630mm 1000mm Industrial Metal Belt Sander Wide Belt Sanding Machine for Metal Work

Whether you are working with stainless steel, aluminum, iron, or brass, a 630mm 1000mm Industrial Metal Belt Sander Wide Belt Sanding Machine is designed to deliver consistent and high-quality results.

If you’re searching for the best belt sander for metal work or a reliable metal belt grinder for knife making, this machine offers the power, versatility, and durability needed for both industrial production and fine craftsmanship.

Table of Contents

What is an Industrial Metal Belt Sander?

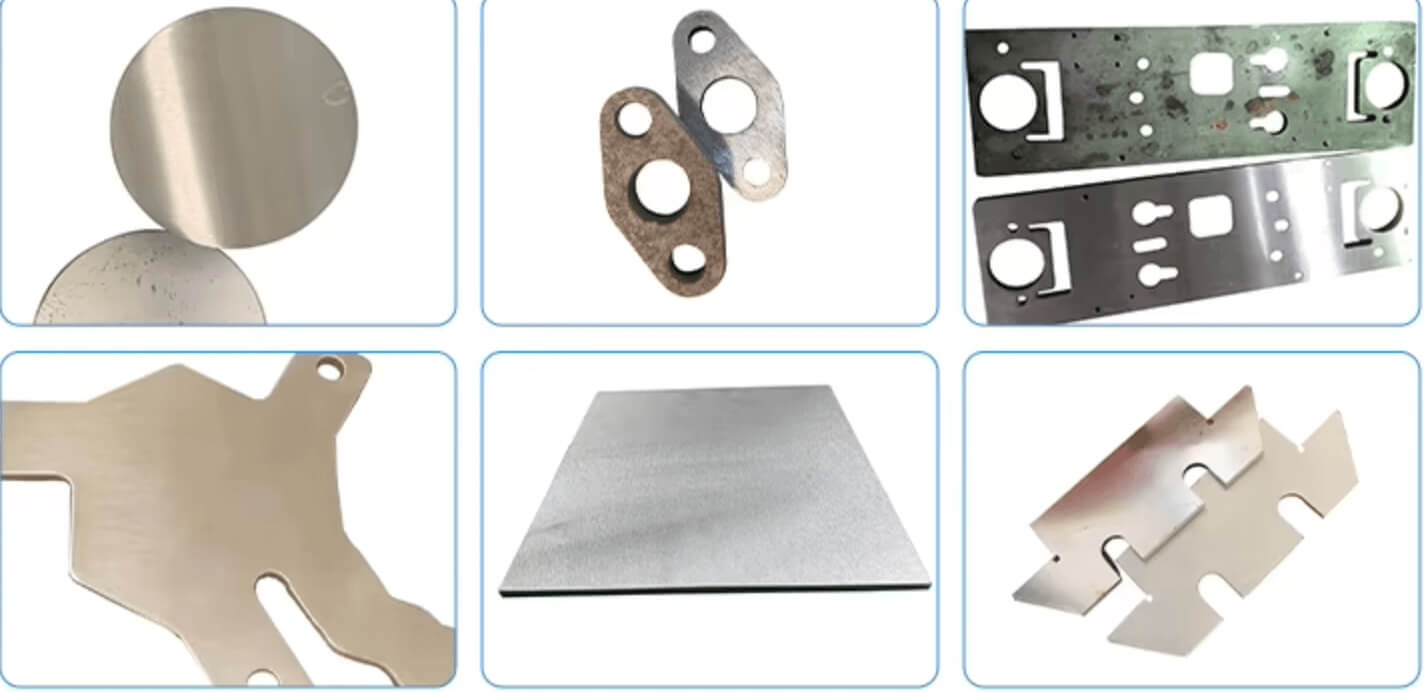

An Industrial Metal Belt Sander is a heavy-duty sanding machine designed for processing large and thick metal sheets, parts, and components. This type of machine uses a wide abrasive belt to smooth, deburr, and polish metal surfaces efficiently.

The 630mm and 1000mm wide belt sanding machines are ideal for manufacturers who demand precise surface finishes and increased productivity. Whether you’re preparing metal parts for welding or final polishing, this machine ensures a uniform and professional result every time.

Key Features of the 630mm 1000mm Wide Belt Sanding Machine

- High Precision Sanding

Designed with a robust frame and advanced control systems, this machine guarantees accurate and smooth surface finishing for all types of metal sheets. - Heavy-Duty Construction

Built for industrial-grade workloads, this industrial metal belt sander features a powerful motor and reinforced steel structure, ensuring stability and long-term durability. - Versatile Applications

Suitable for metal work, including sheet metal fabrication, knife making, and parts deburring. Whether you are involved in mass production or artisanal projects, this machine can handle it all. - Efficient Dust Collection System

Equipped with an integrated dust extraction design, the machine minimizes airborne particles, providing a cleaner, safer work environment.

Why Choose the Best Belt Sander for Metal Work?

Choosing the best belt sander for metal work is critical for achieving professional-level results while reducing production time and labor costs. The 630mm and 1000mm models are tailored for:

Sheet Metal Fabrication

Structural Steel Work

Knife Blade Polishing

Metal Furniture Manufacturing

Deburring After Laser or Plasma Cutting

Their wide belt surface, adjustable speed settings, and user-friendly interface make them ideal for both seasoned machinists and metal artists.

Metal Belt Grinder for Knife Making: The Ultimate Craftsmanship Tool

If you are involved in knife making, the metal belt grinder for knife making is an indispensable tool. These machines offer:

- Precise Angle Control for perfect bevels and edges.

- Variable Speed Options to adjust according to material hardness.

- Strong Abrasive Belts to handle both rough grinding and fine polishing.

The wide belt size (630mm and 1000mm) allows for processing not only knives but also larger metal items, making it a versatile addition to any workshop.

Conclusion

Whether you’re in industrial metal fabrication or passionate about knife making, investing in a 630mm 1000mm Industrial Metal Belt Sander Wide Belt Sanding Machine for Metal Work is a smart choice. These machines combine precision, durability, and efficiency — making them one of the best belt sanders for metal work on the market.

If you’re looking for a reliable industrial metal belt sander or a high-performance metal belt grinder for knife making, this machine will meet and exceed your expectations. Explore the possibilities of advanced sanding technology and take your metalwork projects to the next level!

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao