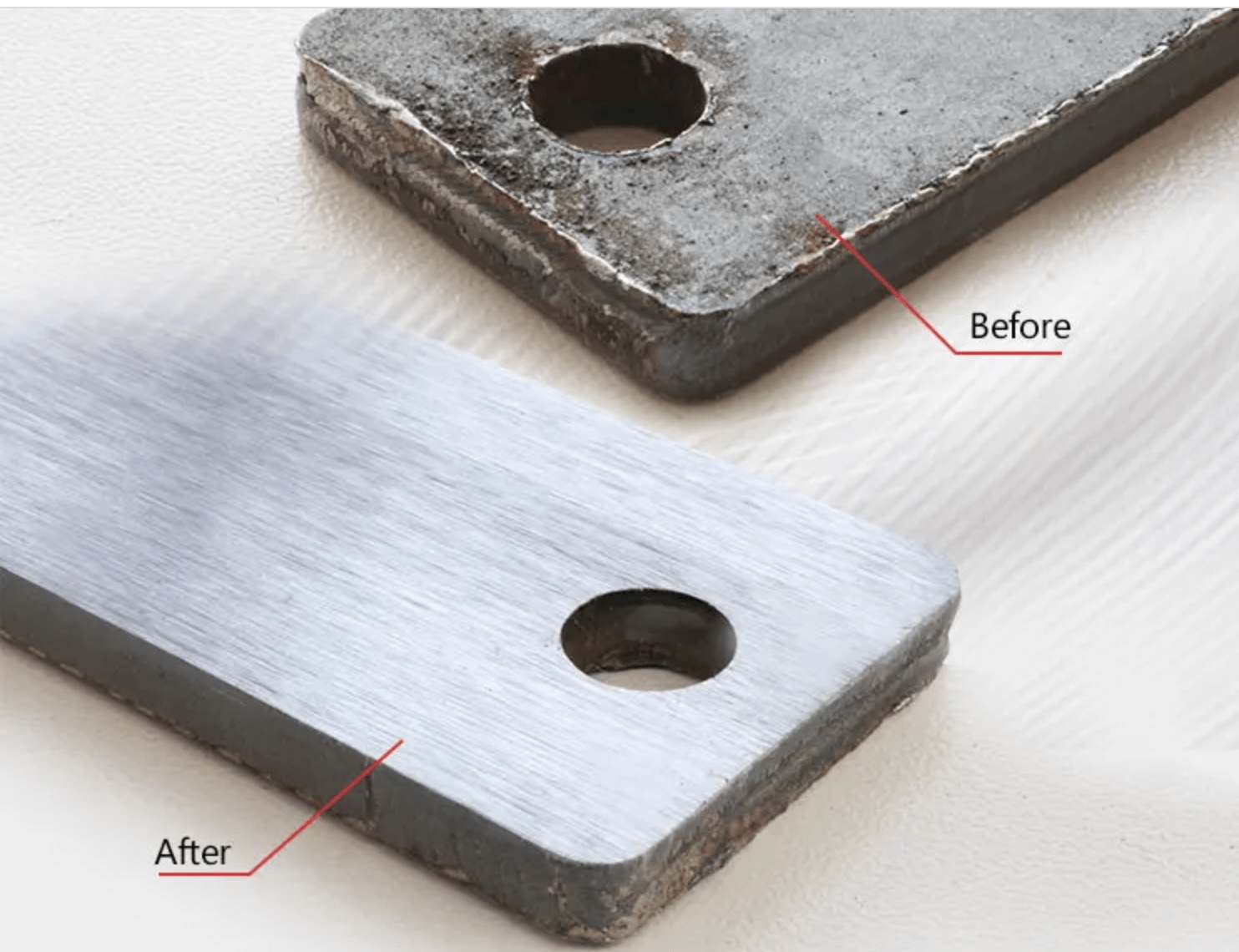

Uneven edges, burrs, and surface roughness can compromise the performance and appearance of metal products. A Wide Belt Deburring Machine is an essential tool for workshops aiming for precision, efficiency, and professional results.

Table of Contents

What is a Wide Belt Deburring Machine?

A Wide Belt Deburring Machine is designed to remove burrs, rust, oxidation, and rough edges from metal plates efficiently. Using abrasive belts, these machines ensure flat and smooth surfaces, making them ideal for preparation before coating, painting, or assembly.

Features of Sanding Deburring Machines

Modern Sanding Deburring Machines come with advanced features to improve productivity and surface quality:

- Adjustable Belt Speed: Enables precise control over sanding intensity for different metal types.

- High Durability: Heavy-duty construction ensures stability and long service life.

- Automated Feeding System: Consistent feed rate for uniform deburring and polishing.

- Dust Extraction System: Keeps the working environment clean and safe.

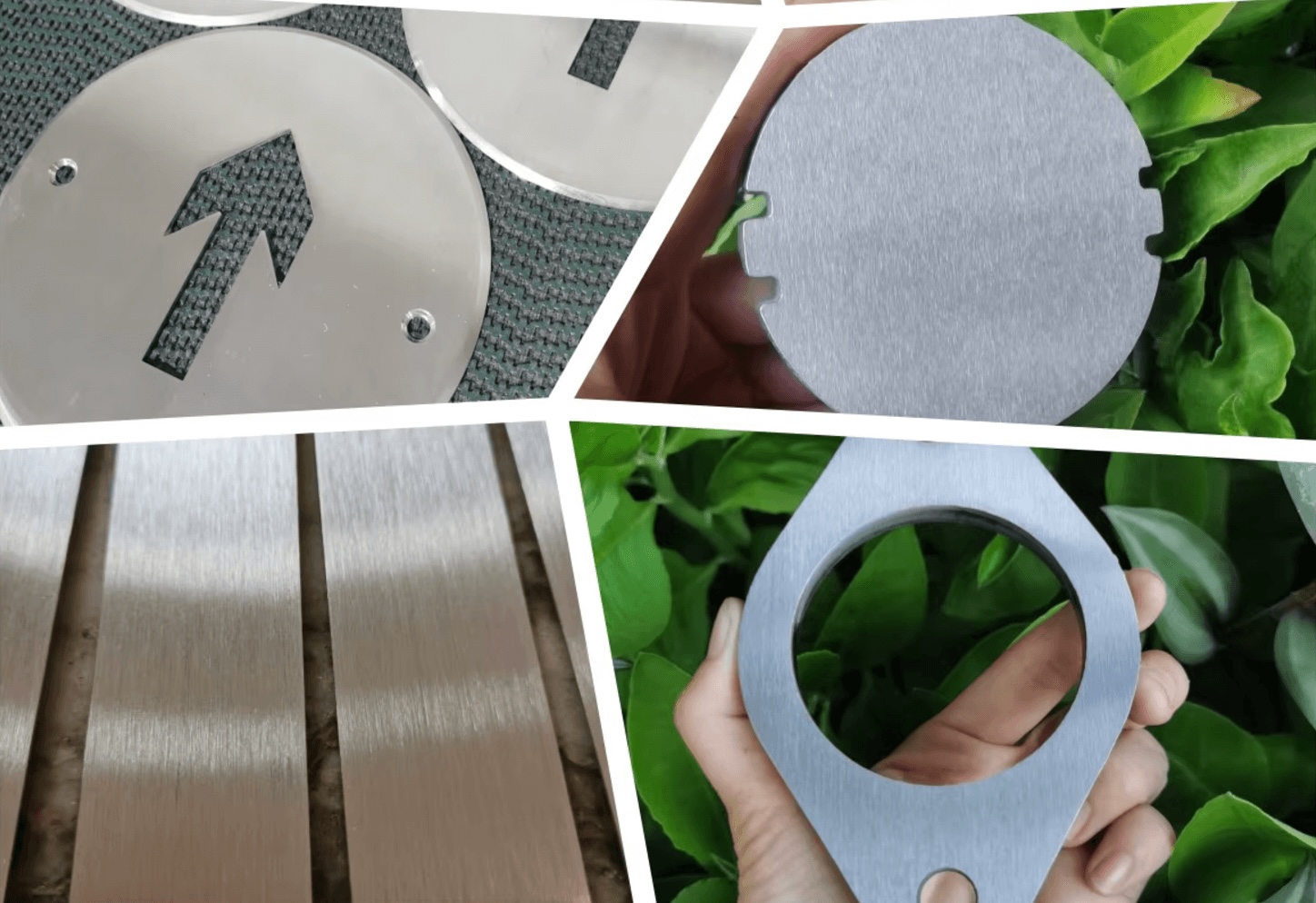

Applications of Metal Plate Deburring and Polishing Machines

These machines are versatile and widely used across industries:

- Metal Fabrication: Smooths edges and prepares metal plates for welding or coating.

- Automotive: Deburrs and polishes car components efficiently.

- Construction: Ensures structural metal parts are free of burrs for safe handling.

- Industrial Equipment: Polishes metal plates for machinery, tools, and appliances.

R-R1300 Wide Belt Deburring & Polishing Machine Specification

| Item | Specification |

|---|---|

| Model | R-R1300 |

| Max Working Width | 1300 mm |

| Min Working Length | 450 mm |

| Working Thickness | 2.5 – 110 mm |

| Sanding/Deburring Belt Size | 1330 x 2200 mm |

| Belt Speed | Frequency-controlled |

| Feeding Speed | 5 – 25 m/min |

| Total Motor Power | 63.05 kW |

| Conveyor Motor Power | 5.5 kW |

| Dust Extraction Capacity | 5000 m³/h |

| Compressed Air Consumption | 12 m³/h |

| Working Air Pressure | 0.6 MPa |

| Dimensions (L x W x H) | 2700 x 2100 x 2100 mm |

| Net Weight | Approx. 3200 kg |

| Key Features | Wide belt deburring, adjustable feeding speed, high-precision sanding and polishing, robust construction, dust collection system, user-friendly digital controls |

| Applications | Metal plate deburring, rust removal, flat polishing, surface preparation for coating, welding, or painting |

Benefits of Using a Wide Belt Deburring Machine

- Enhanced Surface Quality: Achieves uniform and polished finishes on metal surfaces.

- Time and Labor Saving: Automates repetitive sanding and polishing tasks.

- Versatility: Works on various metals including steel, aluminum, and stainless steel.

- Improved Safety: Reduces manual deburring, minimizing the risk of injury.

Choosing the Right Metalworking Equipment

When selecting a wide belt sander or CNC metal sander, consider:

- Material Type – Stainless steel, aluminum, carbon steel, brass.

- Required Finish – Brushed, matte, or mirror polish.

- Production Volume – High-volume lines benefit from CNC automation.

- Machine Size – Match the working width to your typical sheet dimensions.

Conclusion

Investing in a Wide Belt Deburring Machine or a Metal Plate Deburring and Polishing Machine is essential for any metalworking operation. These machines enhance productivity, ensure consistent surface quality, and save both time and labor. Whether for heavy-duty industrial applications or precision metal finishing, sanding deburring machines are key to achieving professional results.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao