Sheet Metal Deburring Machine for Sale – Automate Edge Rounding & Surface Finishing

Our automatic flat metal sheet deburring machine offers an industrial-grade solution to remove sharp burrs and oxidation from laser-cut, plasma-cut, or punched metal parts. Whether you’re processing stainless steel, aluminum, or carbon steel, this machine ensures smooth edges and a flawless surface finish.

Perfect for manufacturers aiming to improve productivity and safety, our solution combines the latest brush and abrasive belt technology to transform your metalworking workflow.

Table of Contents

Why Choose an Automatic Flat Metal Sheet Deburring Machine?

Our machine is designed to meet the high demands of modern fabrication environments:

- Fully Automated Workflow – Eliminates manual grinding, saving time and labor.

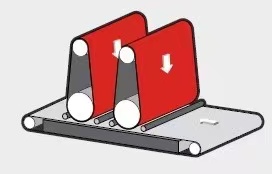

- Dual-Side Deburring Available – Top and bottom surfaces deburred in a single pass.

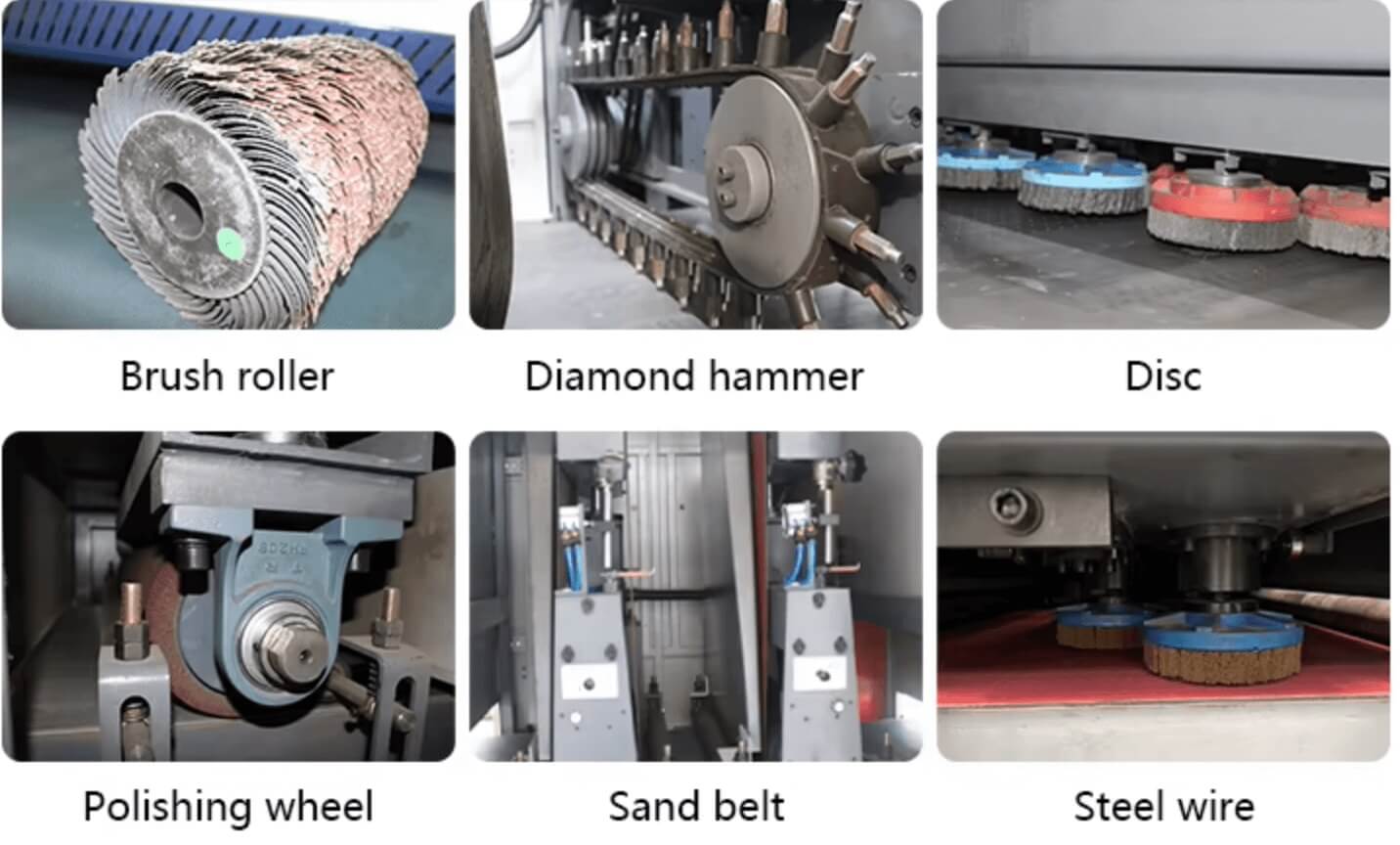

- Rolling Brush Technology – Ideal for oxide layer removal and uniform edge rounding.

- Supports Various Sheet Sizes – Suitable for wide-format sheet metal panels.

- Improved Operator Safety – Removes dangerous burrs that can cause injury.

- Consistent Quality – Every part is finished to the same high standard.

- Whether you run a small shop or a large production facility, investing in an automatic flat metal sheet deburring machine is a smart move for both quality and efficiency.

Key Benefits of Using a Metal Rolling Brush Deburring Machine

If you’re considering upgrading your finishing equipment, here are the benefits of using a metal rolling brush deburring machine:

- Edge Rounding Without Part Damage – Gentle brush action preserves part dimensions and integrity.

- Oxide Removal for Welding Prep – Cleans oxide from laser-cut edges to improve weld penetration.

- Surface Conditioning – Helps with paint and powder coating adhesion.

- No Coolant Required – Dry processing simplifies operation and maintenance.

- Lower Tooling Cost – Rolling brushes have longer life cycles than abrasive belts alone.

- Ideal for Complex Shapes – Brushes reach uneven surfaces that belts cannot.

This technology is essential for industries where both surface quality and precision matter.

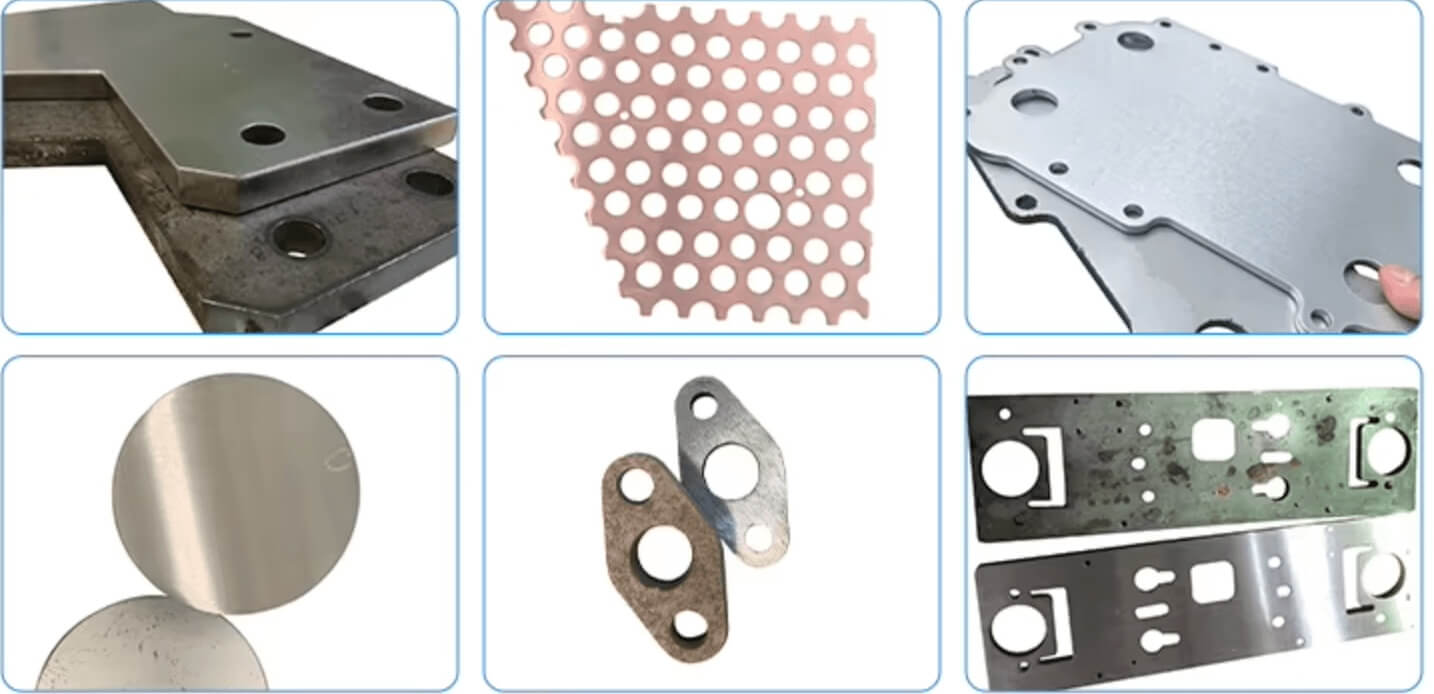

Applications of Our Deburring Machine

This machine is suitable for a wide range of metal fabrication needs, including:

- Laser-cut part finishing

- HVAC duct and panel production

- Electrical cabinet and box manufacturing

- Elevator and appliance panel processing

- Aerospace, automotive, and kitchen equipment components

Whether you’re working with flat plates or punched panels, this sheet metal deburring machine for sale delivers reliable, high-speed performance.

Technical Specifications

| Parameter | Specification |

|---|---|

| Working Width | 600mm / 1000mm / 1300mm / Custom |

| Material Thickness | 0.5 – 100mm |

| Deburring Method | Rolling brush + abrasive belt (dry) |

| Conveyor Speed | 0.5 – 8 m/min (adjustable) |

| Brush Motor Power | 3.0 – 5.5kW |

| Control Interface | Touchscreen with PLC control |

| Material Compatibility | Stainless steel, carbon steel, aluminum |

| Dust Collection | External port included |

Conclusion

Investing in our automatic flat metal sheet deburring machine means more than just smoother edges—it means safer products, faster workflows, and lower long-term costs. The metal rolling brush deburring technology provides a perfect balance between surface refinement and edge rounding, helping you deliver parts that are not only precise but ready for final assembly or coating.

If you’re looking for a sheet metal deburring machine for sale that offers industrial reliability, consistent output, and scalable automation, this is your solution.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao