Metal Sanding Machine Maintenance: Extend Lifespan and Efficiency

Proper upkeep not only enhances efficiency but also reduces the risk of breakdowns, helping companies avoid costly repairs. In this article, we outline essential maintenance steps that should be followed to keep metal sanding machines in optimal condition.

Table of Contents

Daily Maintenance:

Regular daily checks help identify potential issues before they affect the performance of the machine.

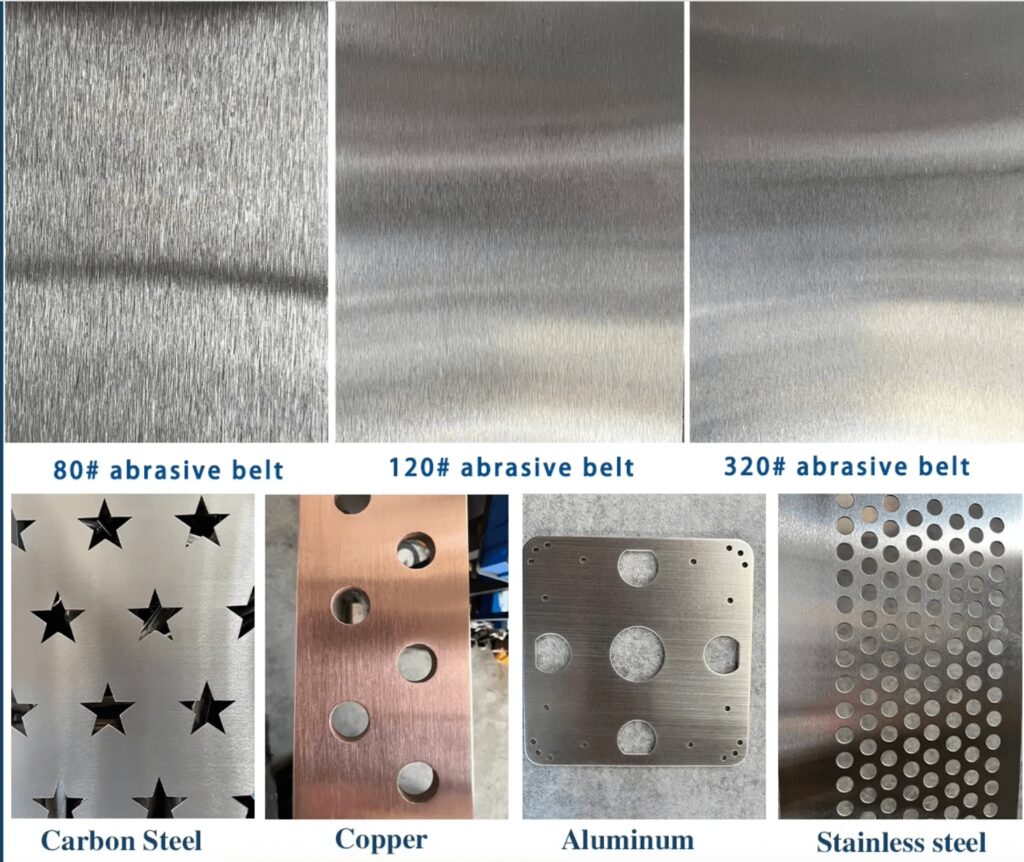

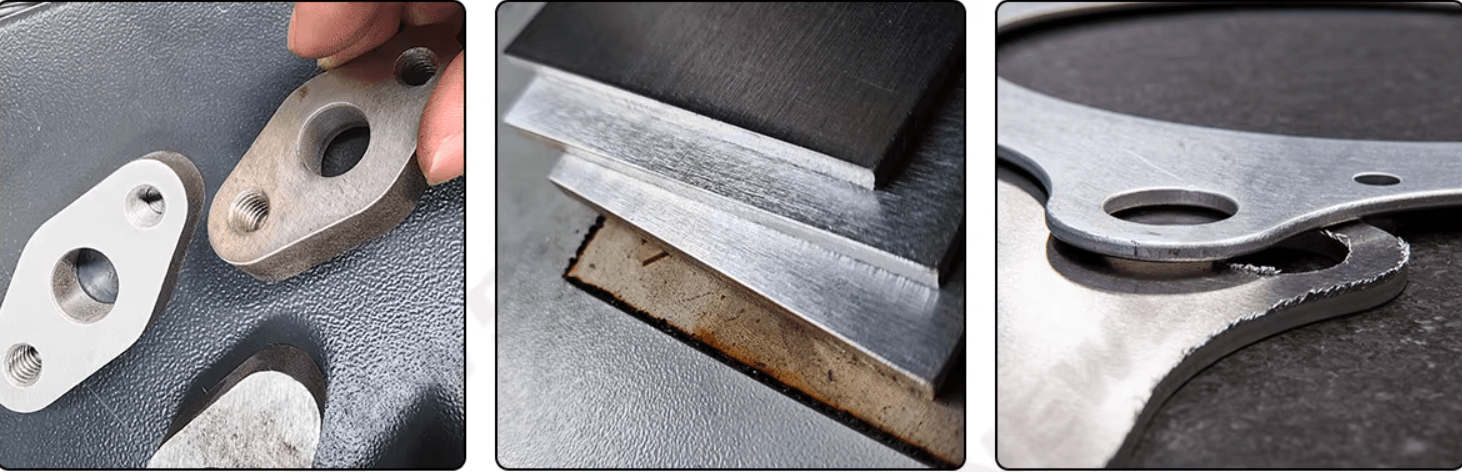

- Check Sanding Belt Wear: Regularly inspect the sanding belt for signs of wear or damage. Replace belts that are worn out to ensure that the machine performs effectively. This helps in maintaining the quality of the sanding process and prevents unnecessary strain on the motor.

- Clean the Machine: Keep the sanding machine clean by removing dust, metal shavings, and debris. Accumulated dust can impact the performance of the machine and create a hazardous work environment. Wipe down the machine daily to maintain smooth operation and prevent clogging in the dust collection system.

Lubrication and Cooling:

Lubricating and cooling the machine components are essential tasks to ensure smooth operation and prevent overheating.

- Lubrication of Moving Parts: Regularly apply lubricant to the machine’s moving parts, such as the drive shafts, bearings, and rollers. Proper lubrication reduces friction, enhances the performance of the transmission system, and prevents excessive wear.

- Cooling System Check: For machines working under heavy load or for extended periods, ensure that the cooling system is functioning properly. Check the cooling fans and coolant levels to avoid overheating, which could damage sensitive components or reduce the machine’s lifespan.

Replacement of Spare Parts:

Worn-out components should be replaced promptly to avoid compromising the machine’s efficiency and performance.

- Consumable Parts: Regularly replace consumable parts like the sanding belts, drive belts, and air filters. These parts wear out over time and must be replaced to maintain the optimal functionality of the machine.

- Other Essential Parts: Keep an eye on components like fans, power cables, and control switches. As these parts experience wear, replace them to ensure smooth and efficient operation. Keep a stock of commonly replaced parts to minimize downtime during repairs.

Preventive Measures:

Adopting preventive maintenance practices can reduce the likelihood of major breakdowns and extend the machine’s useful life.

- Regular Service Intervals: Schedule periodic professional servicing to address any potential issues that may not be apparent during routine checks.

- Proper Handling: Ensure that the machine is operated according to the manufacturer’s guidelines to avoid unnecessary strain or misuse.

Conclusion

Effective maintenance and care are key to maximizing the performance and lifespan of metal sanding machines. By implementing regular checks, lubricating moving parts, inspecting the motor and electrical systems, and replacing worn-out components, businesses can ensure their machines remain reliable and efficient over the long term. Routine maintenance not only reduces operational disruptions but also promotes a safer, more productive working environment.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao