Boost Laser-Cut Quality: Metal Sanders Ensure Smooth, Precise Finishes

However, achieving high-quality finished products often requires more than just laser cutting. Post-cut surfaces frequently exhibit burrs, oxidation layers, or minor unevenness, which can compromise subsequent processes and the final appearance. This is where metal sanders become an essential tool in elevating the quality of laser-cut parts.

Table of Contents

Key Benefits of Using Metal Sanders

Removing Burrs and Oxidation Layers

After laser cutting, metal edges often retain burrs or oxidation residues. These imperfections not only affect the appearance of the workpiece but can also lead to issues in subsequent processes like coating or welding. Metal sanders efficiently remove burrs, leaving surfaces smooth and clean.Improving Surface Roughness

Metal sanders are designed to reduce surface roughness, creating a refined finish that enhances adhesion for processes such as painting, plating, or welding. This ensures a more durable and aesthetically pleasing final product.Smoothing Edge Transitions

The sharp edges produced by laser cutting may pose safety risks during assembly or use. Metal sanders help round off these edges, improving both the usability and safety of the finished product.Increasing Efficiency

Compared to manual deburring or polishing, metal sanders deliver faster and more consistent results, significantly improving production efficiency and ensuring uniform quality across batches.

Selecting the Right Metal Sander

Choosing the right metal sander is critical for different materials and processing requirements:

- Stainless Steel: Opt for specialized wide-belt sanders to prevent surface scratches and ensure a flawless finish.

- Aluminum: Use high-precision sanders to minimize damage to the oxide layer and achieve a smooth surface.

- Iron and Copper: Select sanders with adjustable pressure settings to cater to varying hardness levels, ensuring even treatment across the workpiece.

Popular Metal Sanders for Laser-Cut Parts

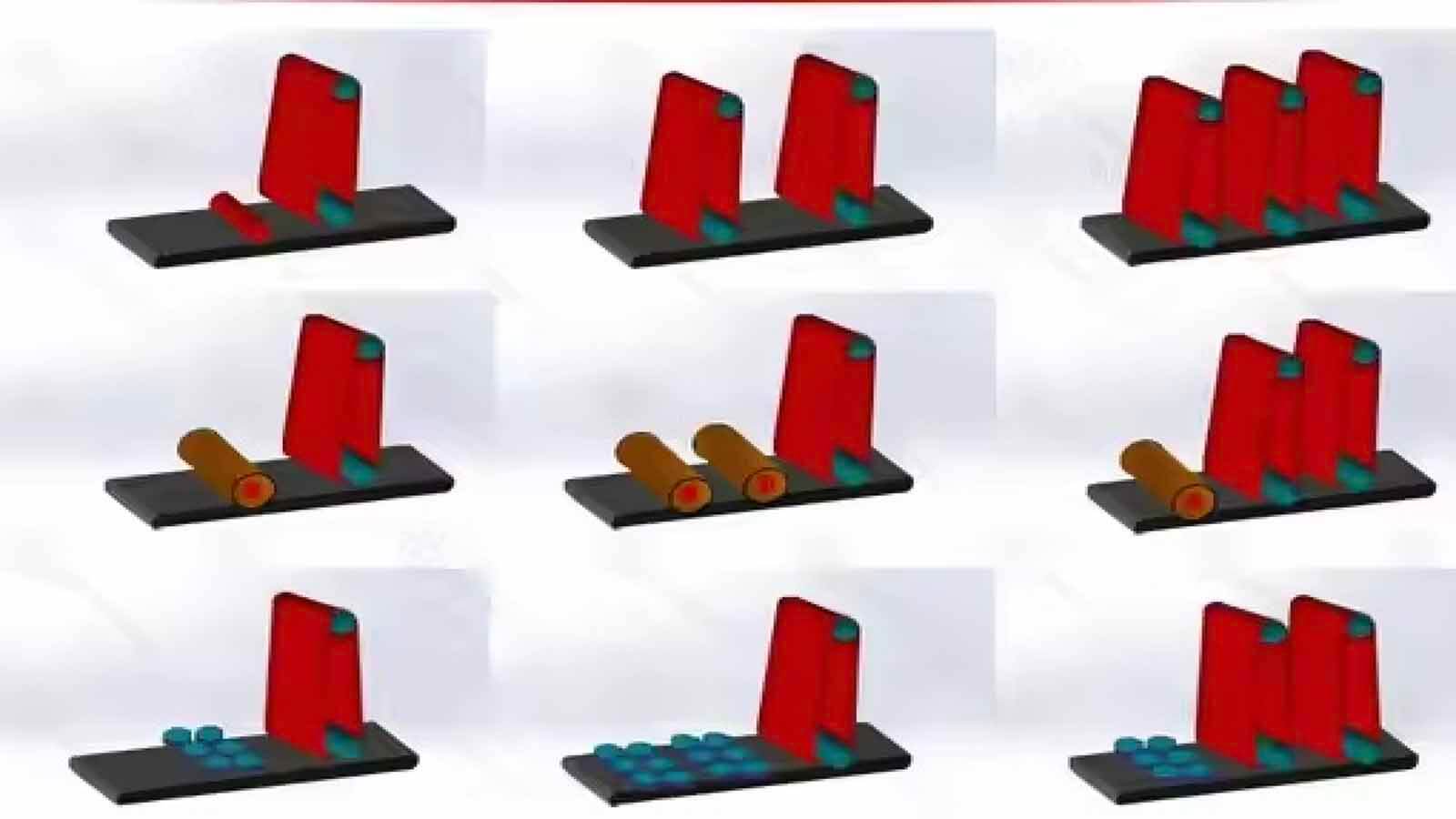

- Wide-Belt Sanders: Ideal for large, flat metal surfaces requiring uniform sanding.

- Edge Sanders: Perfect for refining edges and corners of laser-cut parts.

- Deburring Machines: Specially designed for removing burrs and sharp edges efficiently.

- Vibratory Sanders: Useful for small parts requiring gentle yet effective surface finishing.

Conclusion

Metal sanders are indispensable for enhancing the quality of laser-cut parts. They not only improve the surface finish and safety of the final product but also streamline production processes, making them an essential investment for any manufacturer aiming for top-tier results.

By integrating metal sanders into your workflow, you can deliver superior metal products to your customers while gaining a competitive edge in the market.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao