The Perfect Combination of Fiber Laser Cutting and Sanding

However, despite its advantages, laser-cut metal parts often require additional finishing processes to achieve the desired surface quality. This is where sanding comes into play. Combining fiber laser cutting with sanding processes allows manufacturers to address imperfections such as burrs, oxidation layers, and uneven textures, resulting in a superior final product

Table of Contents

The Role of Fiber Laser Cutting

Fiber laser cutting has gained significant popularity in metalworking due to its precision, speed, and ability to cut through various metals with minimal material distortion. The process uses a high-powered laser beam to melt or vaporize the material along the cut line, leaving a clean, smooth edge. However, while the cutting process itself is efficient, it does not always leave the metal part in a condition suitable for direct use in applications that require a high level of finish, such as automotive, aerospace, or decorative products.

The Need for Sanding in Laser-Cut Parts

Despite the precision of fiber laser cutting, several issues may still arise on the cut edges:

Burr Formation: As the material is cut, thermal effects can cause burrs—small, sharp protrusions—on the edges of the metal. These burrs, if not removed, can interfere with assembly, cause safety concerns, and degrade the product’s appearance.

Oxidation: During the cutting process, high temperatures can expose the metal to oxygen, resulting in an oxidation layer. This layer not only affects the aesthetic appearance but also diminishes the material’s integrity and can hinder the adhesion of coatings or welding.

Surface Texture: Even though laser cutting produces relatively smooth edges, some parts may still have minor surface irregularities or roughness. For parts requiring a high-quality finish, sanding ensures uniformity and a superior appearance.

Sanding: The Perfect Solution

Sanding is an essential finishing process that complements fiber laser cutting. Here’s how it enhances the final product:

Burr Removal: Sanding effectively removes any burrs left from the cutting process, providing smoother edges and reducing the risk of injury or improper fitting during assembly.

Oxidation Layer Removal: Sanding removes oxidation and residue from the cutting process, revealing the original metal shine. This process is especially important for products that require painting, coating, or welding, as the clean surface ensures better adhesion.

Improved Surface Quality: Sanding improves the overall texture of the metal, creating a smoother, more uniform surface that enhances the part’s visual appeal and performance in subsequent processes.

Combining Laser Cutting and Sanding for Optimal Results

By integrating sanding with fiber laser cutting, manufacturers can achieve parts that are not only precisely cut but also exhibit the highest level of quality and finish. This combination ensures that parts are free from burrs, oxidation, and surface imperfections, making them suitable for high-end applications in industries such as automotive, aerospace, and decorative metalwork.

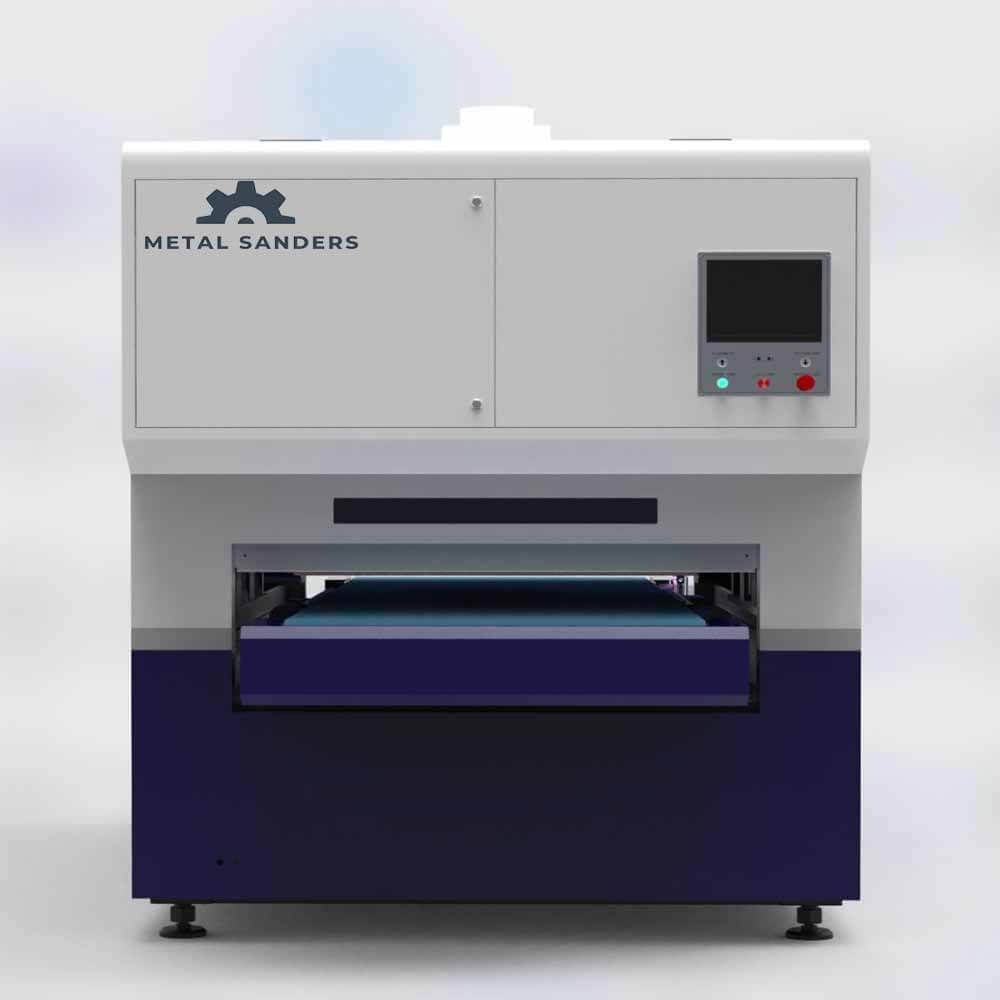

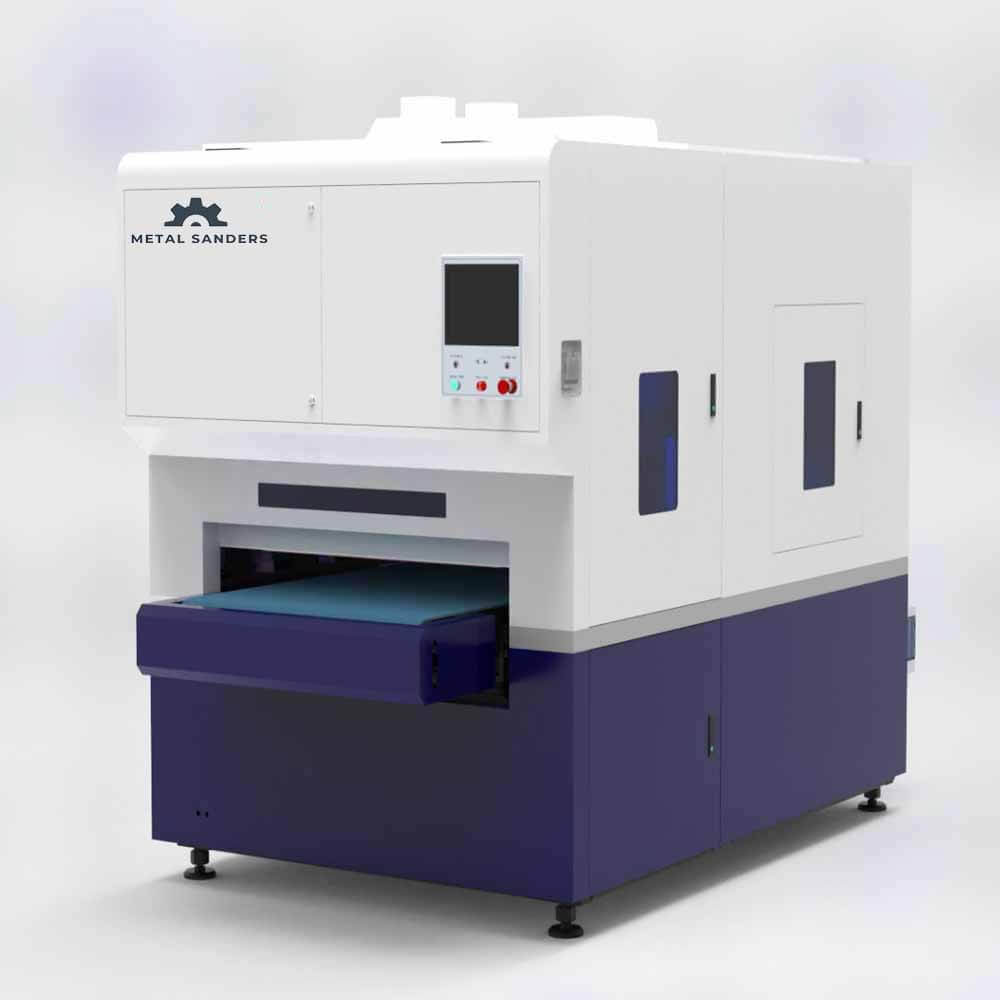

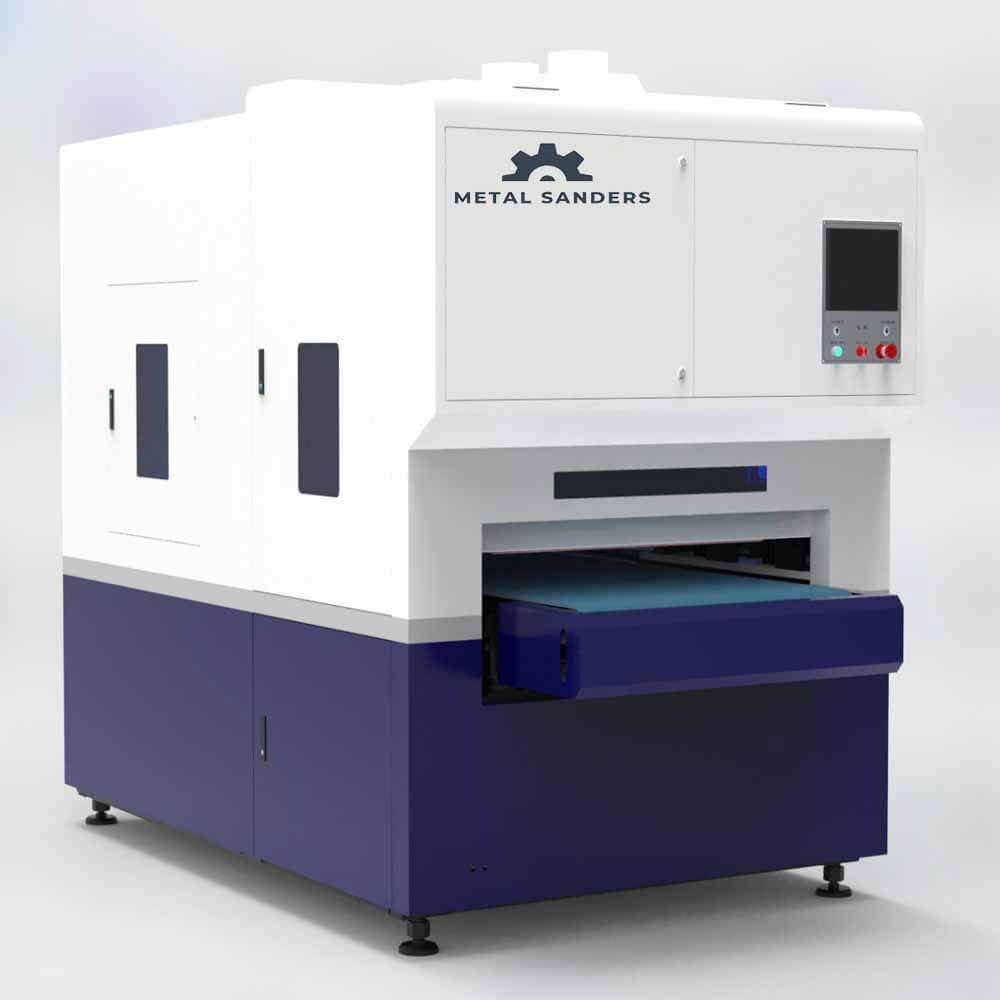

The key to achieving this is selecting the right sanding equipment. For larger sheets or plates, wide-belt sanders are ideal for quick and even processing. For smaller or more intricate parts, handheld or tabletop sanders offer the control needed for detailed finishing. Additionally, sanding equipment with efficient dust collection systems helps maintain a cleaner environment and saves on energy consumption.

Conclusion

The integration of fiber laser cutting with sanding processes is a powerful combination for achieving high-quality metal parts. While fiber laser cutting offers unparalleled precision and speed, sanding ensures that any imperfections—such as burrs, oxidation, and rough textures—are addressed, resulting in a clean, uniform surface. This combination of technologies is vital for industries that demand the highest standards of metal parts. By optimizing the use of both processes, manufacturers can deliver products that meet the exacting requirements of customers and industries alike, ensuring a competitive edge in the market.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao