High-Efficiency Metal Deburring and Edge Rounding Machines for Industrial Finishing

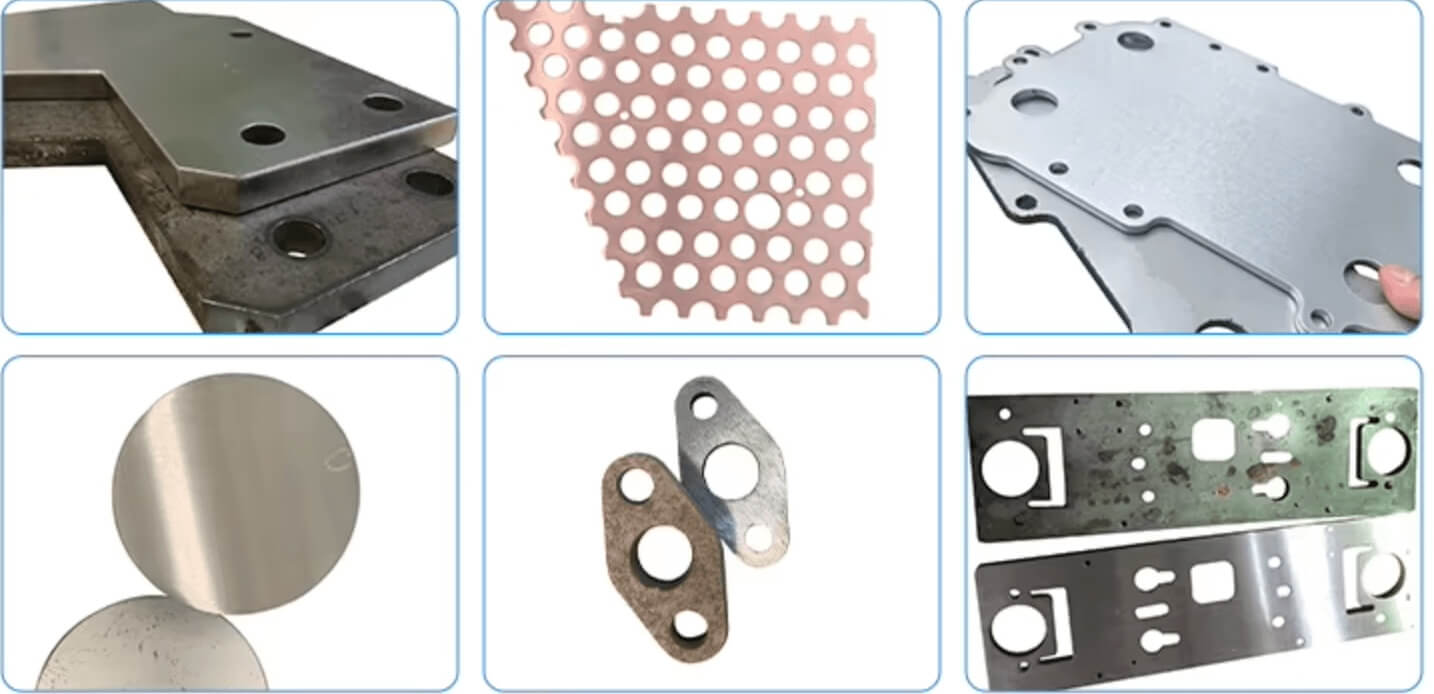

Whether you’re processing laser-cut steel plates, plasma-cut parts, or machined components, burrs and sharp edges can negatively impact performance and appearance.

If you’re searching for a metal deburring machine for sale or comparing different options — including metal deburring tumbler machines — this guide will help you understand which solution fits your needs and how to choose the right one.

Table of Contents

What Are Metal Deburring and Edge Rounding Machines?

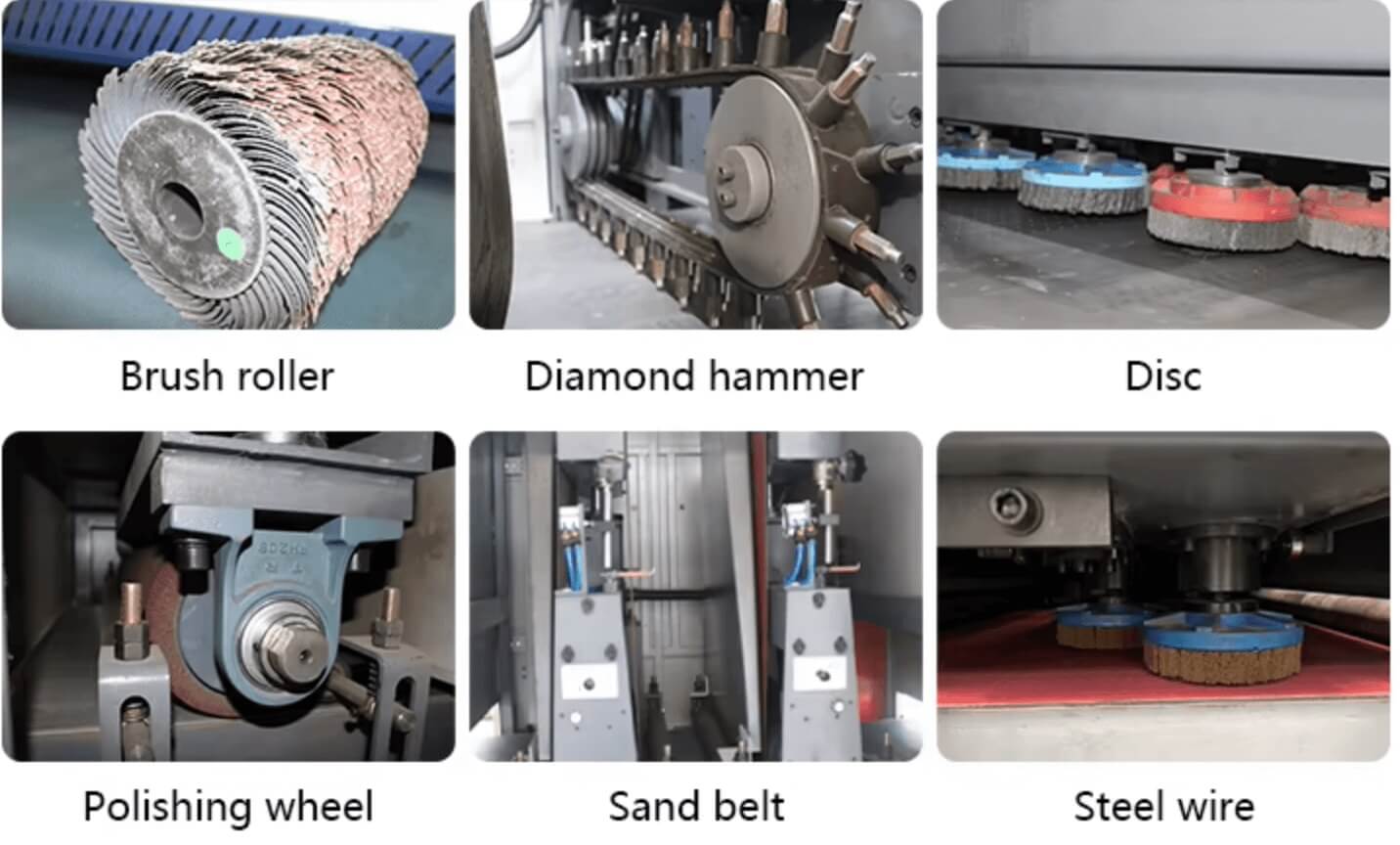

Metal deburring machines are industrial-grade tools used to remove sharp edges, burrs, and oxide layers from metal parts. When combined with edge rounding functionality, these machines provide safe, smooth finishes on both inner and outer contours.

They are essential in:

- Sheet metal processing

- CNC machining

- Laser or plasma cutting

- Fabrication of stainless steel, aluminum, and carbon steel components

Types of deburring machines include:

- Belt-type edge deburring machines

- Rotary brush machines

- Vibratory deburring (tumbler) machines

- Centrifugal barrel or drum systems

Benefits of Using a Metal Deburring Machine

- Improved Product Quality: Consistent finishes reduce the risk of coating failure, rust, or improper assembly.

- Enhanced Safety: Removing sharp edges protects workers and end-users.

- Increased Efficiency: Automated deburring replaces slow and inconsistent manual grinding.

- Supports Downstream Processes: Prepares parts for welding, powder coating, or painting.

What Is a Metal Deburring Tumbler Machine?

A metal deburring tumbler machine is a vibratory finishing system that uses abrasive media and rotational force to smooth and polish small to medium-sized metal parts. It is highly effective for high-volume batch processing, particularly for complex shapes that are difficult to deburr manually.

Key features:

- Ideal for nuts, bolts, die-cast parts, or stamped components

- Can be dry or wet (with compound and water)

- Efficient for small shops and mass production factories

- Optional drying and polishing steps available

Applications of Deburring and Edge Rounding Machines

These machines are commonly used in:

- Metal enclosure manufacturing

- Automotive parts production

- Aerospace and defense sheet metal work

- Electronics and appliance component finishing

- Cutting shops for stainless steel, copper, and aluminum

Choosing the Right Metal Deburring Machine for Sale

When browsing metal deburring machines for sale, consider:

- Type of material you process (e.g., stainless steel, aluminum)

- Part size and shape

- Required throughput or batch size

- Dry vs. wet deburring method

- Desired finish level (light edge rounding or mirror polishing)

Buying directly from a reliable manufacturer or factory ensures better after-sales support, custom machine options, and long-term value.

Technical Specifications

| Feature | Specification |

|---|---|

| Working Width | 600mm / 1000mm / 1300mm |

| Part Thickness | 0.5mm–100mm |

| Deburring Type | Brush, belt, or tumbler drum |

| Edge Rounding Radius | Up to 2mm |

| Operation Mode | Manual, Semi-auto, CNC |

| Power Supply | 380V 50Hz / Customizable |

Conclusion

Whether you need a large-format metal deburring and edge rounding machine for sheet metal or a compact metal deburring tumbler machine for small components, investing in the right solution will elevate your production quality, improve safety, and reduce labor costs. Explore the best metal deburring machines for sale to match your material types, volume needs, and finishing requirements.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao