High-Performance Sheet Metal Deburring Machines for Flat Part Finishing

Whether you’re working with laser-cut panels, plasma-cut plates, or punched flat metal parts, burrs and sharp edges can’t be ignored. Our advanced flat metal deburring machines are engineered to deliver smooth, burr-free surfaces that meet strict quality and safety standards.

Table of Contents

Key Features of Our Sheet Metal Edge Deburring Machine

- Precision Edge Deburring

Designed specifically for edge treatment, this sheet metal edge deburring machine ensures all edges are safely rounded and free of burrs — ideal for parts entering painting or welding processes. - Wide Format Capacity

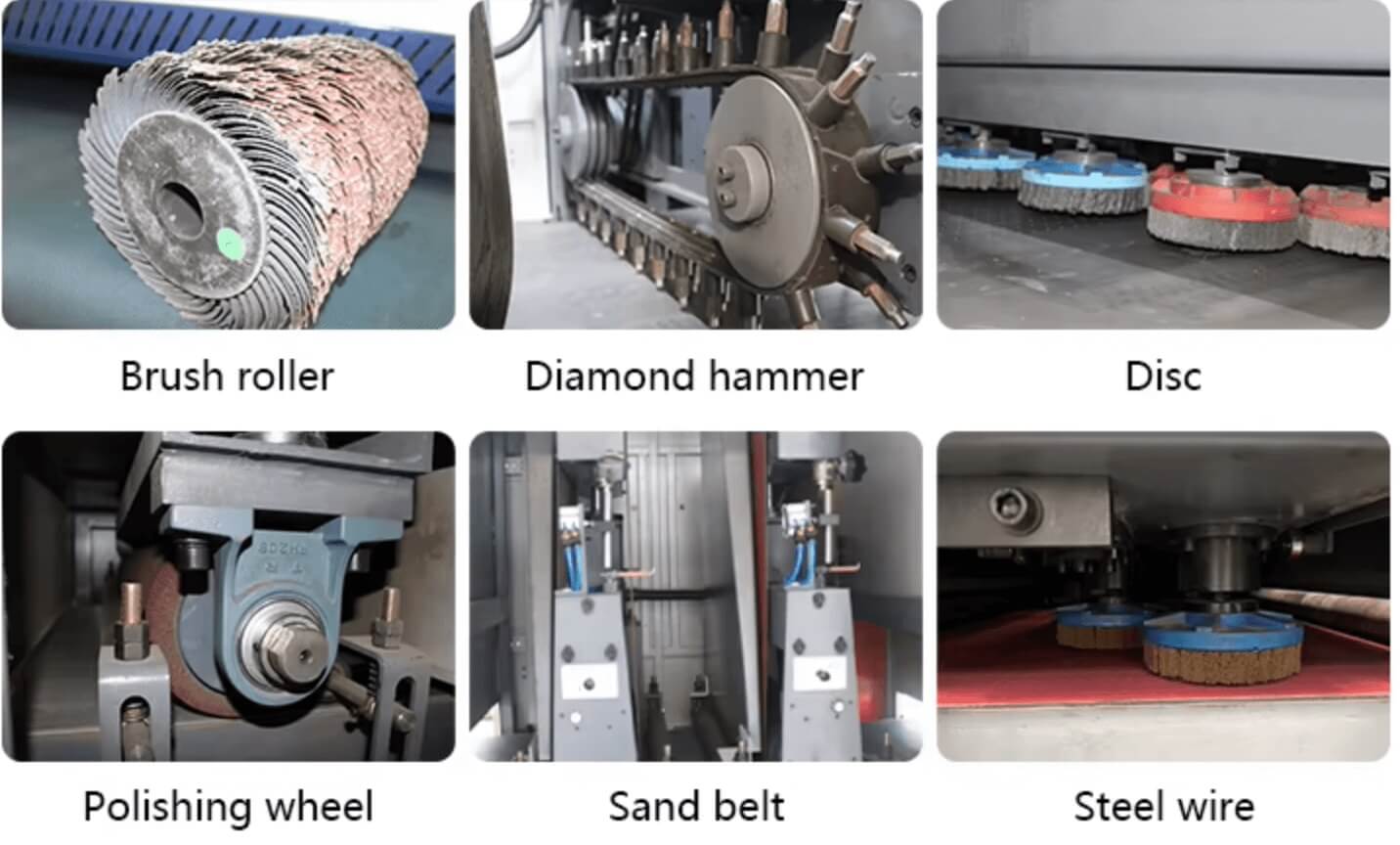

Our flat metal deburring machines come in various working widths (600mm–1300mm) to accommodate everything from small components to large sheet metal panels. - Rotating Brush + Belt Combination

Dual-action abrasive systems guarantee complete removal of microburrs and oxide layers on both edges and surfaces. - Automatic Thickness Detection

Adjusts in real-time to varying part thickness, improving workflow speed and reducing the need for manual setup. - Dry or Wet Deburring Modes

Choose between dry systems for cost-effective cleaning, or wet systems for dust-free, cooler operations — both available for your shop needs. - Stainless Steel-Friendly Construction

Rust-proof components make this the perfect sheet metal deburring machine for stainless steel and aluminum processing environments.

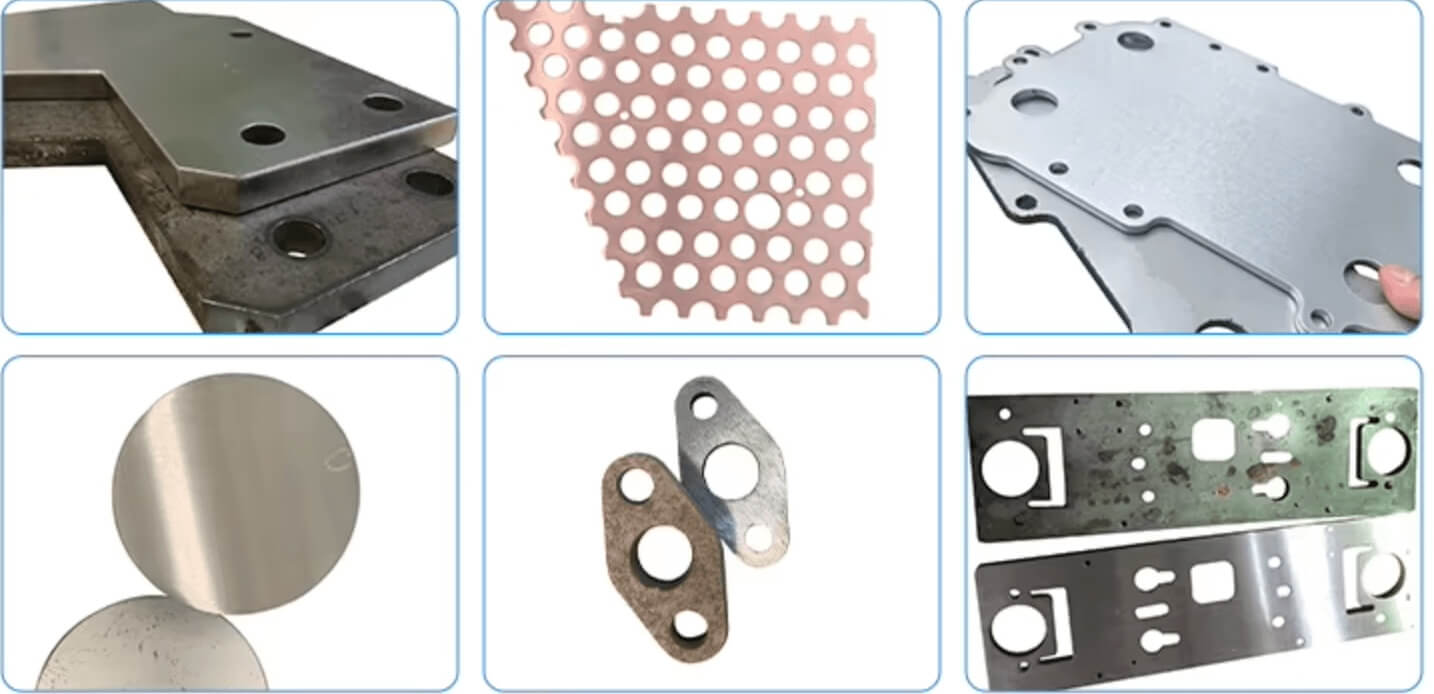

Applications

These machines are ideal for:

- Flat Sheet Deburring After Laser or Plasma Cutting

- Deburring Edges of Electrical Cabinets, Panels, and Doors

- Finishing Automotive or Aerospace Sheet Components

This makes our equipment the perfect solution for any production line seeking a reliable, high-speed sheet metal edge deburring machine.

Technical Specifications

| Parameter | Value |

|---|---|

| Working Width | 600mm / 1000mm / 1300mm |

| Material Thickness | 0.5mm – 100mm |

| Processing Type | Dry / Wet |

| Deburring System | Rotary brush + Wide belt combo |

| Conveyor Speed | 0–10 m/min adjustable |

| Power Supply | 380V 50Hz / Customizable |

| Dust Collection | Optional internal/external unit |

Why Choose Our Flat Metal Deburring Machines?

- High Efficiency – Reduce manual grinding time by up to 80%.

- Consistent Finish – Perfect, repeatable edge and surface results every time.

- Operator Friendly – Easy-to-use touchscreen controls and minimal setup.

- Adaptable Design – Modular units allow upgrades for polishing, oxide removal, and more.

Conclusion

In today’s metal fabrication industry, precision and safety are non-negotiable. Our sheet metal deburring machines offer the performance, versatility, and durability you need to maintain high standards while streamlining your workflow. Whether you need a flat metal deburring machine for stainless steel sheets or a compact sheet metal edge deburring machine for high-volume edge rounding, we have the solution.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao