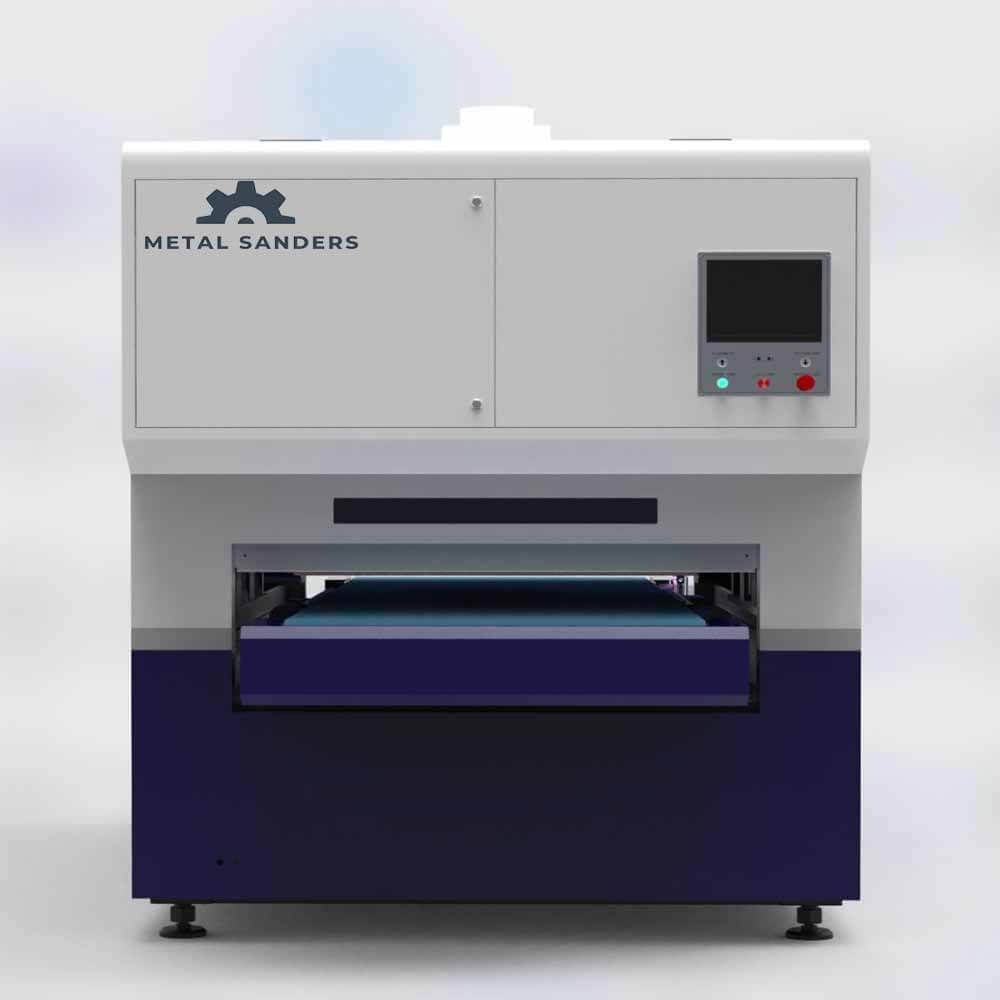

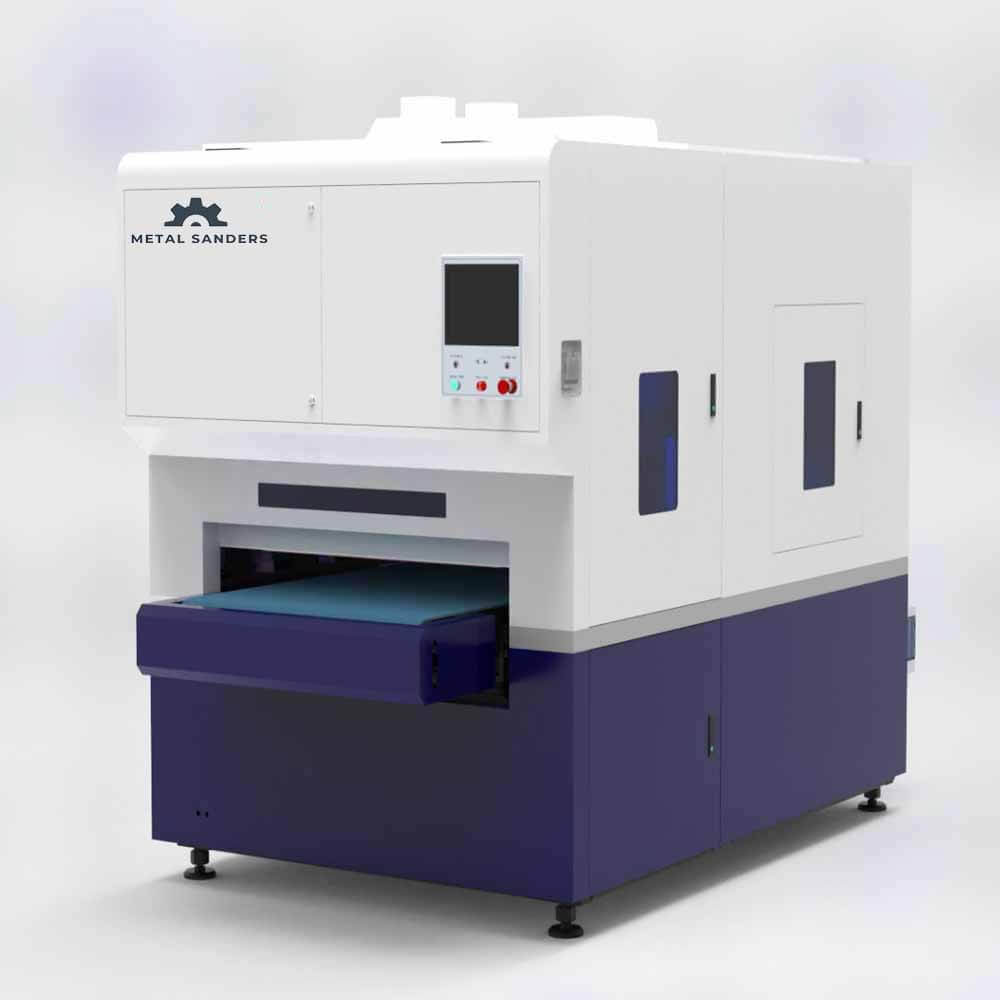

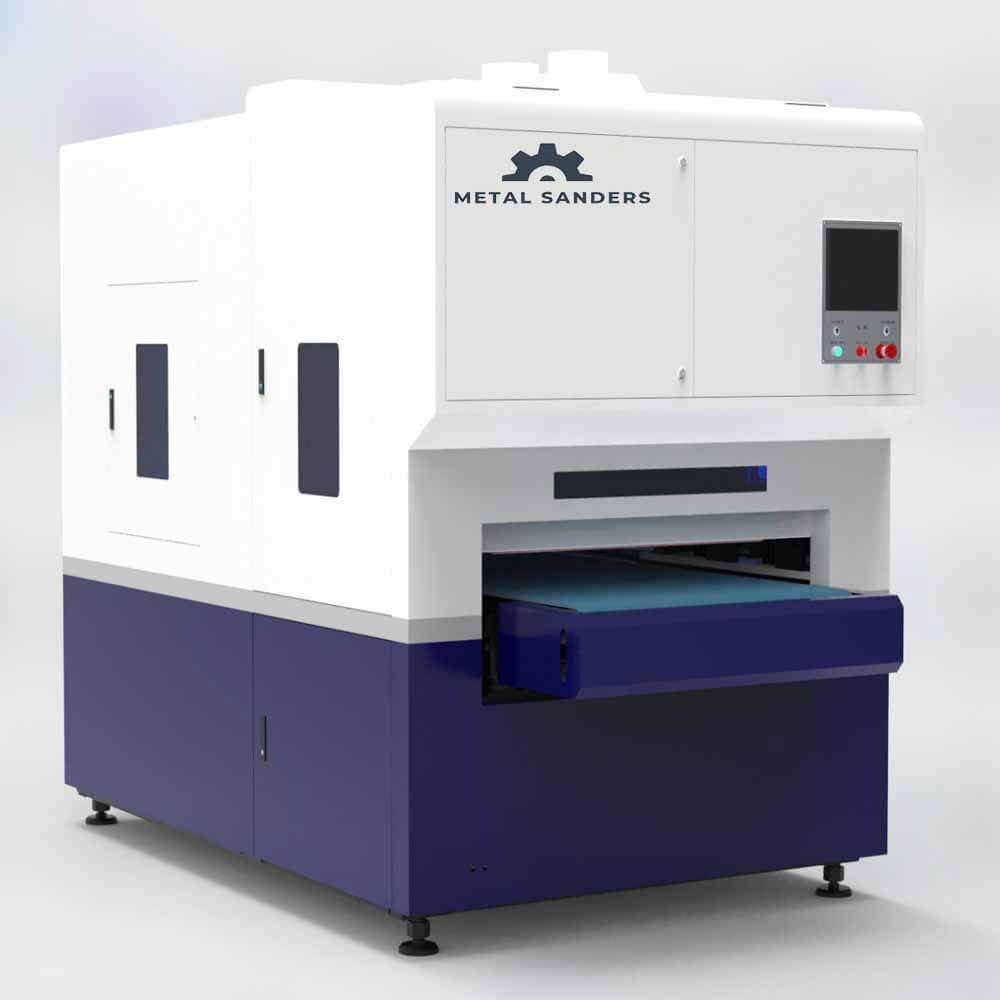

How to Sand Stainless Steel in a CNC Metal Sanding Machine

. Fortunately, CNC metal sanding machines offer a precise and efficient way to restore the metal to its original shine. Here’s a step-by-step guide to sanding stainless steel using a CNC metal sanding machine:

Table of Contents

Prepare the Surface

- Clean the Stainless Steel: Begin by cleaning the stainless steel surface thoroughly. Use a degreaser or a mild detergent to remove any oils, dirt, or grease. This ensures that no contaminants will affect the sanding process.

- Dry the Surface: Wipe down the surface with a clean cloth to remove any remaining water or residue.

Choose the Right Sanding Abrasive

- For sanding stainless steel, start with a medium-grit abrasive (around 120-180 grit). This will help remove minor scratches and imperfections without damaging the surface.

- If deeper scratches are present, start with a coarse grit (60-80 grit), then gradually move to finer grits (220-240 grit) to refine the finish.

- Abrasive Type: Use abrasives specifically designed for metalworking, such as aluminum oxide or zirconia abrasives, which are ideal for tough metals like stainless steel.

Set Up the CNC Metal Sanding Machine

- Mount the Abrasive: Secure the appropriate sanding belt or disc onto the CNC metal sanding machine.

- Adjust the Machine Settings: Set the machine’s speed and pressure settings based on the abrasive and the level of sanding needed. For finer finishes, use a slower speed to avoid overheating and potential warping of the metal.

Sanding Process

- Start the Machine: Begin the sanding process by carefully moving the stainless steel under the sanding surface. If the machine is equipped with a conveyor system, ensure the metal moves at a steady, controlled pace.

- Work in Even Passes: Make even, consistent passes over the surface to avoid creating uneven areas. Keep the machine moving at all times to prevent hotspots that could cause discoloration or warping.

- Multiple Passes: You may need to pass the stainless steel through the machine multiple times, gradually working your way up from coarse to fine grits to achieve the desired finish.

Inspect the Surface

- Check for Scratches: After sanding, inspect the surface for any remaining scratches. If necessary, repeat the sanding with a finer abrasive to refine the surface and remove any imperfections.

- Polish the Metal: For a high-gloss, mirror-like finish, consider polishing the stainless steel after sanding. You can use a polishing compound with a finer abrasive on the CNC machine to enhance the metal’s shine.

Clean the Finished Surface

- Once the sanding is complete, clean the stainless steel surface again to remove any dust or debris.

- Apply a protective coating or polish to maintain the smooth, glossy finish and prevent future scratches or discoloration.

Conclusion

Sanding stainless steel using a CNC metal sanding machine is an effective and precise method to remove scratches and imperfections while restoring its sleek, polished appearance. By following the proper steps, from preparing the surface to selecting the right abrasives and machine settings, you can achieve professional results with minimal effort. Whether you’re working on a small piece or an industrial application, this process ensures your stainless steel maintains its durability and contemporary aesthetic. Keep your metal surfaces shining and scratch-free with the right tools and techniques!

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao