Wide Belt Sander Metal High Performance Wide Belt Sander Machine

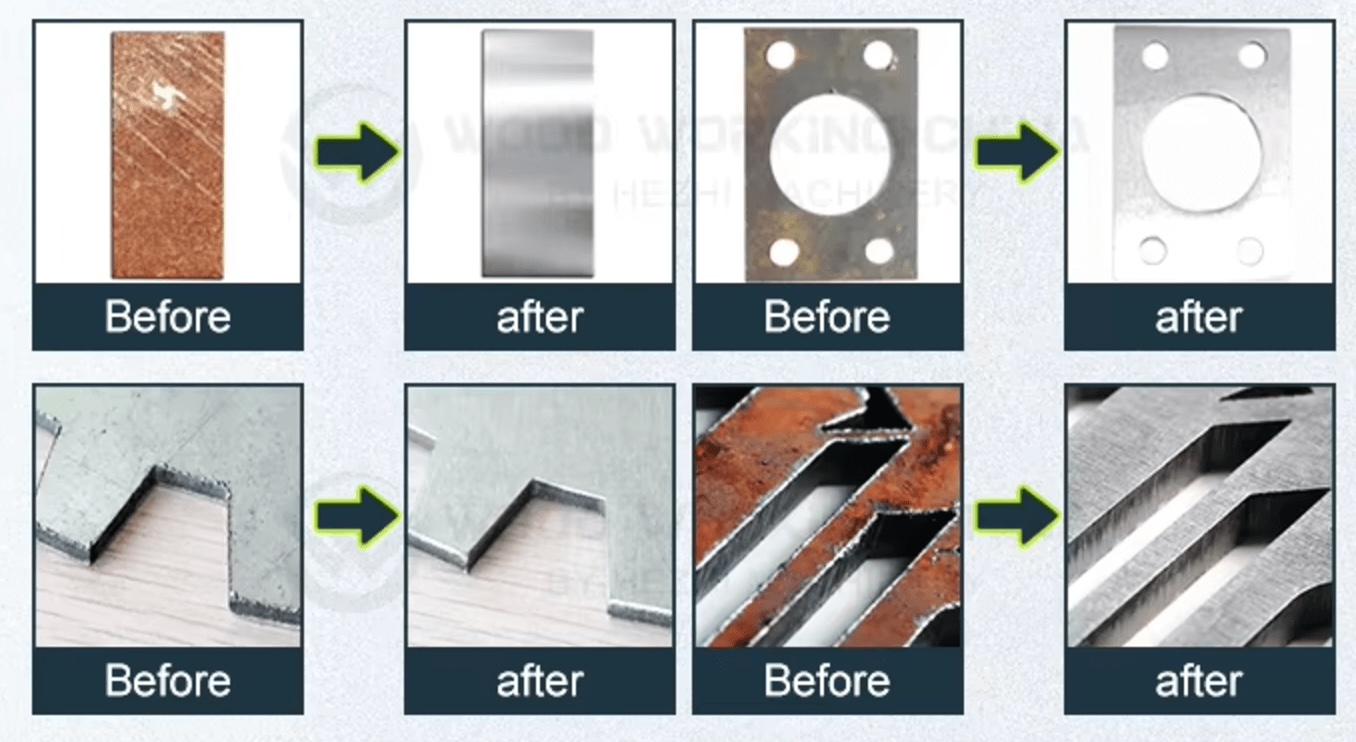

This advanced wide belt sander machine offers outstanding performance in metal deburring, slag removal, and surface polishing, making it an essential piece of equipment for sheet metal processing plants, fabrication workshops, and stainless steel product manufacturers.

Thanks to its robust structure, automated sanding functions, and high consistency, this metal sanding machine delivers smooth and uniform finishes across a wide range of materials including stainless steel, mild steel, aluminum, and more.

Table of Contents

Key Features of the Wide Belt Sander Metal – Efficient Sheet Metal Finishing Machine

Heavy-Duty Frame and Belt System — Built with industrial-strength components, this industrial metal sander features a rigid frame and durable belt that ensure high sanding precision and minimal vibration during heavy workloads.

Variable Speed Control — The wide belt sander machine offers adjustable conveyor and belt speeds, allowing operators to customize the sanding process according to metal thickness, hardness, or surface condition.

Multiple Sanding Heads — Equipped with one or more sanding heads (abrasive belt, brush, or roller), it ensures flexibility in operations such as deburring, edge rounding, oxide removal, or fine finishing.

Dust Collection and Filtration System — Integrated dust extraction ports help maintain a clean and safe working environment during continuous use of this metal sanding machine.

Smart Touchscreen Interface — With its user-friendly control panel, the operator can easily monitor and adjust working parameters, improving operation efficiency and reducing training time.

Modular Expandability — The system is scalable for different production needs, making it a reliable sheet metal finishing machine that can grow with your business.

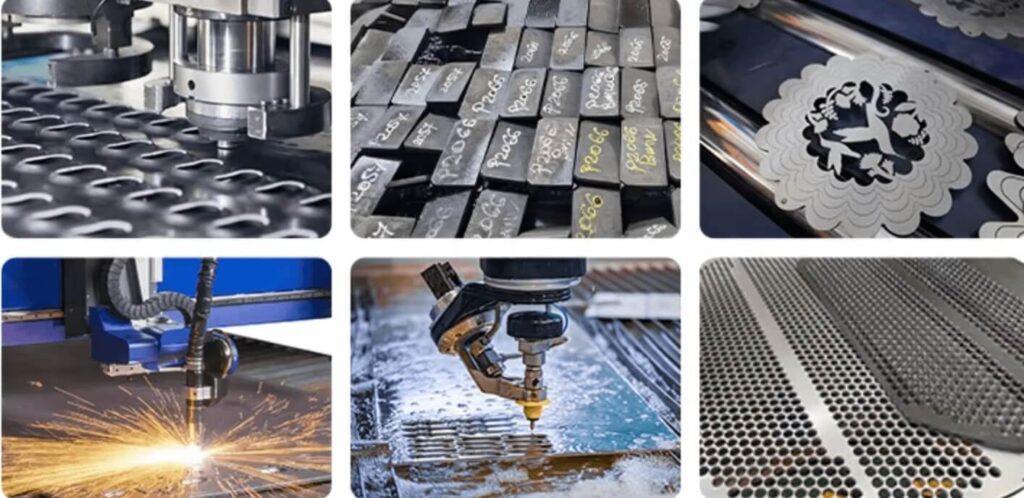

Applications

The wide belt sander metal is ideal for:

Deburring laser-cut or plasma-cut metal parts

Oxide film removal from stainless steel sheets

Surface polishing and finishing of aluminum or galvanized panels

This makes it the ideal stainless steel sander and metal sanding machine for medium to large-scale metal fabrication operations.

Technical Specifications

| Parameter | Value |

|---|---|

| Working Width | 1000mm / 1300mm / 1600mm |

| Workpiece Thickness | 0.5mm – 100mm |

| Sanding Belt Size | 1330 × 2200mm |

| Main Motor Power | 30kW – 45kW (customizable) |

| Conveyor Speed | 5–30 m/min |

| Voltage | 380V / 50Hz / 3-Phase |

| Weight | Approx. 3000–4500kg |

| Control System | PLC + Touchscreen Interface |

Why Choose This Metal Sanding Machine?

Increased Productivity — The wide belt sander metal streamlines the sanding process, significantly improving output for mass production.

Consistent High-Quality Finish — Delivers uniform surface treatment, ideal for parts that require powder coating or welding post-processing.

Versatile for Multiple Materials — Whether you’re working with stainless steel, aluminum, or carbon steel, this stainless steel sander adapts to your specific needs.

This high-performance metal sanding machine is an all-in-one solution for sheet metal fabricators looking for precision, durability, and efficiency.

Customer Feedback

“This wide belt sander machine has cut our sanding time in half. It’s powerful, reliable, and gives a perfect finish on stainless steel panels.”

— Workshop Manager, Sheet Metal Factory

“We used to sand parts manually. This industrial metal sander automated our process and increased our output by 40%.”

— CEO, Custom Metal Fabrication Business

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao