Automatic Metal Rr1000mm Wide Working Belt Sander Sheet Metal Sanding Deburring Machine

Designed for large-scale operations, its 1000mm wide belt accommodates oversized sheets, while automation ensures consistency across stainless steel, aluminum, and other metals. Compatible with Sand Belt Water Grinder Machines and tailored for tasks ranging from heavy deburring to mirror-like polishing, this machine is a cornerstone for industries prioritizing speed, accuracy, and versatility.

Table of Contents

Unmatched Efficiency with a 1000mm Wide Belt

The Wide Metalworking Belt Sander boasts a massive 1000mm working width, enabling rapid processing of large metal sheets, panels, and components. This expansive belt reduces the need for multiple passes, slashing production time while maintaining uniform finishes. Ideal for automotive, aerospace, and architectural applications, it handles everything from rough sanding to final polishing with ease.

Automated Deburring for Flawless Surfaces

Equipped with advanced Deburring Machine Automatic technology, this system eliminates sharp edges, burrs, and imperfections without manual intervention. Precision sensors and adjustable pressure settings ensure consistent material removal, preparing surfaces for welding, coating, or assembly. The automated process minimizes human error, making it ideal for high-volume manufacturing.

Versatility in Metalworking Applications

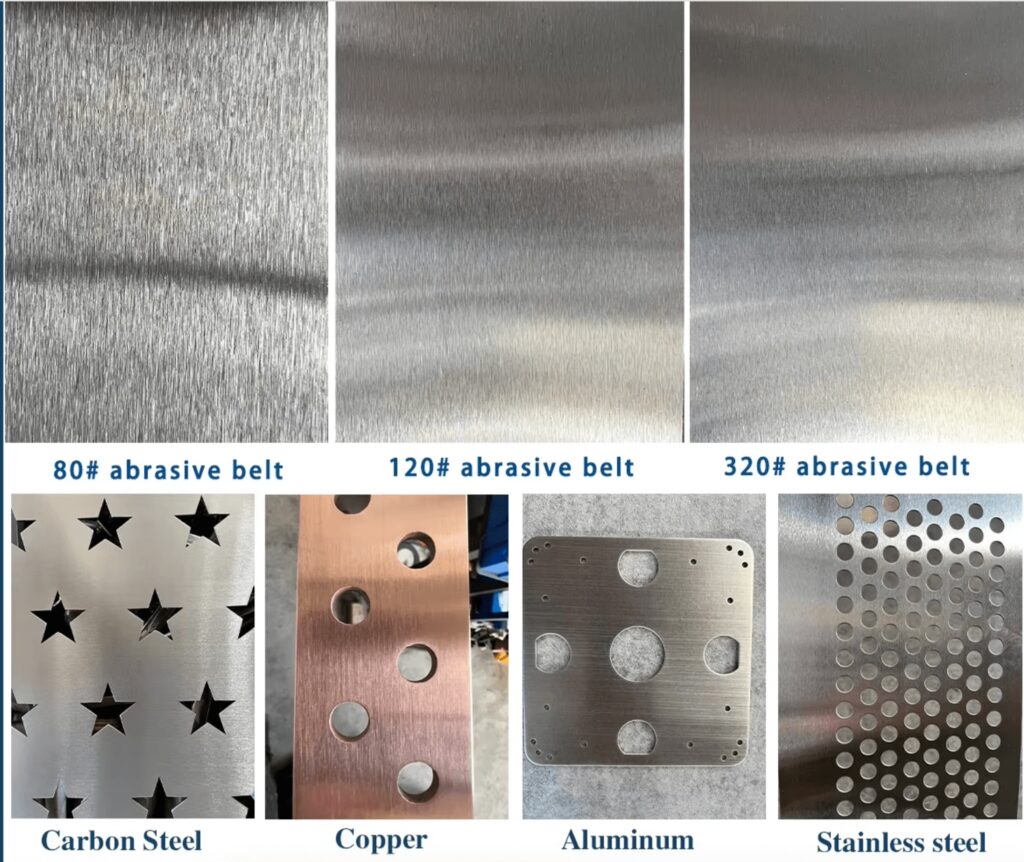

As a Sheet Metal Sanding Machine, it excels in smoothing welds, leveling surfaces, and refining textures. Transitioning into a Metal Wide Belt Polishing Machine, it delivers glossy finishes on stainless steel, brass, and alloys. Its adaptability extends to synthetic materials, offering flexibility for diverse production needs.

Integration with Sand Belt Water Grinder Systems

For industries requiring wet grinding, this sander complements Sand Belt Water Grinder Machines. The hybrid setup reduces heat buildup during intensive tasks, preventing warping and extending abrasive belt life. This integration is particularly valuable for heat-sensitive metals or achieving ultra-fine finishes.

Precision and Durability in Design

Built for industrial endurance, the machine features robust construction, high-torque motors, and easy-adjust tracking systems. Its low-maintenance design ensures longevity, even in demanding environments. Operators benefit from user-friendly controls and quick belt changes, maximizing uptime.

Conclusion: Elevate Productivity with Advanced Metal Finishing

The Automatic Metal RR1000mm Wide Belt Sander is a game-changer for modern workshops. By merging deburring, sanding, and polishing with automation and compatibility for Sand Belt Water Grinder Machines, it streamlines workflows and enhances output quality. Whether processing oversized sheets or refining intricate components, this machine empowers manufacturers to meet rigorous standards while boosting efficiency. Invest in this cutting-edge system to revolutionize your metal finishing processes and stay competitive in evolving markets.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao