Choosing the Best Belt Sander for Metal Work and Fabrication

Whether you’re shaping, grinding, or finishing metal, the right sanding machine can save time and improve results. If you’re searching for the best belt sander for metal work, it’s important to understand your options and how they fit into your fabrication process.

Table of Contents

Why You Need the Best Belt Sander for Metal Work

A belt sander for metal work is designed to handle heavy-duty tasks like grinding sharp edges, removing rust, smoothing weld seams, and preparing surfaces for painting or coating. Unlike wood sanders, a metal belt sander is built to resist heat, pressure, and the hardness of metal materials.

Investing in the best belt sander for metal work ensures:

Higher efficiency on tough materials like steel, iron, and aluminum.

Smooth, even finishes without damaging the workpiece.

Consistent performance for both small and large-scale metal projects.

Belt Sander for Metal Fabrication — A Workshop Essential

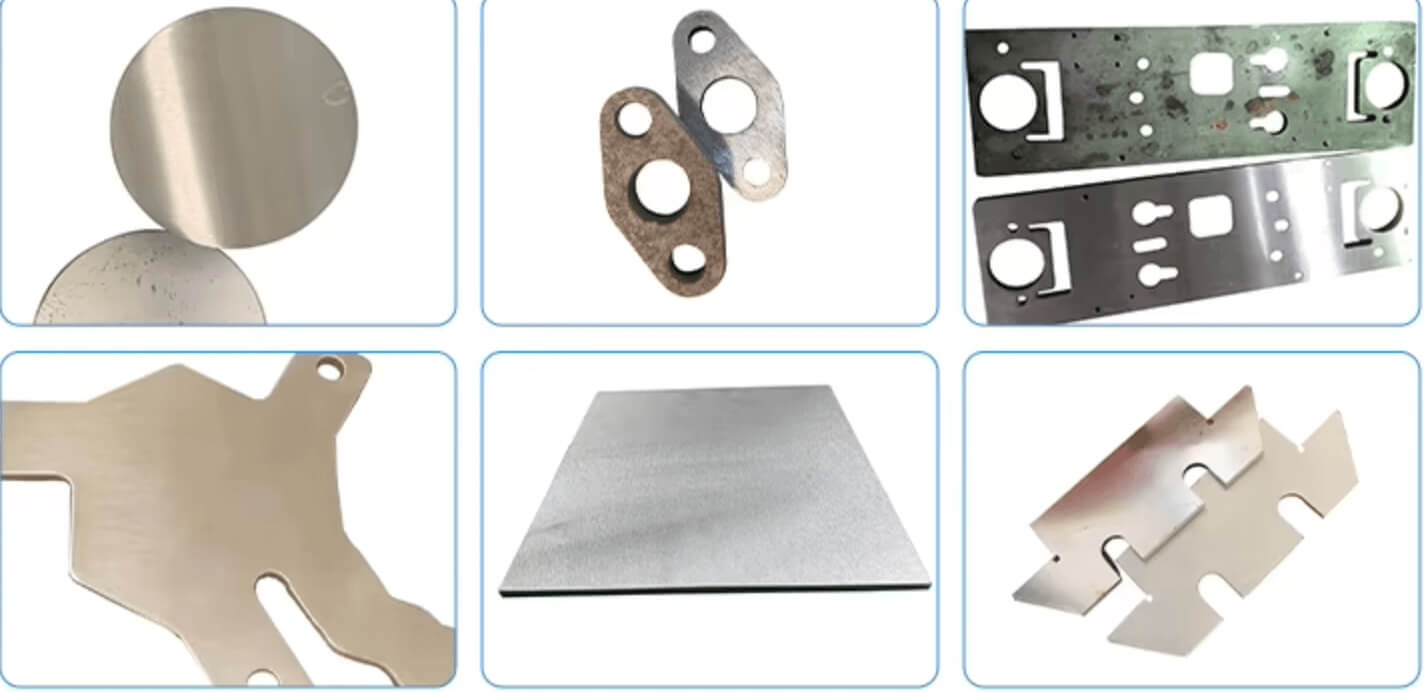

A belt sander for metal fabrication is more than just a convenience; it’s an essential part of any professional metal shop. These machines are designed for shaping raw material, cleaning up welds, removing scale, and preparing surfaces for finishing.

Benefits of using a belt sander for metal fabrication include:

Increased speed and productivity on metal finishing tasks.

Reduced manual grinding and labor fatigue.

Versatility for various fabrication jobs, from small parts to large frames.

Whether you’re working on sheet metal, pipes, or structural steel, a belt sander for metal fabrication ensures clean, professional results every time.

Why Choose a Vertical Belt Sander for Metal?

A vertical belt sander for metal offers a different setup compared to traditional horizontal machines. With a vertical configuration, this type of sander gives operators better control and visibility during detailed finishing tasks.

Advantages of a vertical belt sander for metal:

Space-saving design for workshops with limited floor space.

Excellent control for precision sanding and fine finishing.

Ideal for deburring, polishing, and edge rounding.

A vertical belt sander for metal is especially useful for small workshops or industrial settings that require versatility and compact design without sacrificing performance.

Conclusion

When you’re choosing equipment for your workshop, selecting the best belt sander for metal work can improve both productivity and finish quality. Whether you prefer a belt sander for metal fabrication or a vertical belt sander for metal, investing in the right machine will ensure smooth, safe, and efficient metalworking.

Looking for professional-grade belt sanders for your shop? Contact us today for expert recommendations and high-quality machines designed to meet the toughest metal fabrication needs!

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao