Why a Deburring Machine is Essential for Sheet Metal Processing

That’s why using a deburring machine in sheet metal manufacturing has become an industry standard. Whether you’re making enclosures, brackets, or custom parts, a reliable deburring and polishing machine significantly improves your workflow.

In this article, we explore the benefits of deburring and polishing machines in sheet metal making, and why they’re a must-have for professional manufacturers.

Table of Contents

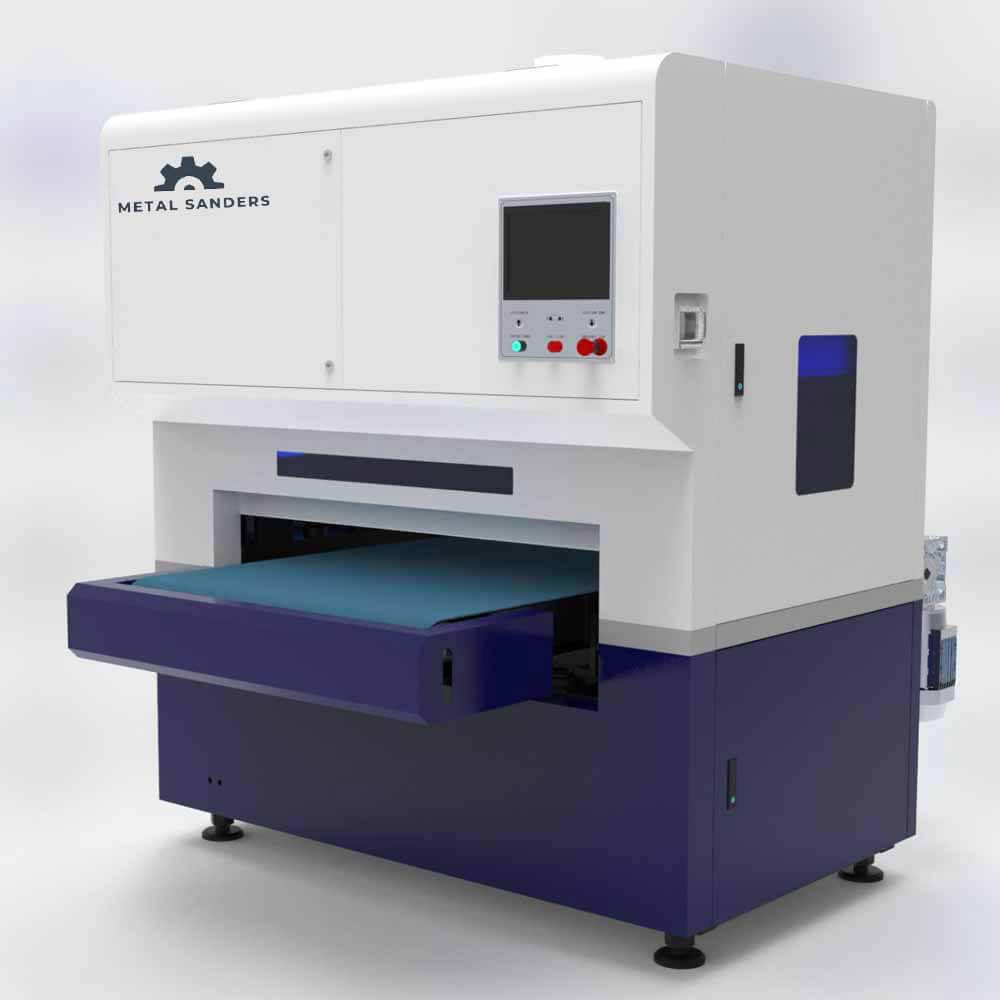

What Is a Deburring Machine for Sheet Metal?

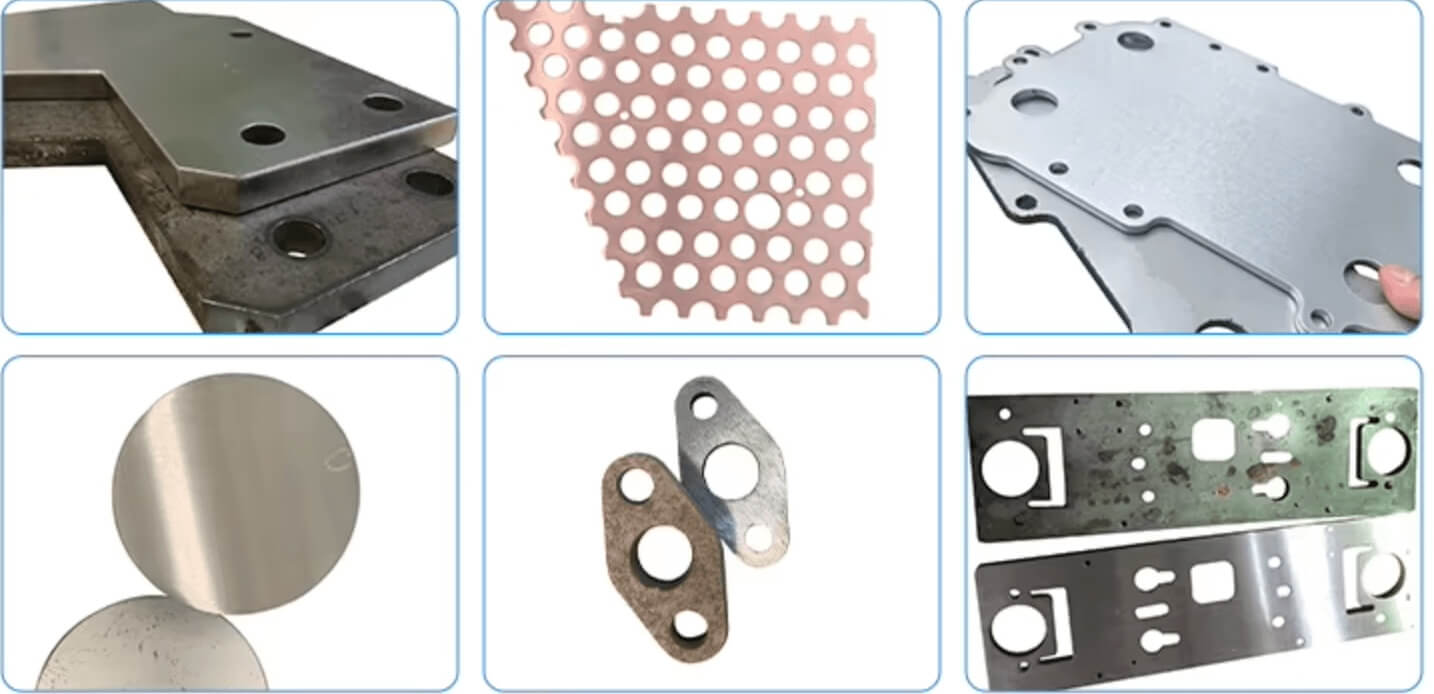

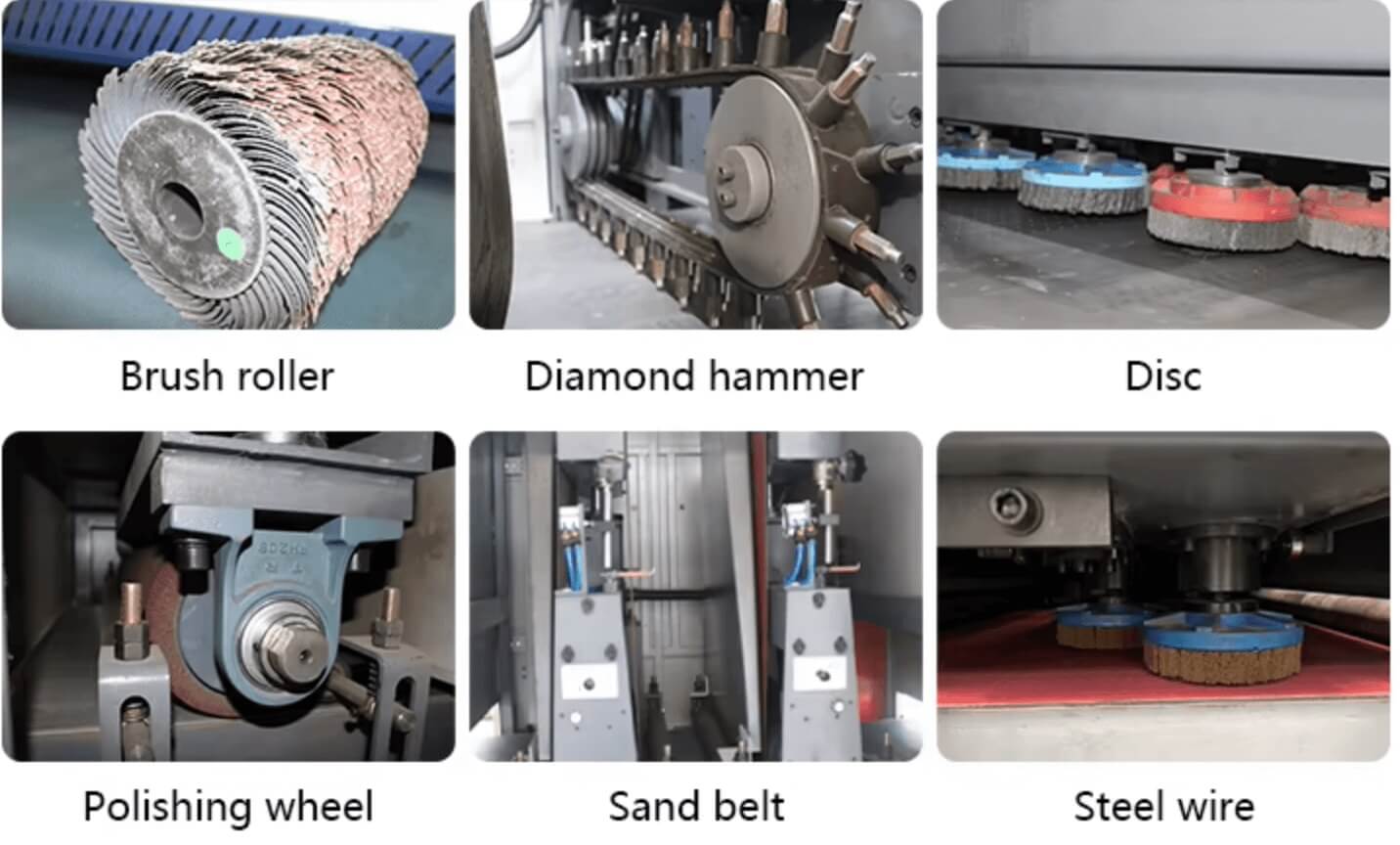

A deburring machine for sheet metal is a specialized industrial tool designed to remove burrs, sharp edges, and surface imperfections that result from laser cutting, punching, or shearing. Often integrated with polishing or brushing units, these machines help produce clean, smooth, and safe parts for downstream processing like painting, welding, or assembly.

Key Benefits of Deburring and Polishing Machines in Sheet Metal Making

1. Improved Safety and Handling

Burrs and sharp edges are safety hazards. A deburring machine sheet metal solution eliminates those dangerous edges, protecting workers during handling and reducing the risk of injury in final use.

2. Enhanced Surface Quality

Polishing units integrated into the machine provide a smooth, uniform finish across the entire surface. This makes the parts more aesthetically pleasing and improves adhesion for coatings and paint.

3. Faster Production Times

Manual deburring is slow and inconsistent. An automated deburring polishing machine increases throughput while maintaining consistent quality across all parts.

4. Increased Tool and Machine Life

Removing burrs before further processing reduces wear on cutting tools, dies, and forming equipment. This translates to lower maintenance costs and longer tool lifespans.

5. Higher Product Quality and Customer Satisfaction

Smooth, finished parts not only look better but perform better. Investing in a proper sheet metal deburring machine ensures fewer reworks and more satisfied customers.

Technicial Parameter

| Feature | Details |

|---|---|

| Material Support | Steel, aluminum, copper, etc. |

| Processing Type | Dry / Wet |

| Working Widths Available | 600mm / 1000mm / 1300mm |

| Polishing Brushes | Optional single / dual head |

| Deburring System | Rotary brush + abrasive belt |

| Automation Level | Manual, Semi-Auto, or CNC |

Conclusion

The benefits of deburring polishing machines in sheet metal making go far beyond surface appearance. From improving safety and speed to enhancing the final product’s quality, these machines are a wise investment for any fabrication shop. If you’re still using manual tools or outsourcing this step, it’s time to bring the process in-house with a professional deburring machine sheet metal solution.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao