1300 Metal Sander Machine

- Model: R-R1300

- Customized: Accept

- Style: Wet/Dry

- Standard: Meet CE Standards in Terms of Quality & Safety

- Supplity: 360 Sets / Month Waiting for Sale In Stock

Description of 1300mm Metal Sanders machine

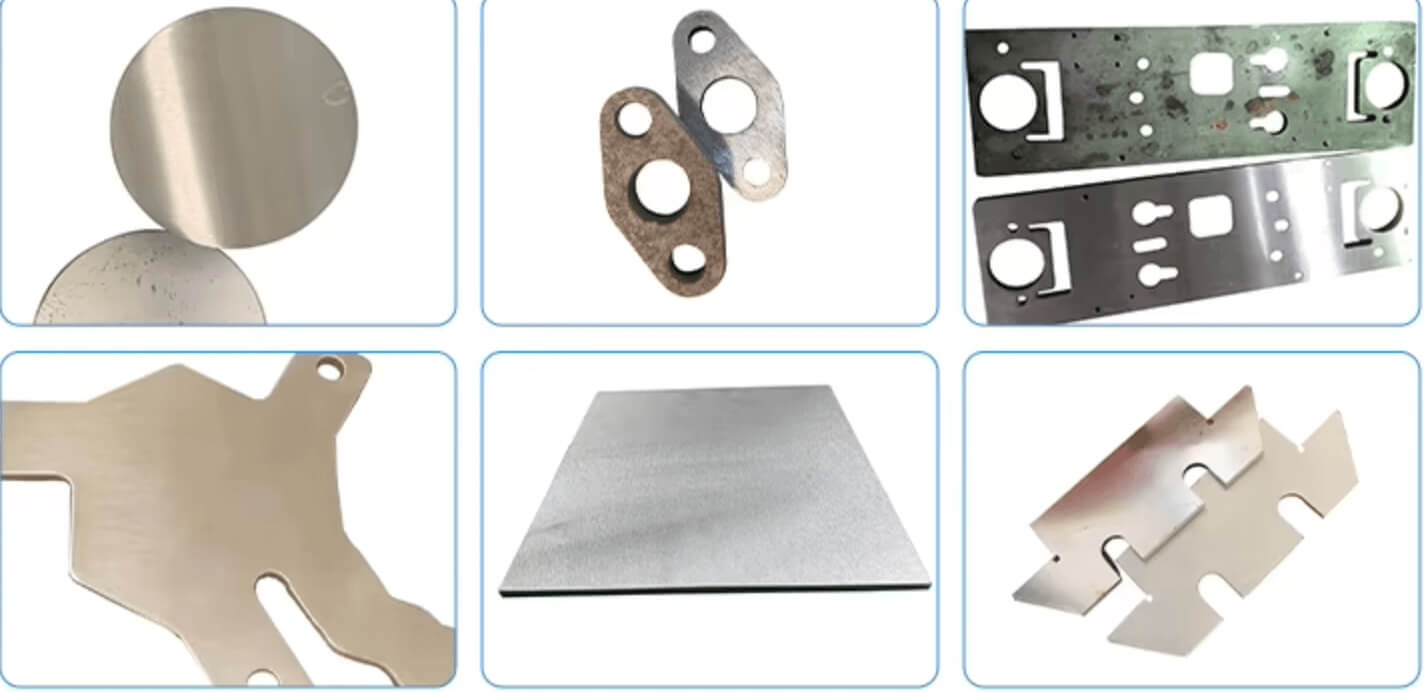

Designed to pair seamlessly with laser cutting machines, CNC stamping, and various CNC machining or other manufacturing processes, this deburring production line efficiently handles edge finishing. The equipment utilizes linear processing combined with multiple sets of sand line wheels for rotation, revolution, and alternating motion, ensuring uniform removal of surface burrs, contour edges, and hole edges while providing consistent chamfering.

Processes like cutting, drilling, laser engraving, and milling often generate burrs, hot slag, or residue on workpiece edges. Therefore, selecting the right deburring machine is essential for achieving clean and precise results.

Features of 1300mm Metal Sanders machine

- Precise Deburring and Edge Rounding: Ensures clean internal and external contours without damaging polished, brushed, or coated sheet metal surfaces, thanks to flexible processing that protects surface finishes and film coatings.

- Versatile Burr Removal: Ideal for eliminating burrs from flat or near-flat sheet metal parts processed via CNC punching or shearing, laser cutting, or flame/plasma cutting, including slag removal.

- Streamlined Grinding Process: Replaces traditional methods like filing or manual grinding with electric or pneumatic tools, delivering more uniform results, improved safety, reduced labor costs, and enhanced production efficiency.

- Adjustable Grinding Precision: Allows for precise control of grinding and stroke parameters, enabling the removal of sharp edges and contours without harming surface finishes. Perfect for materials like galvanized steel, coated aluminum, copper, and stainless steel.

- Advanced Workpiece Adsorption Technology: Features turbo vacuum adsorption for secure holding during grinding, accommodating flat and shaped workpieces, even after bending. Magnetic adsorption is also available, reducing power consumption, enhancing efficiency, and preventing system blockages.

- User-Friendly Control System: Equipped with a Delta PLC control system, simplifying operation and allowing easy adjustments to grinding parameters for optimal results.

- Energy-Efficient Design: Optional disk adsorption reduces power consumption significantly, while compatibility with standard consumables and custom sand wheels boosts efficiency and meets unique product needs.

Parameters of 1300mm Metal Sanders machine

| Model | R-R630 | R-R1000 | R-R1300 |

| Working width(mm) | 630 | 1000 | 1300 |

| Min.Working length(mm) | 300 | 300 | 300 |

| Working thickness(mm) | 0-110 | 0-110 | 0-110 |

| First motor(kw) | 7.5 | 11 | 18.5 |

| Second motor(kw) | 7.5 | 15 | 22 |

| Total Power | 19.97 | 36.55 | 43.85 |

| Transmission motor power(kw) | 1.1 | 2.2 | 4 |

| Abrasive belt size(mm) | 650*1900 | 1020*2200 | 1320*2200 |

| Overall dimensions(mm) | 1800*1200*2100 | 1900*1600*2100 | 2350*2450*2100 |

| Weight(kg) | 1300 | 1800 | 2500 |

Details of 1300mm Metal Sanders machine

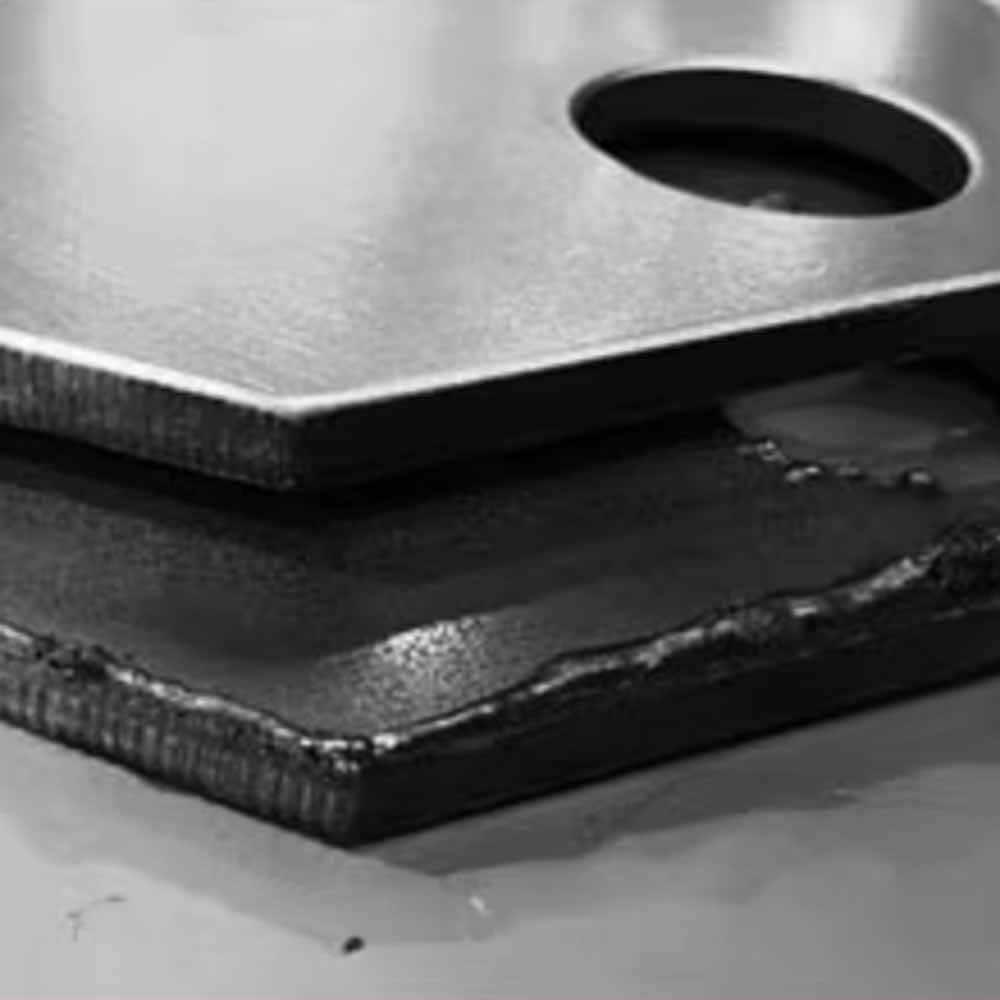

Sand Rack

The front sand frame is the adjustable steel roller and the rear sand frame is the combined structure of the rubber roller mat, which is suitable for the constrant thickness and and fine polishing of various panels

Conveyor Belt

Working table for the thickend marble, conveyor belt for five layers of rubber material, not afraid of rain, not afraid of sun, long service life.

Internal Circuit

All the electrical parts are made of Chint electric applicances with stable performance. The machine internal wire connectrion is clear, no clutter.

Products details of 1300mm Metal Sanders machine

Deoxidizing

Round Edge Chamfer

Mirror Drawing

Presicion Grinding

Slag Off and Chanfer