Can You Use Belt Sanders on Metal

Whether you’re a professional fabricator or a DIY enthusiast, belt sanders can streamline your metal finishing processes. This article will explore the potential of belt sanders for metal, covering their uses, benefits, and best practices.

Table of Contents

What Are Belt Sanders?

Belt sanders are power tools that use continuous abrasive belts to grind, smooth, or shape materials. Their design allows for efficient material removal and precise control, making them a staple in both woodworking and metalworking industries.

Can You Use Belt Sanders on Metal?

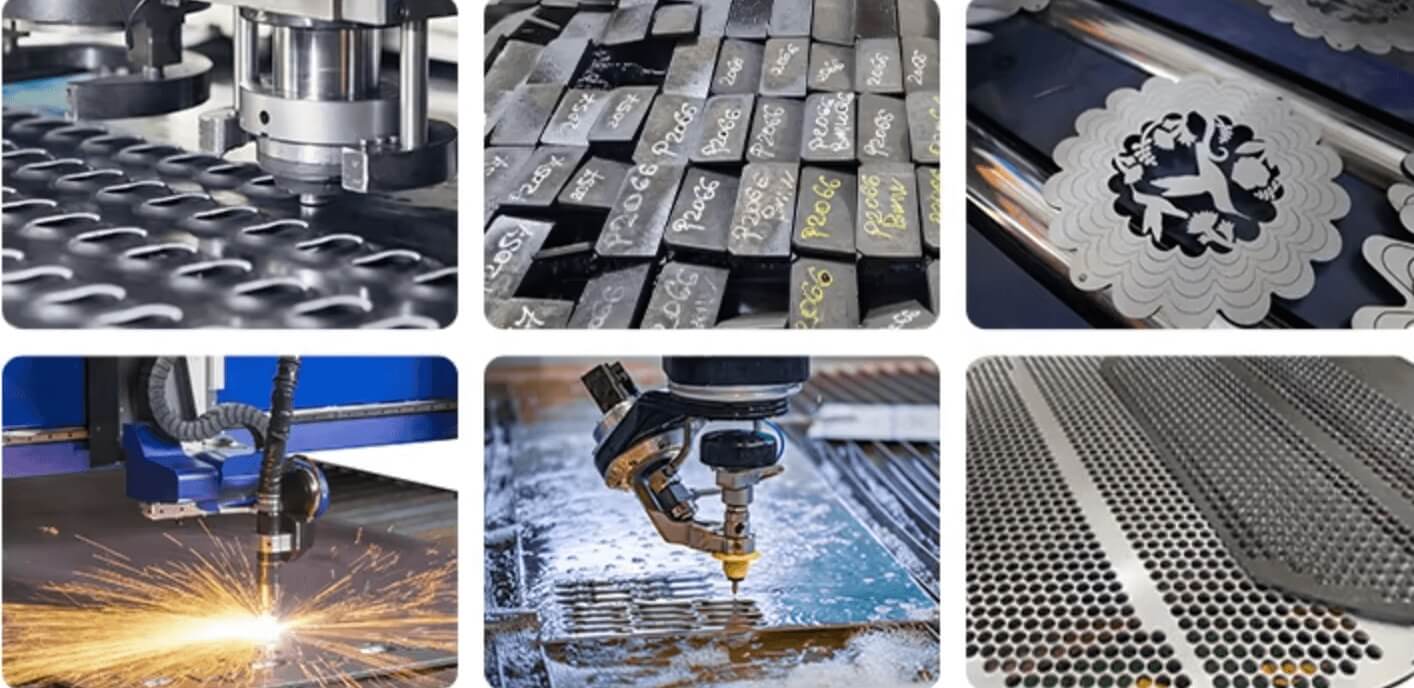

The short answer is yes. Belt sanders are highly effective for working on various metal surfaces, provided the correct setup and techniques are used. They can handle tasks such as:

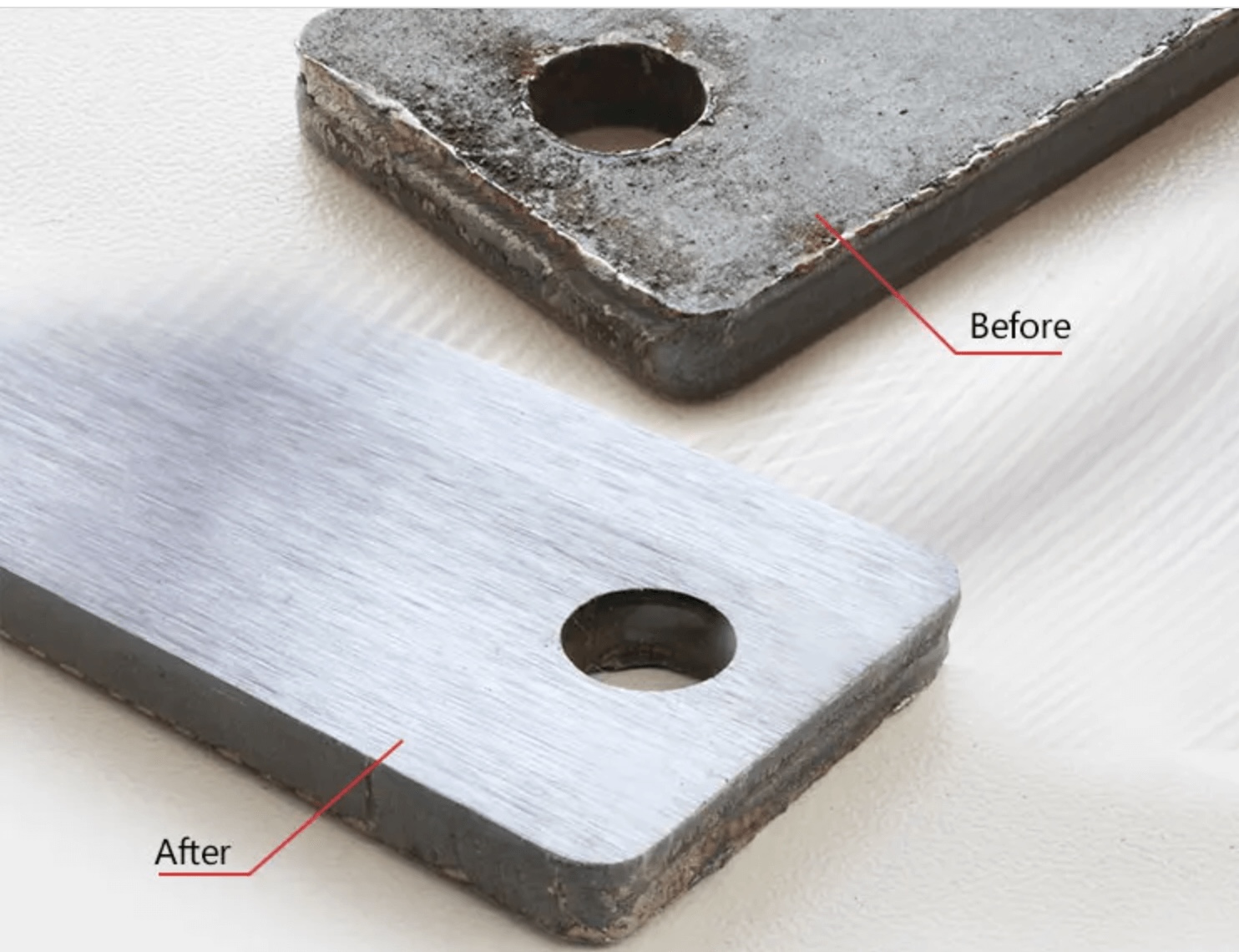

Surface Preparation:

- Removing rust, paint, or corrosion from metal surfaces.

- Preparing metal for welding or coating applications.

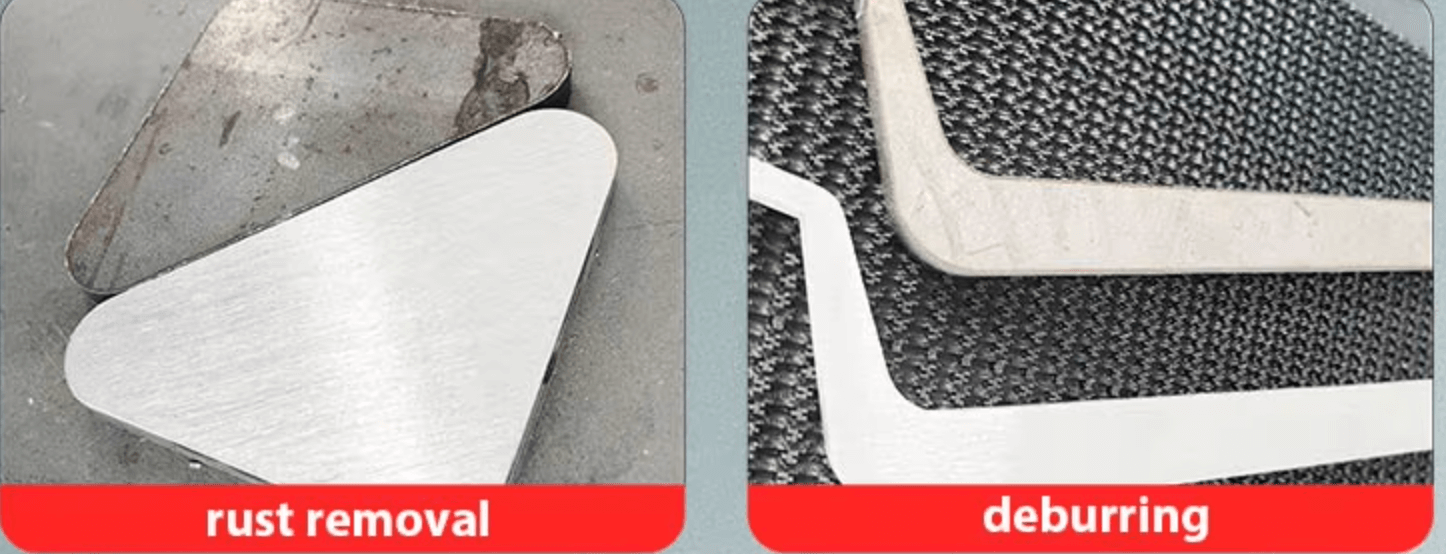

Deburring:

- Smoothing sharp edges or burrs after cutting or machining.

Shaping and Contouring:

- Refining metal parts to achieve specific shapes or angles.

Polishing:

- Creating a smoother, more refined finish when used with finer grit belts.

Best Practices for Using Belt Sanders on Metal

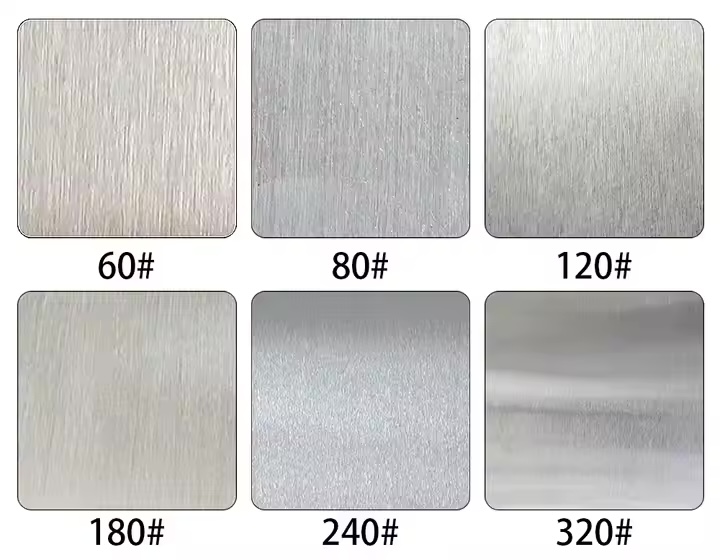

1. Choose the Right Abrasive Belt

Different metals require specific abrasive materials:

- Zirconia: Excellent for high-pressure grinding and long-lasting use.

- Ceramic: Ideal for heavy-duty sanding and harder metals.

- Aluminum Oxide: Suitable for general-purpose metal sanding.

2. Adjust Speed Settings

Lower speeds are better for metals to reduce heat buildup, which can cause warping or discoloration. Many belt sanders have variable speed controls for this purpose.

3. Ensure Proper Cooling

Overheating metal can weaken its structure. Use cooling techniques like water sprays or pauses during operation to prevent heat damage.

4. Maintain Safety

- Wear protective gear, including goggles and gloves.

- Ensure good ventilation to avoid inhaling metal dust.

Advantages of Using Belt Sanders on Metal

1. Efficiency

Belt sanders remove material quickly, saving time compared to manual methods.

2. Versatility

With the right abrasive belts, they can handle a variety of tasks, from rough grinding to fine polishing.

3. Precision

Belt sanders allow for controlled material removal, essential for detailed work or achieving specific tolerances.

Conclusion

Belt sanders are invaluable tools for metalworking, offering efficiency, precision, and versatility. Whether you’re deburring edges, polishing surfaces, or preparing metal for further processing, they deliver reliable results when used correctly. By choosing the right abrasive belts, adjusting settings appropriately, and following safety guidelines, you can maximize the potential of belt sanders in your metalworking projects.

Invest in a quality belt sander, and elevate your metalworking capabilities with this powerful tool!

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: info@metalsanders.com

- Address: Wangtai Gongye Industry, Qingdao