1300 cm Wide Belt Sanding Machine: 30×533 Belt Sander for Abrasive Belt Metal Sanding Machinery

With a 30×533 Belt Sander, this machine is specifically designed for high-precision sanding, grinding, and finishing of metal materials. Offering advanced features and efficient operation, it is ideal for various metalworking industries that demand both speed and quality. In this article, we will explore the key features, advantages, and applications of the Abrasive Belt Metal Sanding Machinery, focusing on the innovative design of the 1300 cm wide belt sanding machine.

Table of Contents

1300 cm Wide Belt Sanding Machine: Robust Performance for Large-scale Operations

The 1300 cm Wide Belt Sanding Machine is built for industrial-grade tasks, offering large sanding capacities and consistent performance. This machine is engineered to handle demanding tasks such as deburring, finishing, and polishing large metal parts. Key features include:

- High sanding width: The 1300 cm wide sanding belt offers increased working width, allowing operators to process larger materials in one go, improving productivity and reducing handling time.

- Superior efficiency: With the ability to cover vast surface areas in less time, this sanding machine significantly speeds up the production process, making it perfect for mass production environments.

- Durable and long-lasting: Designed for long-term operation, the robust frame and high-quality components ensure the machine can withstand extended usage, making it a reliable choice for heavy-duty metalworking.

30x533 Belt Sander: Precision Sanding for Metal Surfaces

The 30×533 Belt Sander is a critical component of this sanding machine, providing the necessary abrasive action for achieving smooth, precise finishes on metal parts. Here are the benefits of using a 30×533 Belt Sander:

- Precise metal sanding: The 30×533 abrasive belt allows for high accuracy in sanding operations, helping to achieve consistent finishes across various metal parts, including stainless steel, aluminum, and iron.

- Ideal for various metalworking tasks: Whether you are deburring, finishing, or preparing metal surfaces for further treatment, the 30×533 belt sander offers exceptional versatility and efficiency in achieving the desired results.

- Customizable abrasive options: The Abrasive Belt Metal Sanding Machinery allows users to easily switch between different types of abrasive belts, tailoring the sanding process to specific tasks or materials.

Abrasive Belt Metal Sanding Machinery: The Ideal Solution for Precision and Efficiency

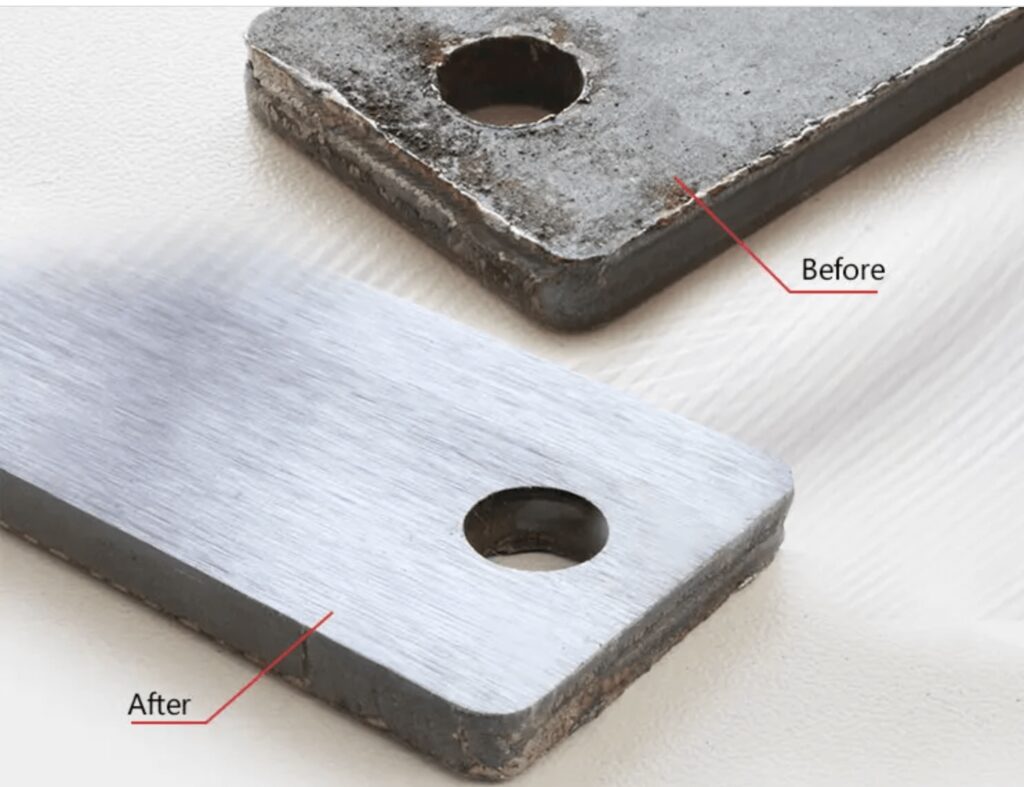

Abrasive belt sanding is a highly effective technique for metalworking, providing the necessary force to smooth rough surfaces, remove imperfections, and achieve a polished finish. The Abrasive Belt Metal Sanding Machinery offers numerous advantages over traditional sanding methods:

- Uniform sanding quality: The continuous motion of the abrasive belt ensures that the sanding pressure is evenly distributed, resulting in a uniform surface finish with minimal imperfections.

- Reduced material waste: As the sanding belt operates efficiently and uniformly, the amount of material lost during the process is minimized, making it a more cost-effective solution.

- Adjustable settings for various finishes: The machine’s adjustable speed and pressure controls allow operators to fine-tune the sanding process for different levels of smoothness, from light polishing to heavy grinding.

Key Features and Benefits of the 1300 cm Wide Belt Sanding Machine

The 1300 cm Wide Belt Sanding Machine with 30×533 Belt Sander offers a wide range of benefits to metalworking industries, including:

- Increased production efficiency: The wide belt design allows for faster processing of larger workpieces, reducing cycle times and improving overall throughput in industrial settings.

- Heavy-duty construction: Built with durable materials, the machine is designed to withstand harsh environments and continuous operations, ensuring a long service life and minimal maintenance requirements.

- Versatility in metal applications: The machine can handle a variety of metals, including steel, stainless steel, aluminum, and copper, making it suitable for diverse industries such as automotive, aerospace, and manufacturing.

- Ease of operation: The user-friendly interface and intuitive controls make it easy for operators to adjust settings, change belts, and monitor the sanding process.

Applications of the 1300 cm Wide Belt Sanding Machine

The 1300 cm wide belt sanding machine is well-suited for a wide range of metalworking applications, including:

- Deburring: The machine is ideal for removing sharp edges and burrs from laser-cut, plasma-cut, or sheared metal parts, improving safety and functionality.

- Finishing and polishing: Achieving smooth, refined finishes on metal surfaces, which is crucial for products like automotive components, structural parts, and consumer goods.

- Sanding welded joints: The machine effectively smooths welded seams and joints, ensuring that the final product meets high-quality standards.

- Surface preparation: The sanding machine is perfect for preparing metal surfaces for painting, coating, or further processing.

Conclusion

The 1300 cm Wide Belt Sanding Machine with 30×533 Belt Sander represents the cutting edge of abrasive belt metal sanding machinery. It combines high sanding capacity, precision, and durability to provide exceptional results in a variety of metalworking applications. Whether you are working with large-scale metal components or looking for a reliable machine to achieve consistent, high-quality finishes, this wide belt sanding machine offers the perfect solution. By investing in this advanced equipment, businesses can enhance their production capabilities, reduce operational costs, and improve the overall quality of their metal products.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao