High-Quality Sheet Metal Debur Machine for Precision Finishing

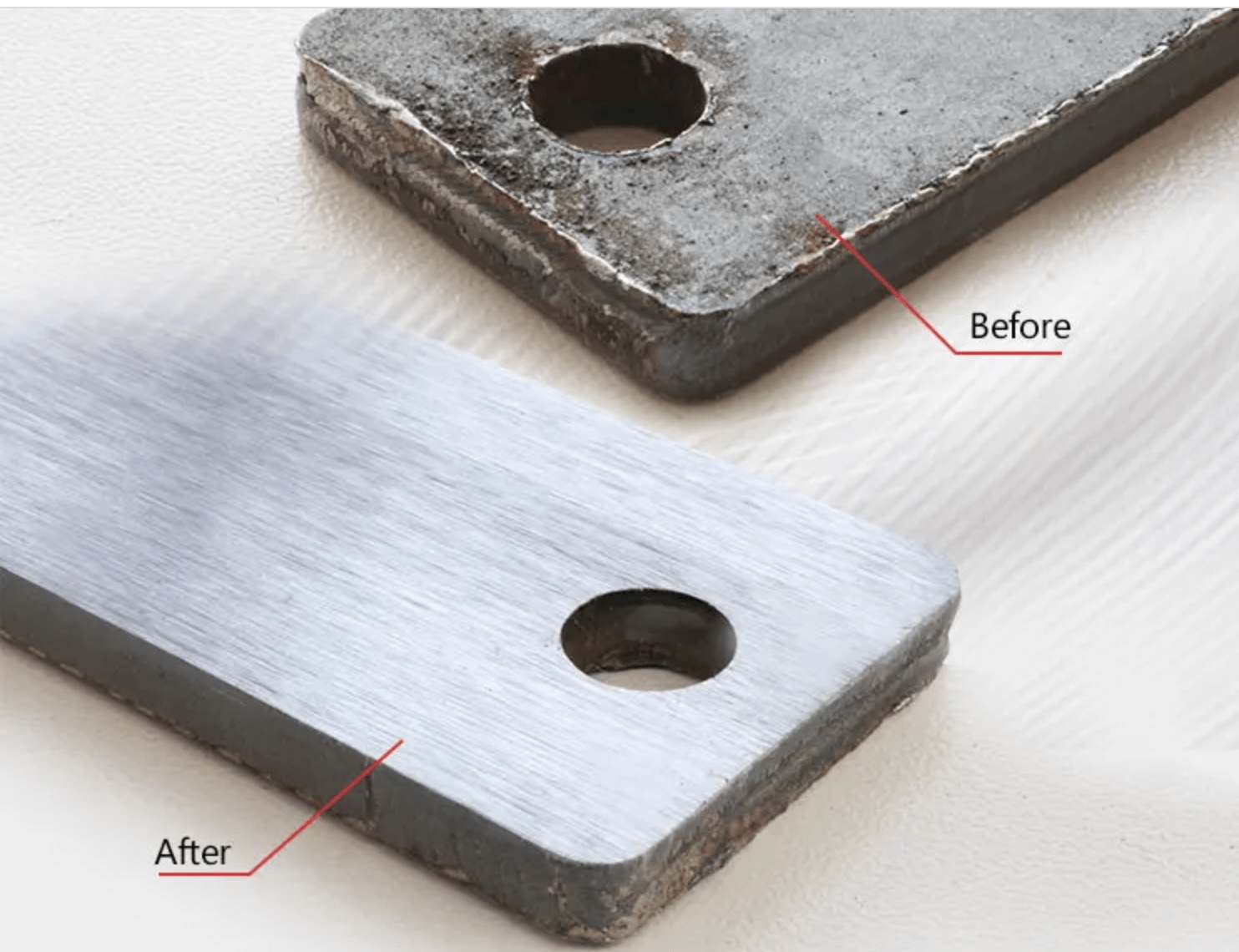

Whether you’re producing enclosures, brackets, or complex assemblies, removing sharp edges and burrs from cut or punched sheet metal is essential. Investing in a reliable sheet metal deburring machine ensures better fitment, safer handling, and an enhanced product finish.

Table of Contents

What Is a Sheet Metal Debur Machine?

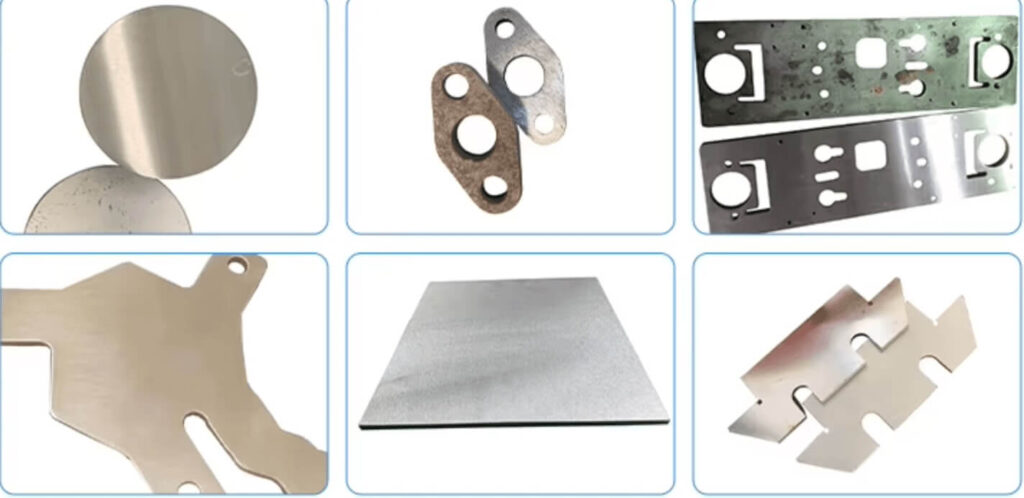

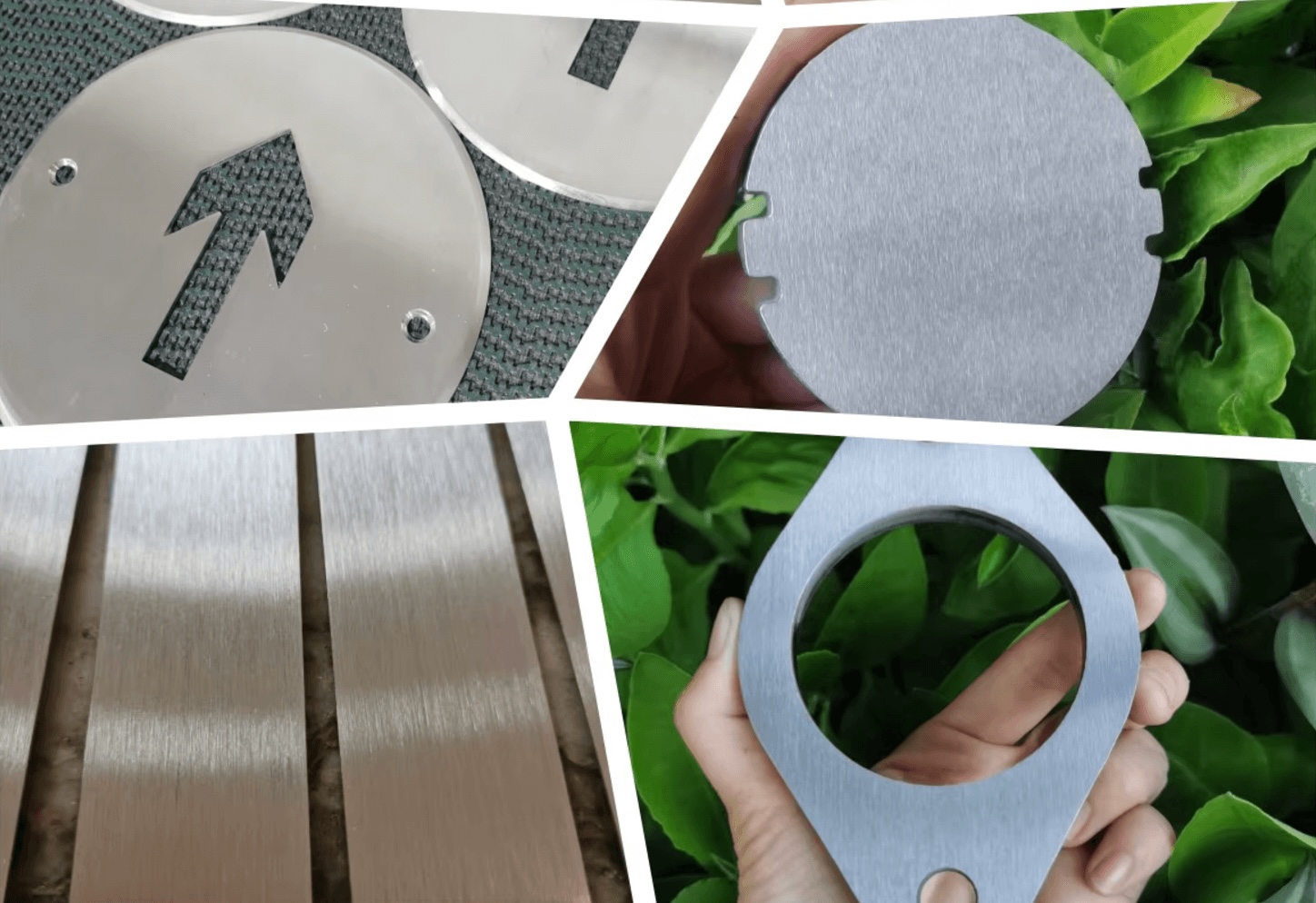

A sheet metal debur machine is specialized equipment designed to remove burrs, sharp edges, slag, and oxide layers left behind during laser cutting, punching, or shearing processes. These machines typically use abrasive belts, rotating brushes, or combination heads to perform edge rounding, deburring, and surface finishing in one pass.

One of the most advanced variants is the sheet metal debur machine jet, which uses high-speed abrasive flow or air-assisted jets to target precise areas. This method is especially effective for complex cut-outs and precision parts, reducing manual labor and increasing consistency.

Trusted Sheet Metal Deburring Machine Manufacturers in India

India has become a competitive hub for engineering solutions, including sheet metal deburring machine manufacturers who deliver industrial-grade performance at affordable costs. These manufacturers offer both standard and customized solutions to match the production needs of various sectors such as aerospace, electronics, furniture, HVAC, and metal fabrication.

As a leading sheet metal deburring machine exporter, many Indian companies now supply equipment worldwide, gaining recognition for their innovation, reliability, and cost-efficiency.

Key Features to Look for in a Sheet Metal Deburring Machine

- Automatic Feeding System: Increases processing speed and reduces operator fatigue.

- Dual-Sided Deburring: Simultaneously finishes both top and bottom surfaces.

- Rotary Brush + Sanding Belt: Ensures edge rounding and surface smoothing.

- Programmable Settings: Offers precision control for different material types and thicknesses.

- Compact Design: Saves floor space while maintaining high throughput.

Technical Specifications

| Item | Details |

|---|---|

| Model Name | MS Series Sheet Metal Deburring Machine |

| Deburring Method | Abrasive Belt + Rotary Brush |

| Material Compatibility | Steel, Stainless Steel, Aluminum, Copper |

| Max Working Width | 600 mm / 1000 mm / 1300 mm (customizable) |

| Max Workpiece Thickness | 0.5 – 100 mm |

| Minimum Workpiece Size | 50 mm × 50 mm |

| Deburring Sides | Top only / Top and Bottom (dual-sided) |

| Feeding Speed | 0.5 – 8 m/min (adjustable) |

| Abrasive Belt Size | 1900 × 190 mm |

| Brush Diameter | 300 mm |

| Dust Extraction Port | Yes (with optional dust collector) |

| Control System | Touch Screen PLC / Manual Panel (optional) |

| Power Supply | 380V / 50Hz / 3 Phase (customizable) |

| Total Power | 10 kW – 25 kW (model-dependent) |

| Dimensions (L×W×H) | 2300 × 1400 × 1800 mm (standard model) |

| Machine Weight | 1500 – 2500 kg (depending on model) |

| Noise Level | ≤ 75 dB |

| Optional Features | Vacuum conveyor, magnetic table, water mist system |

| Application | Laser-cut parts, punched sheet metal, plasma-cut parts, etc. |

| Country of Origin | Made in China |

| Export Markets | Europe, Middle East, Southeast Asia, Americas |

Conclusion: Your Complete Metal Finishing Solution

Choosing the right sheet metal deburring machine enhances your production quality and efficiency. Whether you’re sourcing a machine domestically or from a trusted sheet metal deburring machine exporter, look for features that match your specific needs and material types. As sheet metal deburring machine manufacturers in India continue to innovate and expand globally, industries around the world benefit from cost-effective, high-performance finishing solutions.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao