1000mm Wide Belt Sander and CNC Polishing Machines for Metal Sheets

Let’s dive into their functions, advantages, and how to choose the right solution for your operations.

Table of Contents

What Is a 1000mm Wide Belt Sander?

A 1000mm Wide Belt Sander is a robust, high-efficiency sanding machine built for processing large-format metal sheets. Its wide working surface is ideal for handling stainless steel panels, aluminum sheets, and iron components with consistent pressure and control. It’s an essential tool for surface leveling, paint removal, and pre-polishing.

Core Advantages:

Large working width (1000mm) for processing wide sheet metal

Powerful motor ensures high-speed material removal

Consistent surface roughness for better coating adhesion

Ideal for batch processing and industrial-scale applications

Technical Parameters of the 1000mm Wide Belt Sander

This model can be customized with wet/dry sanding, vacuum table, or automatic loading/unloading based on your production requirements.

| Item | Specification |

|---|---|

| Working Width | 1000 mm |

| Working Thickness | 0.8 – 100 mm |

| Abrasive Belt Size | 1000 × 1900 mm |

| Feed Speed | 5 – 30 m/min (adjustable) |

| Main Motor Power | 22 kW (customizable) |

| Brush/Polishing Motor | 4 kW × 2 |

| Feeding Motor | 1.5 kW |

| Dust Collection Port | Φ 150 mm × 3 |

| Machine Dimensions | 2500 × 1800 × 2200 mm (L×W×H) |

| Total Weight | Approx. 2500 kg |

Why Choose a Belt Brush Grinding Deburring Finishing Machine?

This machine integrates brushing, grinding, deburring, and finishing into one continuous process. It’s designed for versatility and is widely used in industries like HVAC, elevator panels, decorative metals, and appliance housings.

Key Capabilities:

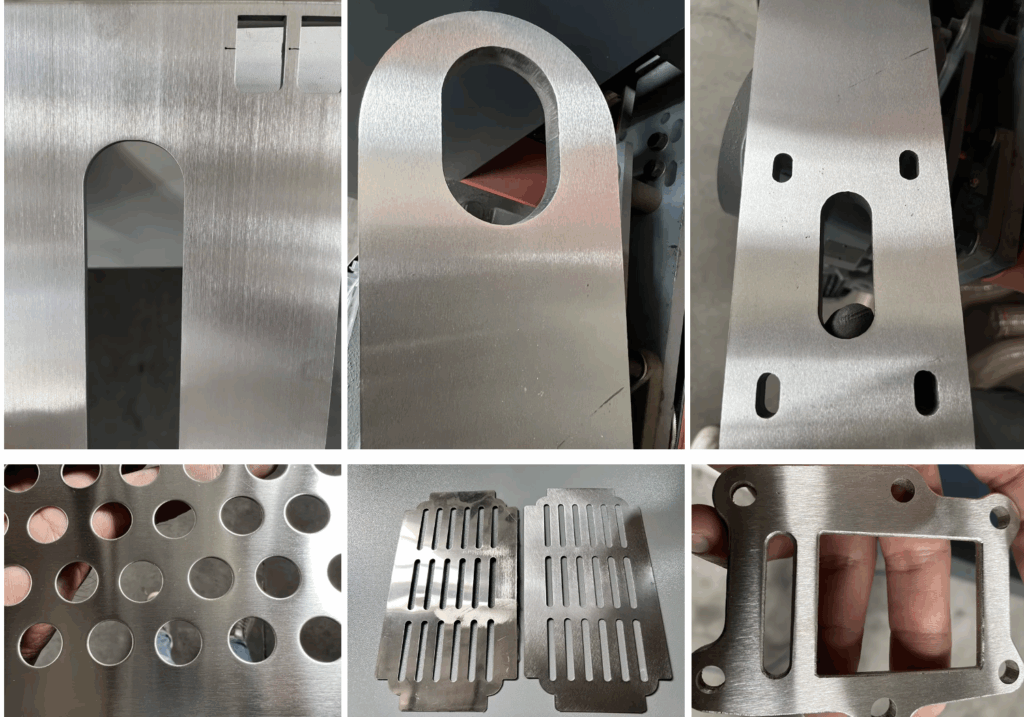

▶ Deburring sharp edges from laser/plasma cut parts

▶ Surface brushing for aesthetic grain patterns

▶ Edge rounding for safety and function

▶ Dry or wet processing with abrasive belts and brush rollers

Whether you’re working with carbon steel, stainless steel, or aluminum, this machine enhances safety, reduces post-processing time, and improves surface quality.

CNC Polishing Machine for Stainless Steel, Aluminum, and Iron Sheet Metal Parts

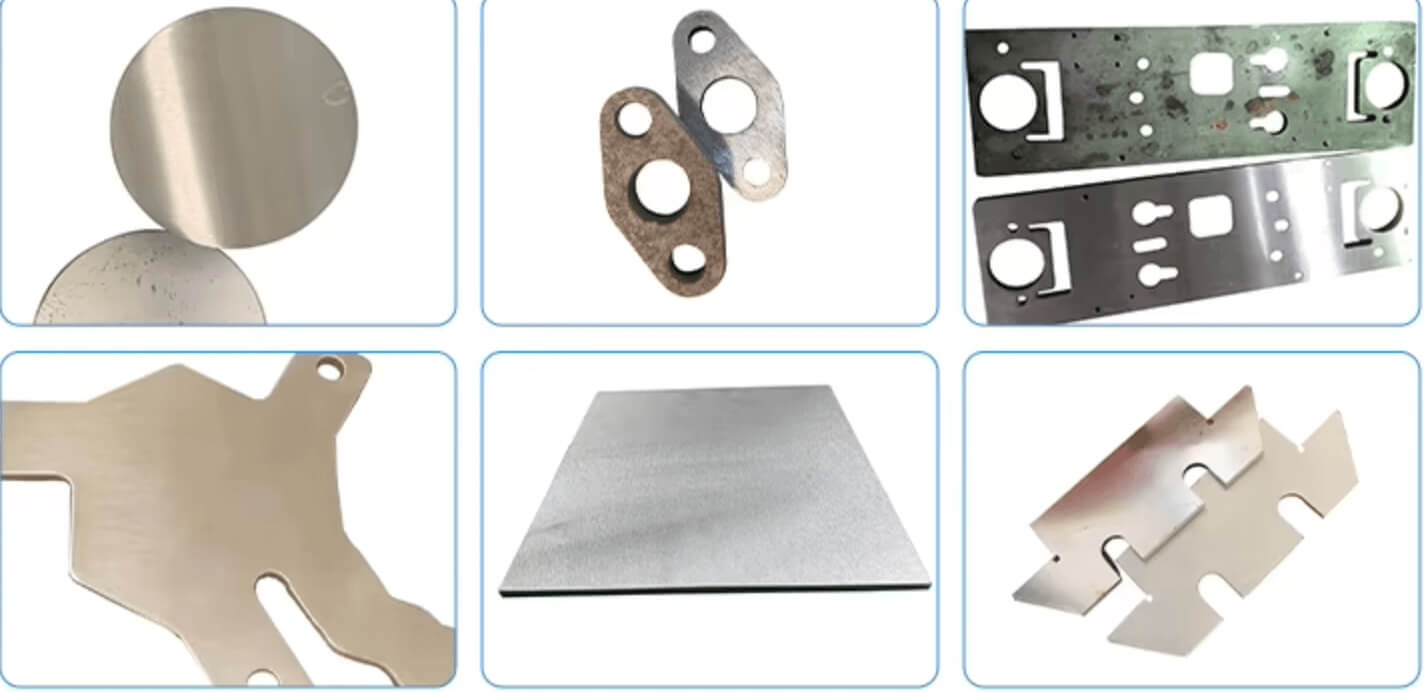

A CNC Polishing Machine automates the polishing process using programmed movement paths for unmatched consistency and efficiency. These machines are especially valuable for handling complex geometries, large volumes, or components requiring a mirror-like finish.

Major Benefits:

CNC control ensures precision and repeatability

Perfect for decorative panels, appliance covers, and signage

Compatible with various polishing abrasives (flap wheels, scouring pads, felt wheels)

Improves productivity and reduces labor dependence

Applications in Modern Industry

These machines are essential for various industries:

Architecture: Stainless steel façade and elevator panels

Appliances: Polished aluminum and steel parts

Metal Furniture: Smooth edges and brushed finishes

Automotive: Deburring stamped or cut parts

Custom Fabrication: Polished custom signage or artwork

How to Choose the Right Machine?

When selecting a 1000mm Wide Belt Sander, Belt Brush Finishing Machine, or CNC Polishing Machine, consider the following factors:

Material type: Stainless steel, aluminum, mild steel, or copper

Surface treatment goal: Rough grind, satin finish, or mirror polish

Sheet size and throughput: For large volumes, prefer wide belt or CNC models

Abrasive compatibility: Confirm support for belts, brushes, wheels, and pads

Automation level: Choose CNC models for high precision and labor savings

Dust or water filtration: Ensure safe and clean operation

Why Partner with Us?

We are a professional metal surface treatment machine manufacturer offering:

Precision-built 1000mm Wide Belt Sanders

Integrated Belt Brush Grinding Deburring Machines

Customizable CNC Polishing Machines for metal sheet processing

Our Commitment:

Factory-direct prices with top-quality builds

Fast international shipping

Lifetime technical support

Custom configurations for your industry

One-on-one expert consultation for optimal machine selection

Conclusion

From initial sanding to mirror polishing, modern metal processing demands reliable, high-performance equipment. Whether you’re finishing elevator panels, appliance parts, or custom metalwork, the right 1000mm wide belt sander, belt brush deburring machine, or CNC polishing system ensures consistency, speed, and superior results.

Don’t settle for less. Partner with a professional you can trust.

👉 Contact us today for a personalized quote and expert guidance tailored to your production needs.

Products Categories

Recently News

Why Choose Us

- 16 years of expertise in CNC equipment production.

- Over 22 years of experience from our skilled technical team.

- Trusted in 100+ countries with 800+ installations globally.

- 10,000 square meter manufacturing facility, equipped for large-scale production.

- A dedicated team of 20+ international sales representatives.

- Round-the-clock support with 24/7 after-sales service.

- A rigorous quality assurance system to ensure top-notch products.

- A collaborative approach fostering success for partners, clients, and staff.

- Comprehensive turnkey solutions integrating manufacturing, service, and sales.

- Designed to handle all types of metal workpieces, meeting diverse industry needs.

Contact Us

- Tel:86-531-88804531

- Phone:86 15562582965

- Email: [email protected]

- Address: Wangtai Gongye Industry, Qingdao