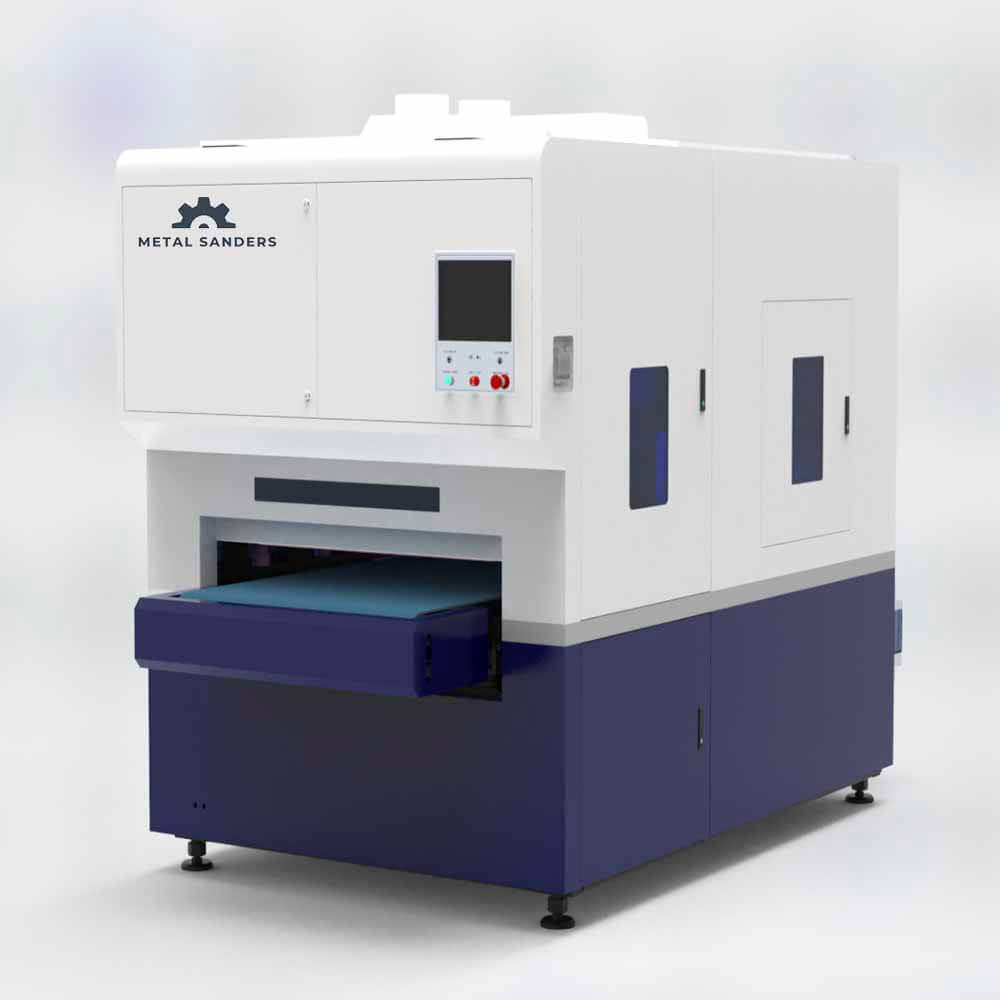

Flat Metal Deburring Machine for Smooth and Safe Sheet Metal Edges

Our flat metal deburring machine is engineered to solve these problems with speed and consistency. Designed for industrial-scale operations, it delivers uniform edge rounding and deburring for all types of flat sheet metal.

Whether you process stainless steel, aluminum, or carbon steel, our metal deburring machines help you achieve clean, safe, and professional-looking parts—every time.

Table of Contents

Why Choose Our Metal Edge Deburring Machine?

- Specialized for Flat Sheet Metal – Designed to handle flat panels and cut pieces with consistent surface contact.

- Fully Automatic Operation – Minimal manual labor, ideal for integration with laser or plasma cutting lines.

- Edge Rounding & Surface Finishing – Removes burrs and sharp edges while enhancing surface uniformity.

- Suitable for Various Metals – Compatible with stainless steel, mild steel, galvanized sheet, and aluminum.

- Heavy-Duty Construction – Built for industrial workloads with long-term durability and stability.

- Time & Cost Saving – Speeds up production, reduces rework, and improves workplace safety.

These metal edge deburring machines are essential for manufacturers focused on product quality and operator safety.

Key Features of the Flat Metal Deburring Machine

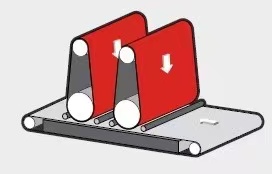

- Rotary Brush + Belt Grinding System – Combines vertical deburring and surface polishing in one pass.

- Adjustable Conveyor Speed – Adapts to different material types and thicknesses.

- User-Friendly Control Panel – PLC with touchscreen for simple setup and monitoring.

- Dry Deburring System – No need for coolant or additional drying equipment.

- Optional Dual-Side Processing – Simultaneous top and bottom deburring improves efficiency.

- Efficient Dust Collection Port – Keeps your workshop clean and compliant with safety regulations.

With a modular design, our metal deburring machines can be customized to your specific production needs.

Applications Across Metalworking Industries

Our flat metal deburring machines are widely used in:

- Laser Cutting and Plasma Cutting Workshops

- Sheet Metal Fabrication Plants

- Automotive and Aerospace Manufacturing

- Electrical Cabinets and Enclosures Production

- HVAC and Kitchen Equipment Manufacturing

Whether it’s improving paint adhesion, preventing injury, or achieving consistent part quality, our machines make it easier.

Technical Specifications of the Metal Deburring Machine

| Parameter | Value |

|---|---|

| Max Working Width | 600 mm / 1000 mm / 1300 mm (optional) |

| Material Thickness Range | 0.5 – 100 mm |

| Deburring Method | Abrasive belt + rotary brush system |

| Conveyor Speed | 0.5 – 8 m/min (adjustable) |

| Machine Type | Dry deburring |

| Control System | PLC + Touchscreen |

| Motor Power | 7.5 kW – 15 kW |

| Material Compatibility | Carbon steel, stainless steel, aluminum |

| Dust Collection Interface | Standard port for external extraction |

Conclusion

Our flat metal deburring machine is the perfect choice for manufacturers looking to automate and improve edge finishing. With a focus on safety, precision, and productivity, this system reduces rework, enhances product quality, and increases throughput.

Whether you’re working with thin aluminum or thick stainless steel plates, our metal deburring machines deliver the reliability and performance your operation demands. Trust our metal edge deburring machine to take your finishing process to the next level.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao