Wide Belt Sander and CNC Metal Sander for Precision Metal Finishing

A Wide Belt Sander and CNC Metal Sander are key pieces of metalworking equipment that deliver precision, efficiency, and consistency in surface preparation. Whether for stainless steel finishing, deburring, or polishing, these machines are vital for industries where quality matters.

Table of Contents

Wide Belt Sander – The Power Behind Metal Surface Grinding

A Wide Belt Sander uses an abrasive belt to perform uniform metal surface grinding across large sheet sizes. It is ideal for preparing stainless steel, aluminum, and carbon steel surfaces for painting, coating, or assembly. These machines provide high material removal rates and consistent finishes, making them an essential sanding machine for metal production lines.

How Does It Work?

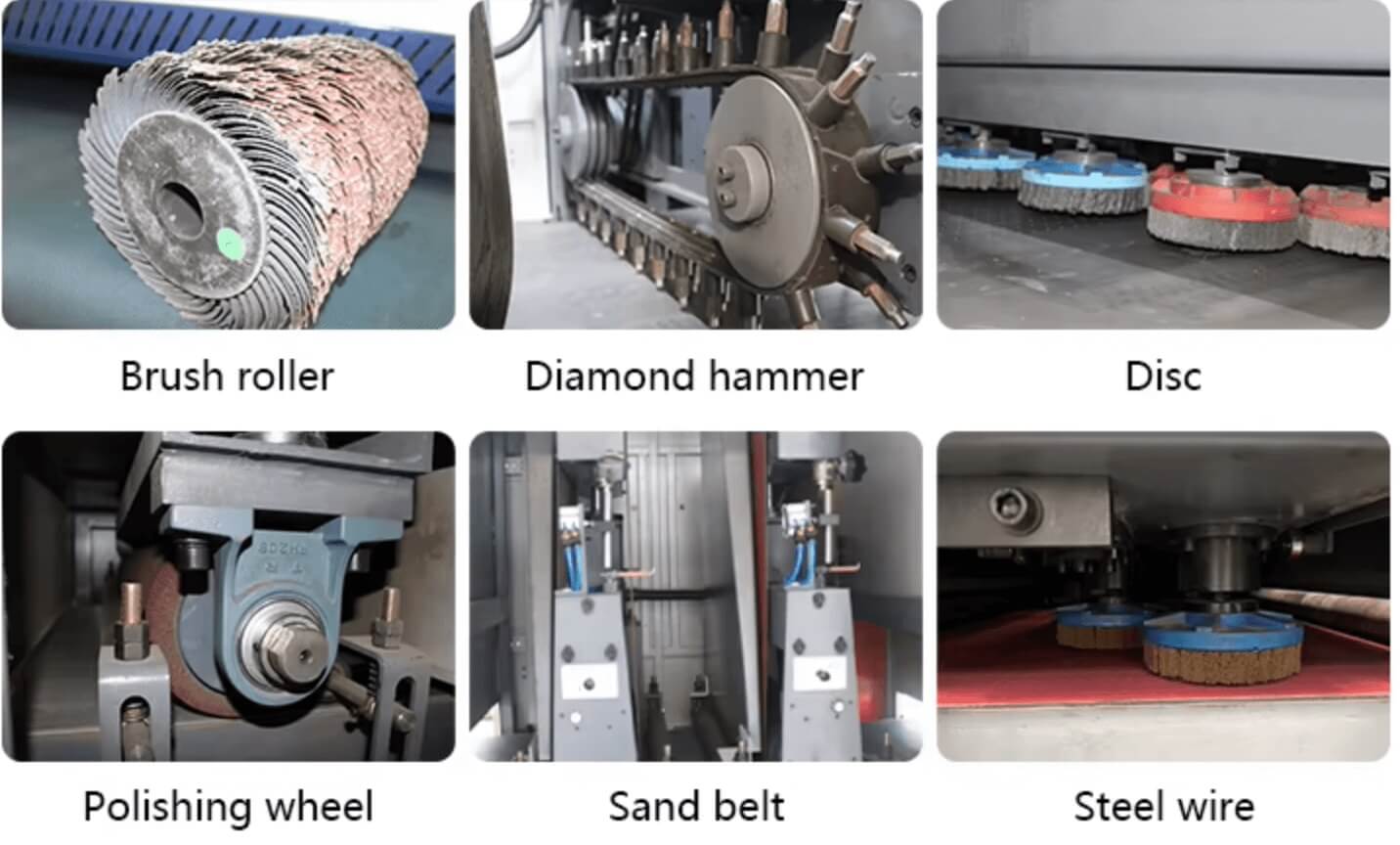

The machine operates by feeding metal parts through a series of rotating brushes. These brushes spin on axes perpendicular or parallel to the metal surface, depending on the machine design and application needs. As the parts pass through, the abrasive brushes “roll” over edges and surfaces, scraping away burrs and polishing the metal.

Many rolling brush deburring machines feature adjustable brush speed, pressure, and angles to accommodate different metal types, thicknesses, and burr sizes. This flexibility allows operators to fine-tune the process for optimal results.

CNC Metal Sander – Precision Meets Automation

For manufacturers requiring repeatable accuracy, a CNC Metal Sander automates the sanding process using programmable settings. This ensures exact surface profiles, reduces human error, and speeds up production. CNC-controlled machines are especially useful for complex parts where precision finishing is crucial.

Stainless Steel Finishing Machine – For Decorative and Functional Results

A stainless steel finishing machine can produce a variety of surface textures—from brushed patterns to mirror finishes. This is particularly valuable in industries like kitchen equipment manufacturing, architectural cladding, and high-end furniture.

Deburring Machine – Essential for Safety and Quality

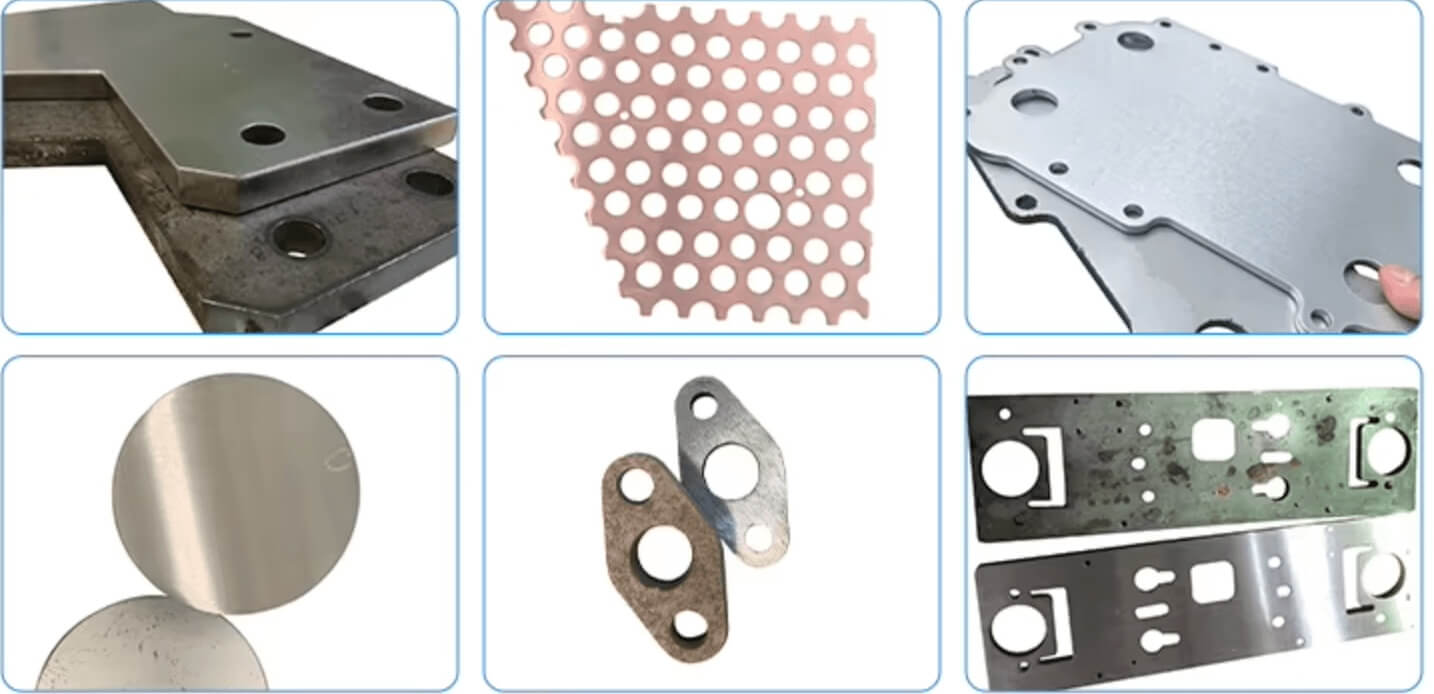

Metal edges often have burrs after laser cutting, plasma cutting, or punching. A deburring machine quickly removes these sharp edges, improving safety, assembly fit, and final product quality.

Sheet Metal Polishing Machine – Shiny, Smooth, and Ready for Use

For projects where appearance is critical, a sheet metal polishing machine delivers a smooth, reflective finish. This type of industrial metal sander can process everything from thin decorative panels to thick structural plates.

Metal Sander Machine Specification Table

| Parameter | Specification |

|---|---|

| Model | RR-R1300 |

| Working Width | 1300 mm |

| Working Thickness | 0.5 – 120 mm |

| Abrasive Belt Size | 1330 × 2200 mm |

| Feeding Speed | 5 – 30 m/min (adjustable) |

| Main Motor Power | 37 kW |

| Feeding Motor Power | 2.2 kW |

| Lift Motor Power | 0.55 kW |

| Vacuum Pump Power | 5.5 kW |

| Total Power | 45 kW |

| Abrasive Belt Type | Wide Belt + Rotary Brush |

| Control System | PLC with Touch Screen |

| Dust Collection Port | 150 mm × 3 |

| Machine Dimensions | 2620 × 2100 × 2100 mm |

| Machine Weight | 4800 kg |

Applications of Industrial Metal Sanders

- Automotive Industry – Preparing car panels for painting or coating.

- Architecture – Producing decorative stainless steel panels.

- Shipbuilding – Grinding and polishing marine-grade metals.

- Fabrication Shops – Deburring and smoothing sheet metal components.

Choosing the Right Metalworking Equipment

When selecting a wide belt sander or CNC metal sander, consider:

- Material Type – Stainless steel, aluminum, carbon steel, brass.

- Required Finish – Brushed, matte, or mirror polish.

- Production Volume – High-volume lines benefit from CNC automation.

- Machine Size – Match the working width to your typical sheet dimensions.

Conclusion

Whether you need a sanding machine for metal, a deburring machine, or a sheet metal polishing machine, investing in the right metalworking equipment ensures quality, efficiency, and long-term reliability. A wide belt sander or CNC metal sander is not just a tool—it’s the key to achieving professional, repeatable results in metal surface grinding and finishing.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao