Metal Sheet Sander Machine & Polishing Machine Solutions

Let’s explore the top-performing sanding and polishing machines for metal, their key functions, and expert tips to help you choose the best solution for your application.

Table of Contents

What Is a Metal Sheet Sander Machine?

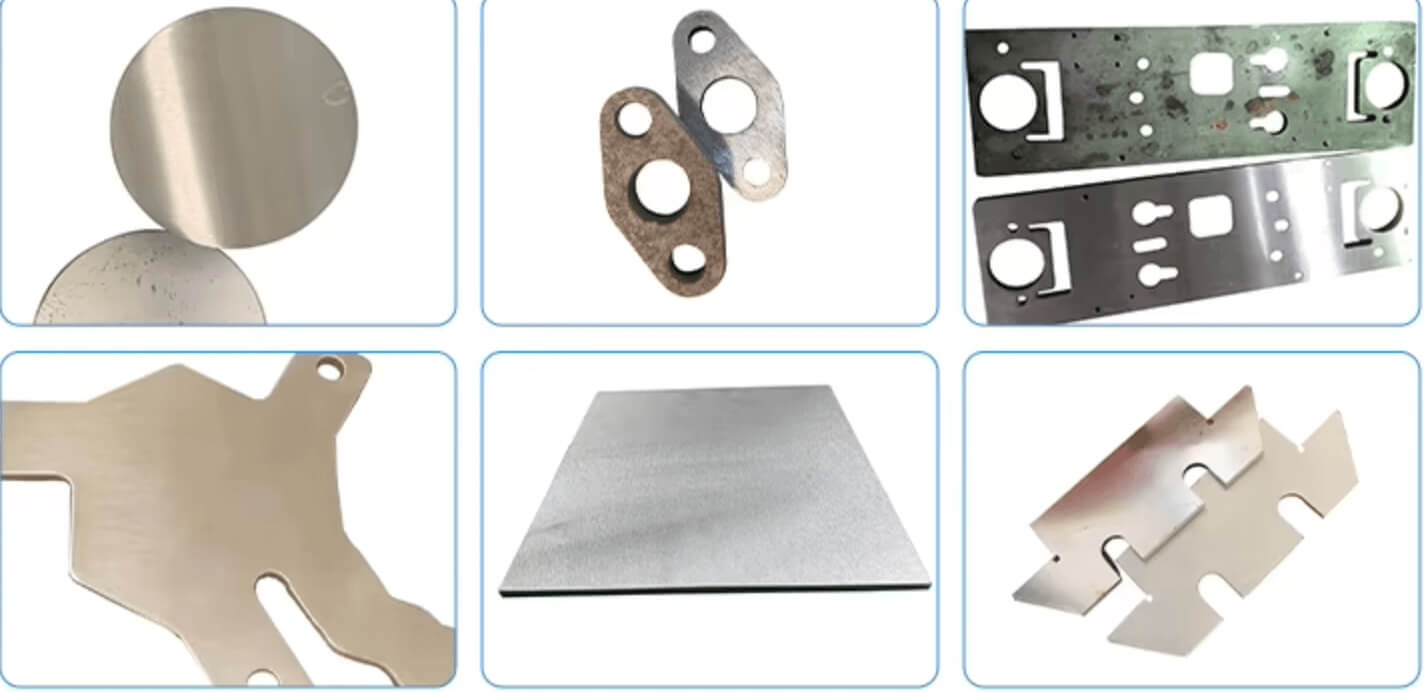

A Metal Sheet Sander Machine is designed for precision sanding of flat metal parts like sheets, plates, and formed components. These machines efficiently remove oxidation, scratches, welding marks, and prepare surfaces for further polishing or coating.

Key Advantages:

Wide sanding area for large-format metal parts

Suitable for stainless steel, aluminum, and iron sheets

Consistent surface roughness for improved coating and bonding

Reduces manual labor, increases productivity

Sanding Machine for Polishing: Beyond Grinding

The Sanding Machine for Polishing goes a step further—offering controlled polishing after initial sanding. This type of machine supports various abrasive media such as flap wheels, polishing pads, and scouring wheels to deliver anything from a brushed finish to a mirror-like sheen.

Benefits:

▶ Delivers decorative finishes on stainless steel or aluminum

▶ Great for kitchenware, signage, panels, and decorative metal sheets

▶ Works with both flat and slightly contoured metal parts

▶ Can be integrated with CNC control for precision polishing paths

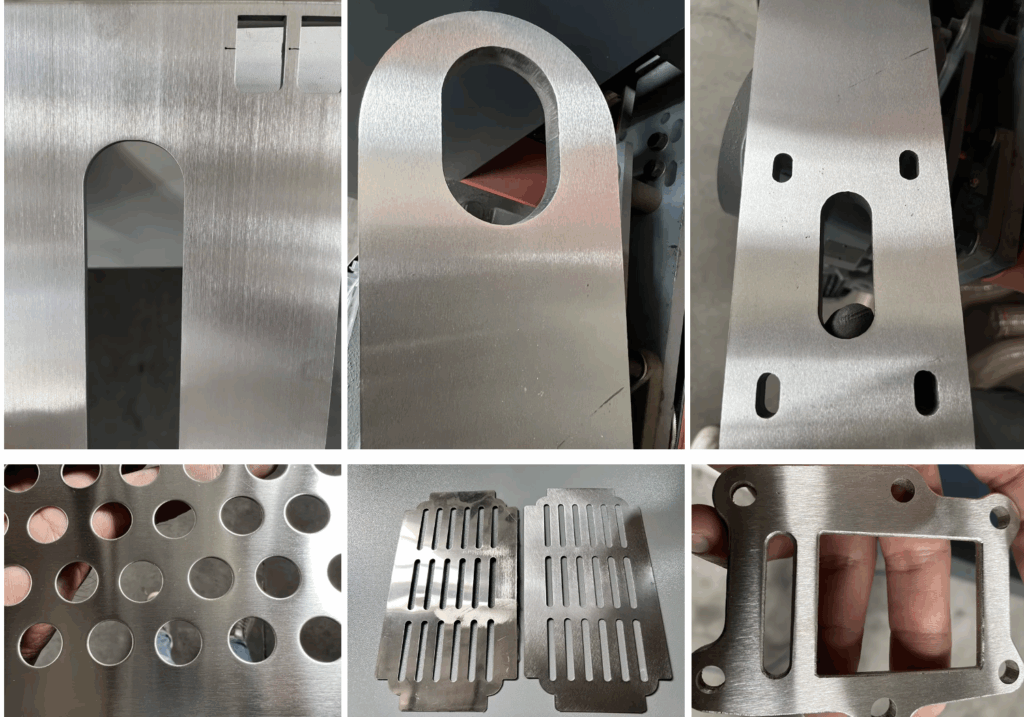

Sander Machine for Metal: Multi-Function Surface Solution

A Sander Machine for Metal combines sanding, deburring, edge rounding, and finishing functions in a single setup. It’s a powerful, time-saving solution for batch processing of laser-cut or plasma-cut parts.

Capabilities:

Deburrs sharp edges on cut metal sheets

Rounds corners for improved safety and functionality

Produces uniform surface texture

Wet/dry configurations available for environmental control

Technical Specifications

| Item | Specification |

|---|---|

| Working Width | 1000 mm |

| Working Thickness | 0.5 – 100 mm |

| Abrasive Belt Size | 1000 × 2000 mm |

| Feed Speed | 5 – 30 m/min (adjustable) |

| Main Motor Power | 18.5 – 22 kW (customizable) |

| Polishing Motor Power | 4 kW × 2 |

| Dust Port | 3 × Φ150 mm |

| Dimensions (L×W×H) | 2600 × 1900 × 2100 mm |

| Total Weight | ≈ 2500 kg |

Where Are These Machines Used?

These sanding and polishing machines are indispensable in:

Architectural Panels – stainless steel with hairline or mirror finish

Appliance Manufacturing – brushed aluminum or steel surfaces

Custom Metal Fabrication – signage, furniture, lighting fixtures

Automotive – deburring and polishing of stamped sheet metal

HVAC and Elevator Industry – smooth sheet surfaces, rounded edges

How to Select the Right Machine for Your Needs?

When choosing your Metal Sheet Sander or Polisher, consider the following:

Material Type: Stainless steel, aluminum, galvanized sheet, copper

Finish Goal: Pre-coating prep, brushed finish, or mirror polish

Sheet Size & Volume: Wider belts and CNC features for high-volume use

Abrasive Compatibility: Support for belts, wheels, brushes, pads

Automation Level: Manual vs. semi-auto vs. full CNC control

Safety & Cleanliness: Dust collection, wet sanding, or fume control

Conclusion

Surface preparation is the foundation of excellent metalwork. Whether you’re polishing appliance panels or deburring custom laser-cut parts, a precision-engineered Metal Sheet Sander Machine, Sanding Machine for Polishing, or Sander Machine for Metal will streamline your workflow and boost final quality.

👉 Contact our team today to get a personalized machine recommendation and competitive quote.

Conclusion

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao