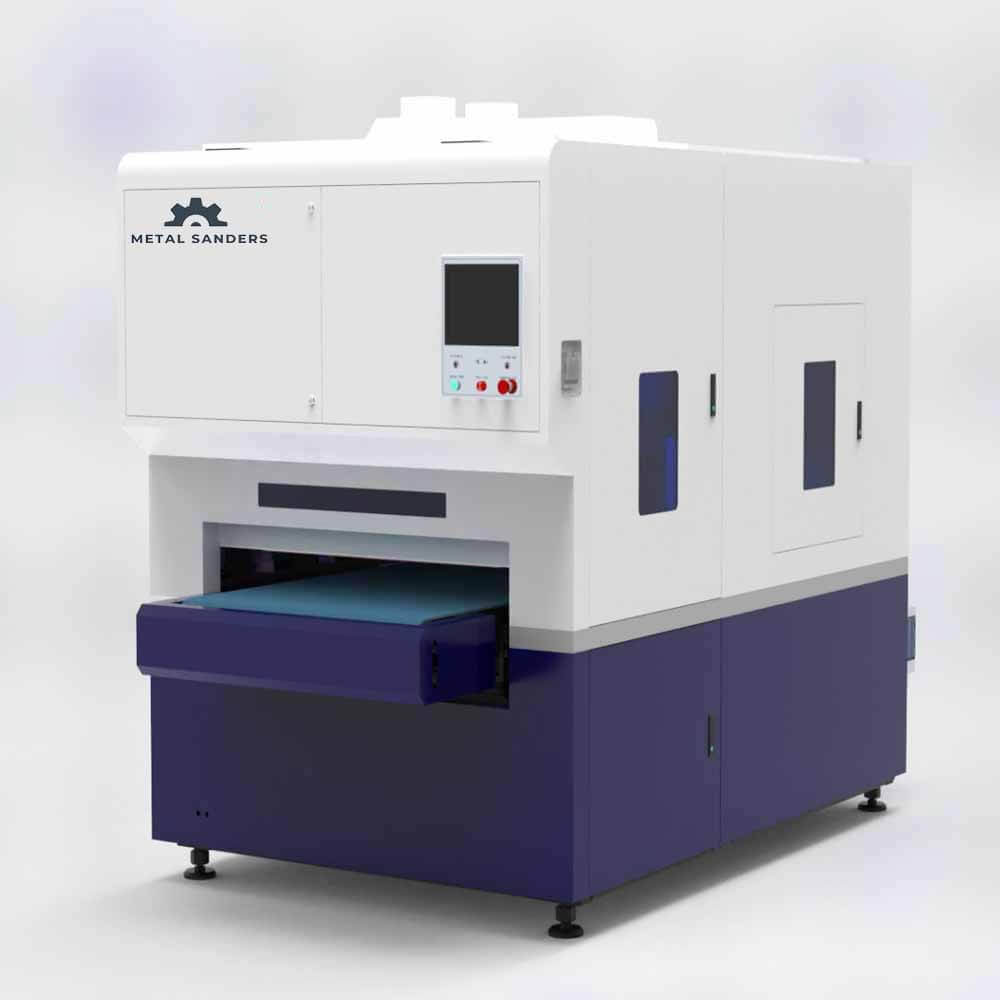

Find the Right Sheet Metal Deburring Machines for Flat Metal Finishing

Whether you’re producing stainless steel panels, aluminum enclosures, or carbon steel plates, a flat metal sheet deburring machine is essential for eliminating sharp edges, burrs, and oxidation layers.

Choosing the right machine—and the right manufacturer—can dramatically improve your production efficiency, surface quality, and worker safety. In this article, we’ll guide you through the benefits of flat metal deburring systems and how to select a trusted flat metal sheet deburring machine factory.

Table of Contents

What Is a Flat Metal Sheet Deburring Machine?

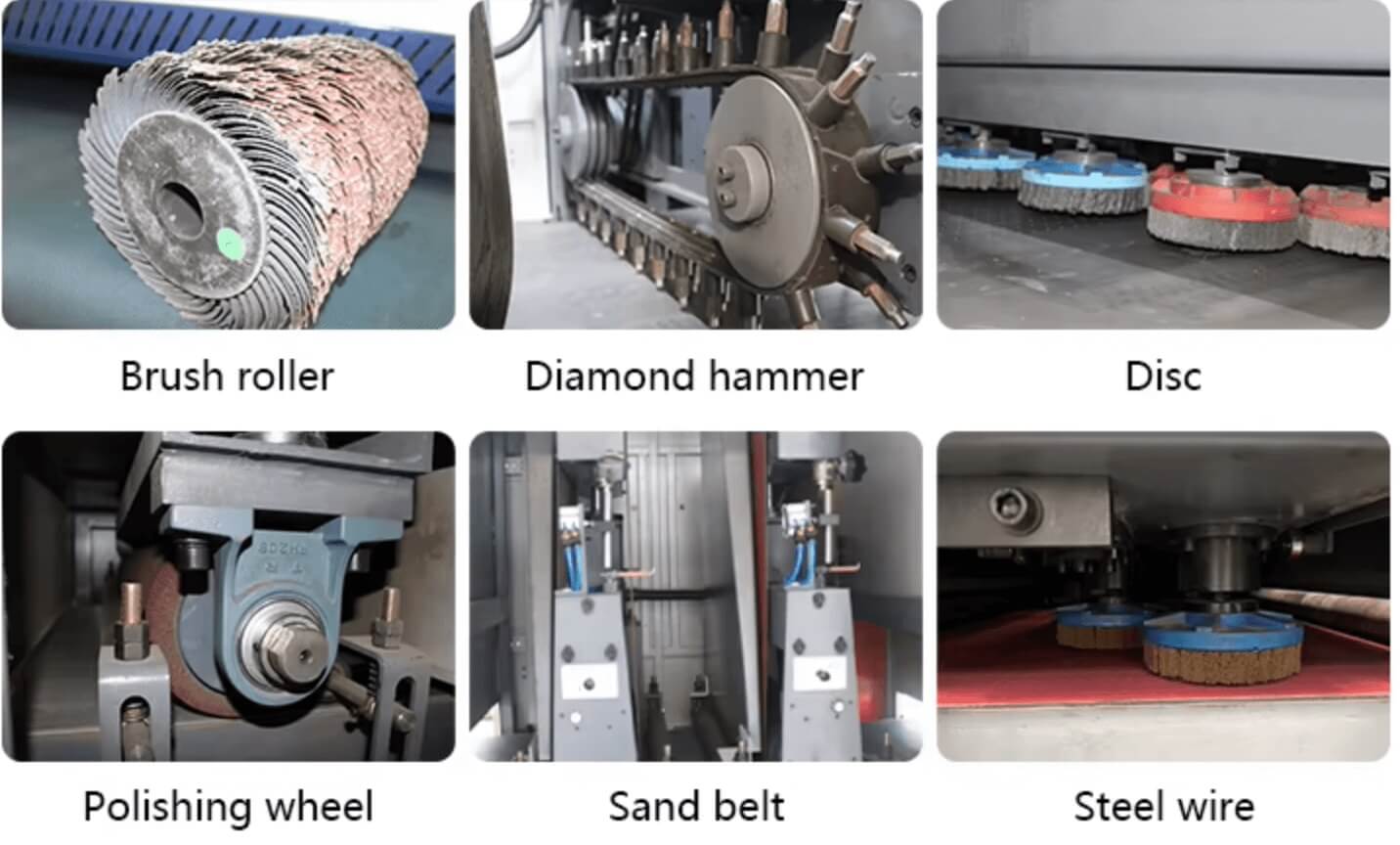

A flat metal sheet deburring machine is an industrial tool used to smooth and round the edges of metal sheets after cutting or punching. These machines often combine wide-belt grinding, rotating brushes, and polishing systems to process both edges and flat surfaces in one pass.

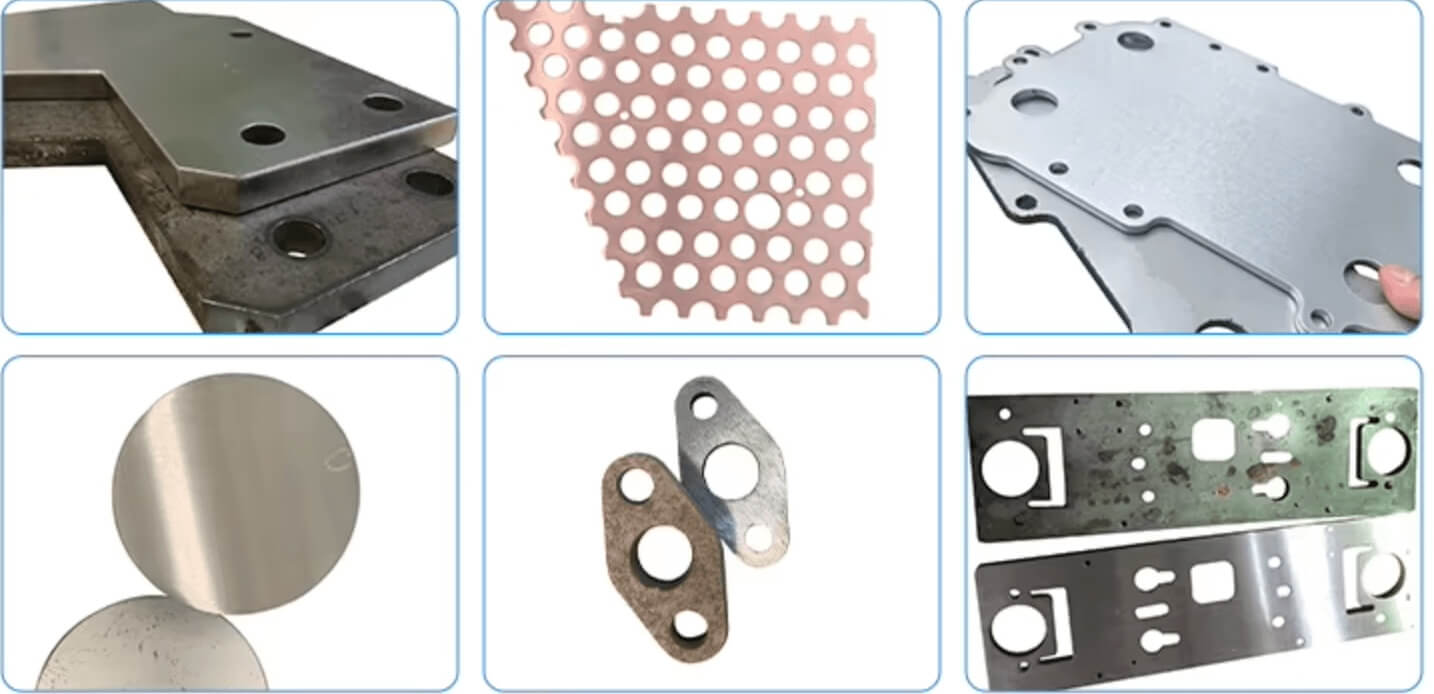

Modern deburring machines are designed to handle high volumes of sheet metal parts with varying thicknesses and materials, including:

- Stainless steel

- Aluminum

- Mild steel

- Galvanized sheet

- Brass and copper

Why You Should Find a Reliable Flat Metal Sheet Deburring Machine Factory

Not all machines are created equal. Partnering with a reliable flat metal sheet deburring machine factory ensures:

- Quality Engineering & Construction – Industrial-grade structure and components

- Customizable Configurations – Adjusted to your material types, sheet sizes, and burr severity

- CNC Control & Automation – Easy operation, minimal training required

- After-Sales Service & Support – Fast spare parts, technical help, and machine upgrades

Factories with experience in global metal processing markets can offer export-ready, CE-certified machines tailored for your production line.

Features to Look for When You Find Sheet Metal Deburring Machines

- Dual-Side Deburring – Process both top and bottom edges in a single pass

- Vacuum or Magnetic Table – For stable handling of small/thin parts

- Dry or Wet Deburring Modes – Choose based on dust management and part cooling needs

- Touchscreen Control – CNC interface for repeatable, programmable settings

- Edge Rounding + Surface Finishing – Combined functions save space and labor

Applications of Flat Metal Sheet Deburring Machines

These machines are widely used in:

- Laser cutting and punching workshops

- Electrical enclosure and panel factories

- Elevator and kitchen equipment production

- Automotive and aerospace metal part processing

- General sheet metal fabrication plants

Whether for mass production or high-precision parts, a high-quality flat metal sheet deburring machine ensures safety, quality, and efficiency.

Technical Specification

| Feature | Specification |

|---|---|

| Working Width | 600 / 1000 / 1300 mm |

| Material Thickness | 0.5mm – 100mm |

| Deburring Method | Brush + Belt + Optional Roller |

| Control System | PLC or Touchscreen CNC |

| Conveyor Speed | 0 – 10 m/min (adjustable) |

| Operation Mode | Dry / Wet |

| Dust Collection | Integrated / Optional |

Conclusion

If you’re ready to find sheet metal deburring machines that match your production needs, now is the time to invest in a professional-grade solution. A high-performance flat metal sheet deburring machine improves product quality, shortens processing time, and reduces labor intensity.

When sourcing, always choose a trusted flat metal sheet deburring machine factory that offers customization, technical support, and proven results in the global metal fabrication industry.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao